Research on the mechanism of wood protection with eco-friendly paint and varnish coatings

DOI:

https://doi.org/10.15587/2706-5448.2025.329713Keywords:

protective agents, paint and varnish coating, adhesion, surface treatment, protection efficiencyAbstract

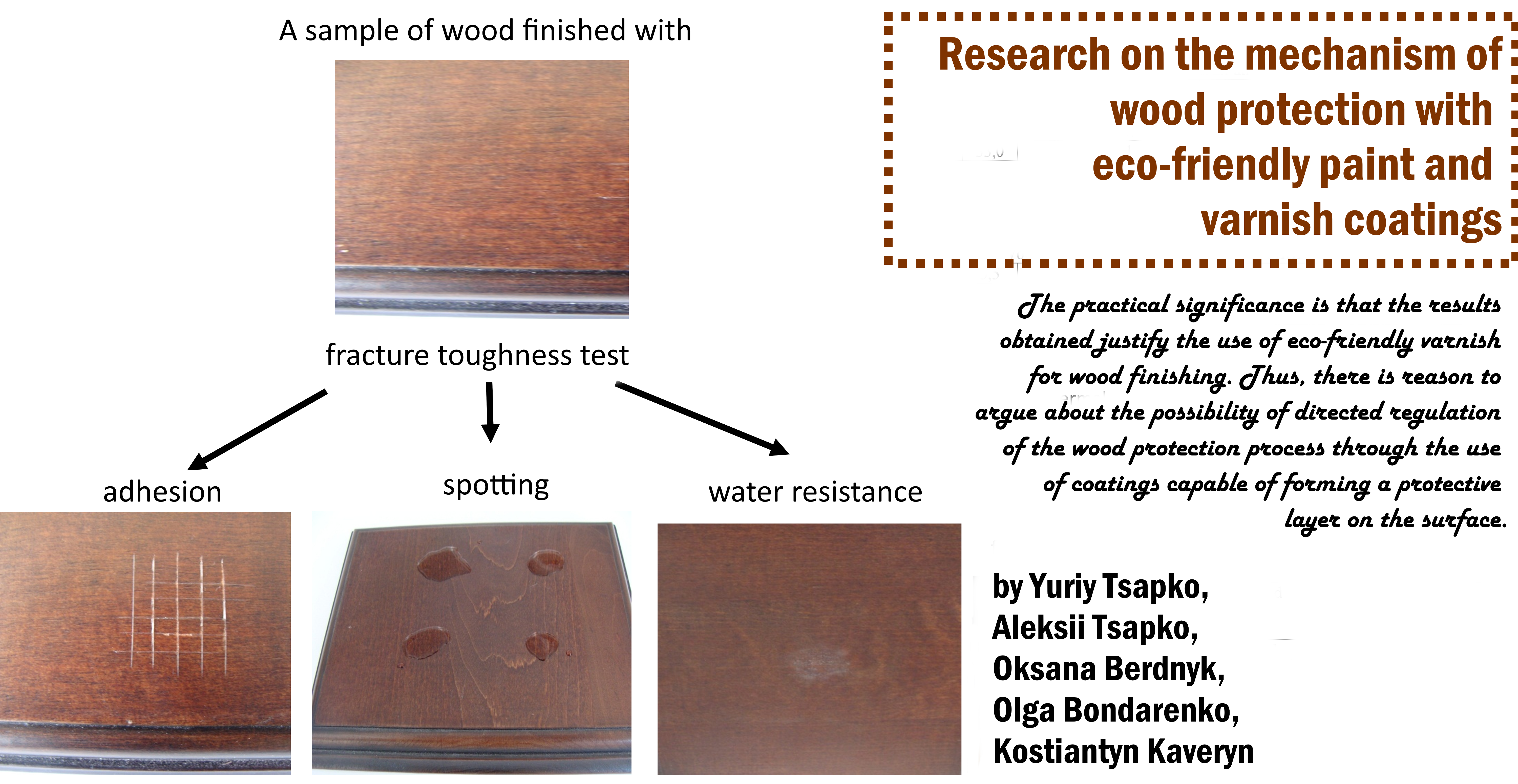

The problem of using wood products is to ensure their protection with a paint and varnish coating in order to increase their durability. Therefore, the object of research was the resistance of the paint and varnish coating when finishing wood to the destruction of adhesion and the action of chemical reagents during operation. It has been proven that for a wood sample finished with nitro-urethane varnish SU-29, when determining adhesion, slight delamination in the form of small scales is observed in the places where the grid lines intersect. However, there are no signs of delamination on a wood sample finished with melamine varnish Plastofix 96 RF. Comparing the samples finished using different technologies, they can be evaluated by points: samples finished with nitro-urethane varnish SU-29 received an adhesion rating of 2 points, namely, slight delamination in the form of small scales in the places where the grid lines intersect. The damage is observed on no more than 5% of the surface of the grid, and the samples finished with Plastofix 96 RF melamine varnish are rated at 1 point – the edges of the cuts are completely smooth, there are no signs of delamination in any square of the grid, i. e. they have better adhesion to wood. The wood surface treated with varnish was assessed for staining, and it was found that the wood surface belongs to 1 point, i. e. there are no visible changes. The results of determining the resistance to water of a wood sample treated with SU-29 nitro-urethane varnish showed a visible trace left by water with a diameter of about 20 mm. In contrast, there are no traces of water on the sample of wood treated with melamine varnish. The practical significance is that the results obtained justify the use of eco-friendly varnish for wood finishing. Thus, there is reason to argue about the possibility of directed regulation of the wood protection process through the use of coatings capable of forming a protective layer on the surface.

References

- Medved, S., Forštnarič, J. (2018). Formaldehyde barrier efficiency of melamine impregnated paper and melamine edge-banding tape surfaced particleboard and MDF. Acta Silvae et Ligni, 116, 43–50. https://doi.org/10.20315/asetl.116.4

- Yan, X., Han, Y., Yin, T. (2021). Coating Process Optimization and Self-Healing Performance Evaluation of Shellac Microcapsules Coated with Melamine/Rice Husk Powder. Applied Sciences, 11 (18), 8373. https://doi.org/10.3390/app11188373

- Basri, E., Martha, R., Damayanti, R., Rahayu, I., Darmawan, W., Gérardin, P. (2022). Durability and wettability of varnishes on the modified and aged surfaces of short rotation teak wood. Pigment & Resin Technology, 53 (4), 464–474. https://doi.org/10.1108/prt-09-2022-0110

- Salas Muñoz, F. B., Sanchez Cespedes, A. M., Guillén Sheen, T. E. (2024). Design of Varnish Based on Dairy Products for Masonry and Wood Walls. Proceedings of the 22nd LACCEI International Multi-Conference for Engineering, Education and Technology (LACCEI 2024): “Sustainable Engineering for a Diverse, Equitable, and Inclusive Future at the Service of Education, Research, and Industry for a Society 5.0”. https://doi.org/10.18687/laccei2024.1.1.252

- Cao, S., Cheng, S., Wang, P., Ge, S., Cai, L., Cai, J. (2023). Construction and characterization of superhydrophobic wood coatings using one-step technique. Colloid and Interface Science Communications, 57, 100757. https://doi.org/10.1016/j.colcom.2023.100757

- Bessike, J. G., Fongnzossie, E. F., Ndiwe, B., Mfomo, J. Z., Pizzi, A., Biwolé, A. B. et al. (2022). Chemical characterization and the effect of a polyherbal varnish coating on the preservation of Ayous wood (Triplochiton scleroxylon). Industrial Crops and Products, 187, 115415. https://doi.org/10.1016/j.indcrop.2022.115415

- Aksu, S., Kelleci, O., Aydemir, D., Istek, A. (2022). Application of acrylic-based varnishes reinforced with nano fillers for conservation of weathered and worn surfaces of the historical and cultural wooden buildings. Journal of Cultural Heritage, 54, 1–11. https://doi.org/10.1016/j.culher.2022.01.003

- Pacheco, C. M., Cecilia, B. A., Reyes, G., Oviedo, C., Fernández-Pérez, A., Elso, M., Rojas, O. J. (2021). Nanocomposite additive of SiO2/TiO2/nanocellulose on waterborne coating formulations for mechanical and aesthetic properties stability on wood. Materials Today Communications, 29, 102990. https://doi.org/10.1016/j.mtcomm.2021.102990

- Zhu, X., Bao, B., Li, Y., Wang, W., Liu, Y. (2020). Effect of thermochromic materials on finishing properties of wood furniture. Journal of Forestry Engineering, 5 (2), 171–178.

- Šimůnková, K., Pánek, M., Zeidler, A. (2018). Comparison of Selected Properties of Shellac Varnish for Restoration and Polyurethane Varnish for Reconstruction of Historical Artefacts. Coatings, 8 (4), 119. https://doi.org/10.3390/coatings8040119

- Yalcin, M. (2018). Surface glossiness properties of wood impregnated with some plant extracts. Forestist, 68 (1), 61–69. https://doi.org/10.5152/forestist.2018.007

- Yoo, Y., Youngblood, J. P. (2017). Tung Oil Wood Finishes with Improved Weathering, Durability, and Scratch Performance by Addition of Cellulose Nanocrystals. ACS Applied Materials & Interfaces, 9 (29), 24936–24946. https://doi.org/10.1021/acsami.7b04931

- DSTU EN ISO 2409:2022. Farby ta laky. Vyprobuvannia metodom reshitchastykh nadriziv (EN ISO 2409:2020, IDT; ISO 2409:2020, IDT) (2022). Kyiv: DP “UkrNDNTs”.

- DSTU EN 335-1:2010. Stiikist derevyny ta vyrobiv z derevyny. Vyznachennia klasiv vykorystannia. Chastyna 1. Zahalni polozhennia (EN 335-1:2006, IDT) (2016). Kyiv: DP “UkrNDNTs”.

- Mazurchuk, S., Marchenko, N., Tsapko, Y., Bondarenko, O., Buyskikh, N., Andor, T., Forosz, V. (2021). Ways to increase the production efficiency of hardwood blanks. E3S Web of Conferences, 280, 07010. https://doi.org/10.1051/e3sconf/202128007010

- Tsapko, Y., Vasylyshyn, R., Horbachova, O., Bondarenko, O. (2021). Improvement of technology of application of wood as a floor covering. IOP Conference Series: Materials Science and Engineering, 1164 (1), 012084. https://doi.org/10.1088/1757-899x/1164/1/012084

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Yuriy Tsapko, Аleksii Tsapko, Oksana Berdnyk, Olga Bondarenko, Kostiantyn Kaveryn

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.