Influence of corrosion of the first circuit elements on the distribution of sediments in the circulation tract of the SMR 160 reactor

DOI:

https://doi.org/10.15587/2706-5448.2025.326512Keywords:

modular reactor, water-chemical regime, corrosion, sediment, austenitic steel, zirconiumAbstract

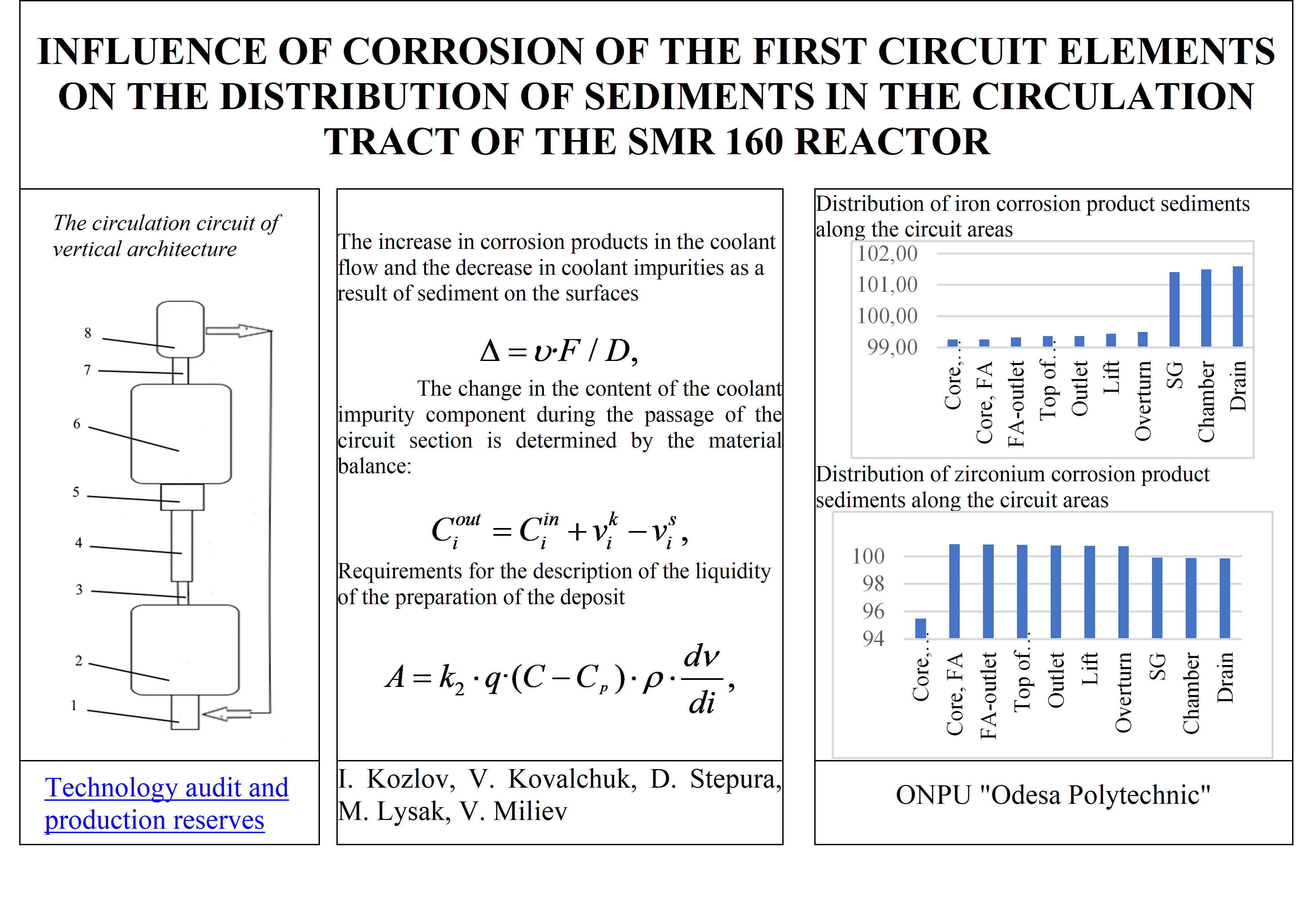

The object of research is the circulation path of a water-water small modular reactor. The work is aimed at assessing the influence of corrosion intensity on the formation of sediments on the surfaces of the first circuit of the SMR 160 reactor module. The analysis of the circuit structure was performed, the intensity of corrosion destruction and the intensity of sediments on the local sections of the circuit are evaluated. The circulation circuit of vertical architecture, the movement of the coolant in which excites thermal pressure, created by heating in the core and cooling in the steam generator.

The methodology is based on the principle of material balance of the transition of corrosion products into the coolant and their sediment on the circuit surface. To estimate the speed of corrosion the results of complex studies conducted at stations in normal operation and on the physical models of sections of the first circuit in the laboratory were used. Estimation of the speed of sediments is performed according to the ratios that take into account the impact of the concentration of the sedimented substance in the coolant, the thermal load of the site and the consumption of the coolant.

The calculations showed that the main source of iron oxides in the circuit is the surface of the steam generator, causing the average value of their concentration in the final areas, and zirconium oxides come from the surface of the core and retain the concentration close to the average along the entire tract.

The research results showed that the high corrosion stability of the structural materials of the circuit significantly limits the transition and accumulation of corrosion products in the coolant. In turn, low concentrations of corrosion products in the coolant restrain the formation of their sediments on the surfaces of the core and steam generator. The values of the surface density of sediments and their average thickness are estimated.

Analysis of corrosion processes of structural materials and the distribution of their sediments in the circuit allow to predict the level of radiation contamination and to plan the service life of the system.

The presented technique allows to evaluate the effectiveness of the water -chemical regime used.

References

- Malohulko, Yu. V., Slidenko, M. O. (2024). Perspektyvy vprovadzhennia tekhnolohii. vykorystannia malykh modulnykh. Materialy LIII naukovo-tekhnichnoi konferentsii pidrozdiliv VNTU. Available at: https://ir.lib.vntu.edu.ua/bitstream/handle/123456789/42136/19751.pdf?sequence=3&isAllowed=y

- Maltseva, T., Lukashyn, S., Shyshuta, A., Bakanov, V. (2024). Water Chemistry at NPP Units. Nuclear and Radiation Safety, 1 (101), 59–68. https://doi.org/10.32918/nrs.2024.1(101).06

- Medvediev, R. B., Skladannyi, D. M., Pustovyi, D. O. (2019). Modeliuvannia zminy kontsentratsii okysnykiv u pershomu konturi reaktora VVER-1000. Informatsiine suspilstvo: tekhnolohichni, ekonomichni ta tekhnichni aspekty stanovlennia, 43 (2), 61–62. Available at: http://www.konferenciaonline.org.ua/data/downloads/file_1638480082.pdf

- Medvediev, R. B. (2018). Suchasna teoriia upravlinnia khimiko-tekhnolohichnymy protsesamy. Kyiv: KPI im. Ihoria Sikorskoho, Vydavnytstvo “Politekhnika”, 208.

- Vodennikova, O., Vodennikova, O., Rahalevych, A. (2023). Corrosion process of copper-nickel alloy in pipes capacitors of the second circuit of the NPP. Scientific Journal “Metallurgy”, 1, 48–56. https://doi.org/10.26661/2071-3789-2023-1-07

- Medvediev, R. B., Skladannyi, D. M., Pustovyi, D. O. (2019) The approximate thermal calculation of the steam generator at the NPP with the VVER-1000 reactor. Kompiuterne modeliuvannia v khimii i tekhnolohiiakh ta systemakh staloho rozvytku – KMKhT-2019. Kyiv: NTUU “KPI”, 118–121.

- Krasnorutskyi, V. S., Petelhuzov, I. A., Hrytsyna, V. M., Zuiok, V. A., Tretiakov, M. V., Rud, R. O. et al. (2011). Stainless steel corrosion in conditions simulating WWER-1000 primary. Coolant. Corrosion behaviour in mixed core. Pytannia atomnoi nauky i tekhniky. Seriia “Fizyka radiatsiinykh poshkodzhen i radiatsiine materialoznavstvo (97)”, 2 (80), 80–87. Available at: https://vant.kipt.kharkov.ua/ARTICLE/VANT_2011_2/article_2011_2_80.pdf

- Semerak, M. M., Lys, S. S., Yurasova, O. H. (2018). Analysis of the main means of ensuring the water chemistry conditions of the nuclear power plant. Scientific Bulletin of UNFU, 28 (6), 81–83. https://doi.org/10.15421/40280615

- Krasnorutckii, V. S., Petelguzov, І. A., Gritcina, V. M., Zuiok, V. A., Tret′iakov, M. V., Rud, R. O. et al. (2014). Influence on corrosion of stainless steels and zirconium alloys of zinc injection into primary coolant of WWER-1000 reactors. Voprosy atomnoi nauki i tekhniki, 2, 53–61. Available at: http://dspace.nbuv.gov.ua/handle/123456789/79958

- Matkovskyi, O. I. (2023). Mahnetyt. Entsyklopediia Suchasnoi Ukrainy. Kyiv: NAN Ukrainy, NTSh. Available at: https://esu.com.ua/article-60237

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Igor Kozlov, Vyacheslav Kovalchuk, Denys Stepura, Maksym Lysak, Viacheslav Miliev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.