Determination of the dependence of the physico-mechanical properties of alfalfa seed pods on moisture content

DOI:

https://doi.org/10.15587/2706-5448.2025.331286Keywords:

alfalfa seeds, thermal conductivity, heat capacity, thermal diffusivity, density, convective drying, humidity of the materialAbstract

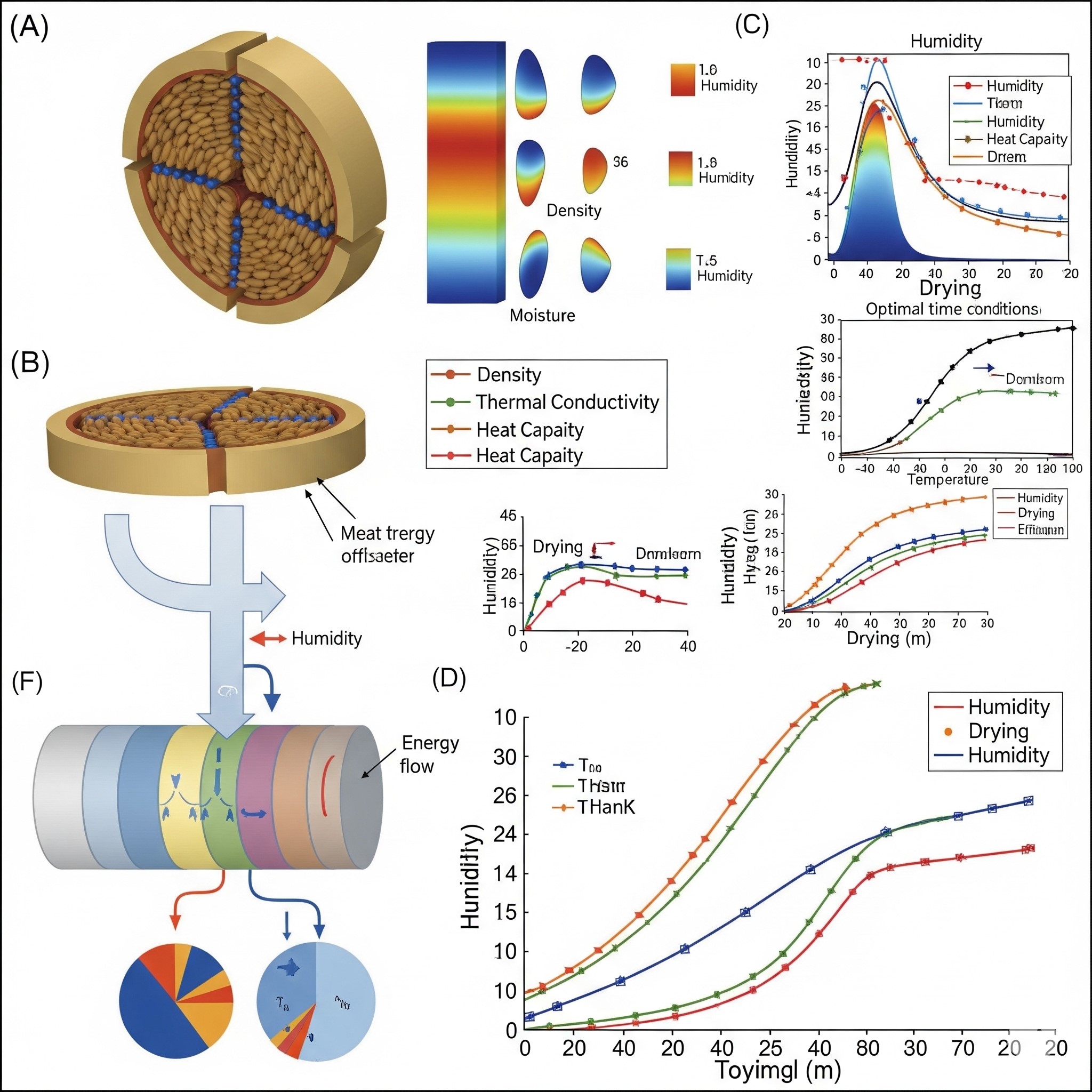

The object of research is the physical, mechanical and thermophysical characteristics of the alfalfa seed crop mixture as factors of the drying process. This issue is of great importance for the energy efficiency of the drying process, as it directly depends on the temperature of the drying agent. Determining the physical, mechanical and thermophysical characteristics of the material will significantly simplify the procedure for determining the maximum permissible temperature of the drying agent. This, in turn, significantly simplifies the procedure for conducting energy and ex-energy analysis of the process.

The study presents the results of experimental investigations focused on determining the thermophysical characteristics of alfalfa seed mass, including heat capacity and thermal conductivity, under varying moisture content. Graphical dependencies illustrate the influence of moisture content on these parameters, demonstrating that the heat capacity and thermal conductivity of alfalfa beans increase as moisture content rises. During the study, standard and original methods were used, which allowed to obtain the dependences of the main physical-mechanical and thermophysical characteristics of the components of the harvest mixture of alfalfa seeds on humidity. In particular, it is determined that the thermal conductivity coefficient of alfalfa beans has a maximum value in the region of 25–30% humidity. This anomaly can be explained by the transition of internal moisture from a free to a bound state.

The research findings contribute to a better understanding of heat and mass transfer mechanisms in biological materials, which is crucial for optimizing drying technologies in agricultural production. The results can be used to improve the efficiency of drying equipment, reduce energy consumption, and enhance the quality of dried alfalfa seeds. The study highlights the importance of selecting appropriate drying parameters to maintain product quality while ensuring energy-efficient processing. The obtained results will allow to significantly simplify and increase the accuracy of determining the rational parameters of the drying process of alfalfa crop mixture. Also, the obtained data will allow to determine the result of the energy and ex-energy drying process much more accurately.

References

- Kontseptsiia rozvytku kormovyrobnytstva v Ukraini na period do 2025 roku (2014). Vinnytsia: Instytut kormiv ta Podillia NAAN, 12.

- Díaz de Otálora, X., Dragoni, F., Del Prado, A., Estellés, F., Wilfart, A., Krol, D., Balaine, L., Anestis, V., Amon, B. (2022). Identification of representative dairy cattle and fodder crop production typologies at regional scale in Europe. Agronomy for Sustainable Development, 42 (5). https://doi.org/10.1007/s13593-022-00830-3

- Kaletnik, H., Yaropud, V., Kupchuk, I., Aliiev, E., Babyn, I., Lavreniuk, P. (2023). Modeling of the technological process of walnut drying in a convective dryer. Przegląd Elektrotechniczny, 1 (12), 93–99. https://doi.org/10.15199/48.2023.12.17

- Olena, S., Mykhailo, Z. (2022). Investigation of the process of drying seeds of herbs. Vibrations in Engineering and Technology, 3 (106), 78–87. https://doi.org/10.37128/2306-8744-2022-3-11

- Paziuk, V., Vyshnevskiy, V., Tokarchuk, O., Kupchuk, I. (2021). Substantiation of the Energy Efficient Schedules of Drying Grain Seeds. Series II: Forestry. Wood Industry. Agricultural Food Engineering, 14 (63 (2)), 137–146. https://doi.org/10.31926/but.fwiafe.2021.14.63.2.13

- Moss, W. M., Guzzomi, A. L., Foster, K. J., Ryan, M. H., Nichols, P. G. H. (2021). Harvesting subterranean clover seed – current practices, technology and issues. Crop and Pasture Science, 72 (3), 223–235. https://doi.org/10.1071/cp20269

- Borisova, M. L., Dianov, L. V. (2015). Ways to reduce losses of seed mass of field crops during combine harvesting. Fod and Agriculture Organization of the United Nations, 31, 85–88.

- Sheychenko, V. O., Anelyak, M. M., Kuzmych, A. Y., Baranovskyi, V. M. (2016). Intensification of the process of collecting seeds of perennial grasses. Technology, Energy, Transport of Agricultural Industry, 94, 29–33.

- Kaletnik, G., Tsurkan, O., Rimar, T., Stanislavchuk, O. (2020). Determination of the kinetics of the process of pumpkin seeds vibrational convective drying. Eastern-European Journal of Enterprise Technologies, 1 (8 (103)), 50–57. https://doi.org/10.15587/1729-4061.2020.195203

- Paziuk, V. M., Petrova, Zh. O., Tokarchuk, O. A., Yaropud, V. M. (2019). Research of rational modes of drying rape seed. INMATEH – agrikultural enginee ring, 58 (2), 303–310. Available at: https://inmateh.eu/volumes/volume-58--no2--2019/58-33-paziuk-research-of-rational-modes-of-drying-rape-seed/

- Solodka, A. V. (2017). Investigation of Heat Exchange in a Fixed of Granular Material. Refrigeration Engineering and Technology, 53 (4), 12–16. https://doi.org/10.15673/ret.v53i4.704

- Bandura, V., Mazur, V., Yaroshenko, L., Rubanenko, O. (2019). Research on sunflower seeds drying process in a monolayer tray vibration dryer based on infrared radiation. INMATEH-Agricultural Engineering, 57 (1), 233–242. Available at: https://www.inma-ita.ro/inmateh/INMATEH_1_2019/57-26-Bandura%20V.pdf

- Sun, X., Guo, Z., Wang, G., Cai, C., Wang, Z. (2023). Hot air drying, impact of infrared drying, and combined hot air-infrared drying on alfalfa drying quality and performance. INMATEH-Agricultural Engineering, 71 (3), 441–450. https://doi.org/10.35633/inmateh-71-38

- Jančík, F., Kubelková, P., Kubát, V., Koukolová, M., Homolka, P. (2017). Effects of drying procedures on chemical composition and nutritive value of alfalfa forage. South African Journal of Animal Science, 47 (1), 96–101. https://doi.org/10.4314/sajas.v47i1.14

- Guo, W., Cheng, S., Cui, Z., He, D., Zhang, X., Shi, T. et al. (2024). Dynamic drying characteristics of alfalfa under solar energy-heat pump combined drying conditions. INMATEH-Agricultural Engineering, 73 (2), 569–580. https://doi.org/10.35633/inmateh-73-48

- Zhilin, A., Fedorov, A., Grebenshchikov, D. (2018). Dynamics of acousto-convective drying of sunflower cake compared with drying by a traditional thermo-convective method. Foods and Raw Materials, 6 (2), 370–378. https://doi.org/10.21603/2308-4057-2018-2-370-378

- Paziuk, V. M., Liubin, M. V., Yaropud, V. M., Tokarchuk, O. A., Tokarchuk, D. M. (2018). Research on the rational regimes of wheat seeds drying. INMATEH-Agricultural Engineering, 56 (3), 39–48. Available at: https://www.inma-ita.ro/inmateh/INMATEH_3_2018/56-05%20Paziuk%20V.M..pdf

- DSTU 4138-2002 Nasinnia silskohospodarskykh kultur. Metody vyznachennia yakosti. Available at: https://fitolab-ck.dpss.gov.ua/wp-content/uploads/2024/01/dstu-4138_2002.pdf

- Bandura, V., Bezbah, I., Kupchuk, I., Fialkovska, L. (2023). Innovative methods of drying rapeseeds using microwave energy. Polityka Energetyczna – Energy Policy Journal, 26 (2), 217–230. https://doi.org/10.33223/epj/163328

- Bandura, V., Yaroshenko, L., Fialkovska, L., Kondratyuk, D., Palamarchuk, V., Paladiichuk, Y. (2021). Case study: dynamics of sunflower seed movement in the vibrating tray of the infrared dryer and its influence on the drying process. Agraarteadus, 32 (2), 204–213. https://doi.org/10.15159/jas.21.24

- Matviienko, S. M. (2019). Improvement of the method for determining the composition of substances by their thermal conductivity. [Author's dissertation Ph.].

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Olena Solona, Anatolii Spirin, Mykhailo Zamrii, Ihor Tverdokhlib, Yurii Polievoda, Kateryna Kovalova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.