Development of a composition for footwear using secondary recycled materials

DOI:

https://doi.org/10.15587/2706-5448.2025.331627Keywords:

chromium-tanned split leather, polymer films, multiparameter optimization, physico-mechanical properties of leatherAbstract

The object of this study is the process of forming a coating on a chromium-tanned split leather semi-finished product. The study is aimed at developing an optimal formulation of a finishing composition for the production of footwear upper leather.

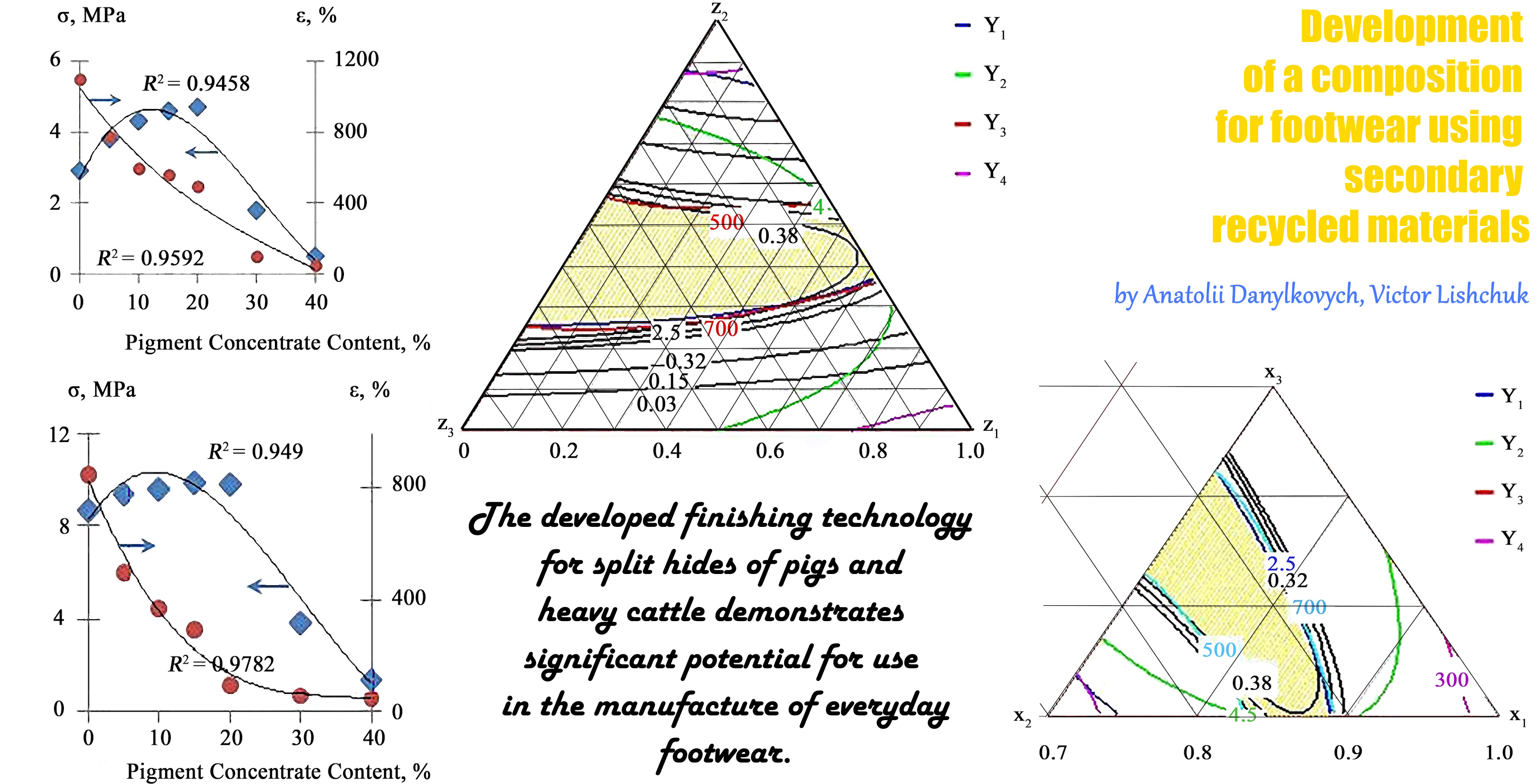

A technology has been developed for forming a decorative coating on chromium-tanned split hides from pigs and heavy cattle. The composition of the finishing formulation was determined through computer modeling and multiparameter optimization using Harrington’s desirability function. Based on the analysis of the physico-mechanical properties of the resulting monolithic films, the qualitative composition of the film-forming finishing composition was established.

Computer-aided modeling of the “composition – property” system for a three-component formulation, using the Scheffé mathematical model, enabled the derivation of analytical relationships between the physico-mechanical properties of the finishing composition and its constituents. The optimal composition was determined at the maximum values of the desirability function and physico-mechanical parameters through multiparameter optimization.

The leather produced using the optimal composition was tested under industrial conditions and complies with DSTU 2726-94 and DSTU 3115-95, for upper footwear leather and leather for garment production, respectively. The use of a highly porous chromium-tanned split leather semi-product derived from pig hides ensures the production of high-quality, elastic upper leather.

The developed finishing technology for split hides of pigs and heavy cattle demonstrates significant potential for use in the manufacture of everyday footwear.

References

- Winter, C., Schultz, M. E. R., Gutterres, M. (2015). Evaluation of polymer resins and films formed by leather finishing. Latin American Applied Research – An International Journal, 45 (4), 213–217. https://doi.org/10.52292/j.laar.2015.400

- Kondratiuk, O. V., Kasian, E. Ye. (2017). Properties of modified polymer compositions for leather finishing. Herald of Khmelnytskyi national university. Technical sciences, 5, 62–66. Available at: http://nbuv.gov.ua/UJRN/Vchnu_tekh_2017_5_14

- Liang, F., Wang, T., Fan, H., Xiang, J., Chen, Y. (2020). A leather coating with self-healing characteristics. Journal of Leather Science and Engineering, 2 (1). https://doi.org/10.1186/s42825-020-0018-4

- Fan, Q., Ma, J., Xu, Q. (2019). Insights into functional polymer-based organic-inorganic nanocomposites as leather finishes. Journal of Leather Science and Engineering, 1 (1). https://doi.org/10.1186/s42825-019-0005-9

- Kondratiuk, O. V., Kasian, E. Ye. (2015). Zastosuvannia preparatu EPAA-2 u pokryvnomu farbuvanni shkirianoho napivfabrykatu. Suchasne materialoznavstvo ta tovaroznavstvo: teoriia, praktyka, osvita. Poltava, 186–189.

- Ivanov, S. V., Trachevskyi, V. V., Hetmanchuk, Yu. P., Mokrynska, O. V., Hrushak, Z. V. (2006). Optymizatsiia skladu polimernoi kompozytsii metodom matematychnoho planuvannia. Visnyk NAU, 4, 199–201.

- Sapronov, O. O. (2014). Optimization of protective coatings for items SPP method of mathematical experiment planning. Naukovyi visnyk Khersonskoi derzhavnoi morskoi akademii, 1, 237–248. Available at: http://nbuv.gov.ua/UJRN/Nvkhdmi_2014_1_34

- Zaiets, A., Andreyeva, O. (2024). Determination of rational parameters of liquid finishing of leather semi-finished product using acrylic polymer and modified fats. Tekstilna Industrija, 72 (3), 11–20. https://doi.org/10.5937/tekstind2403011z

- Hlubish, P. A., Irklei, V. M., Kleiner, Yu. Ya. et al. (2007). Naukove obgruntuvannia, rozroblennia i vprovadzhennia tekhnolohii kompleksnoho bezvidkhodnoho pereroblennia shkirianykh vidkhodiv. Vysokotekhnolohichni, konkurentospromozhni i ekolohichnooriientovani voloknysti materialy ta vyroby z nykh. Kyiv: Aristei, 264.

- Zavada, A. P., Horbachov, A. A. (2005). Osoblyvosti vyrobnytstva shtuchnoi shkiry z vidkhodiv, shcho mistiat kolahen. Suchasni ekolohichno chysti tekhnolohii vyrobnytstva shkiry ta khutra, 54–55.

- Danylkovych, A. H., Vasyliuk, O. V., Olenko, O. M. (2005). Optymizatsiia skladu pihmentnoho kontsentratu z vykorystanniam shkirianoho poroshku. Visnyk KNTEU, 5, 78–87.

- Danylkovych, A. H. (2006). Praktykum z khimii i tekhnolohii shkiry ta khutra. Kyiv: Feniks, 34.

- Cornell, J. A. (2002). Experiments with mixtures: Designs, models, and the analysis of mixture data. New York: Wiley. https://doi.org/10.1002/9781118204221

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Аnatolii Danylkovych, Victor Lishchuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.