Identification of the application features of finishing processing methods of parts with free abrasives at railway rolling stock repair enterprises

DOI:

https://doi.org/10.15587/2706-5448.2025.332016Keywords:

finishing, vibration method, rolling stock, abrasive tool, thin sheet partAbstract

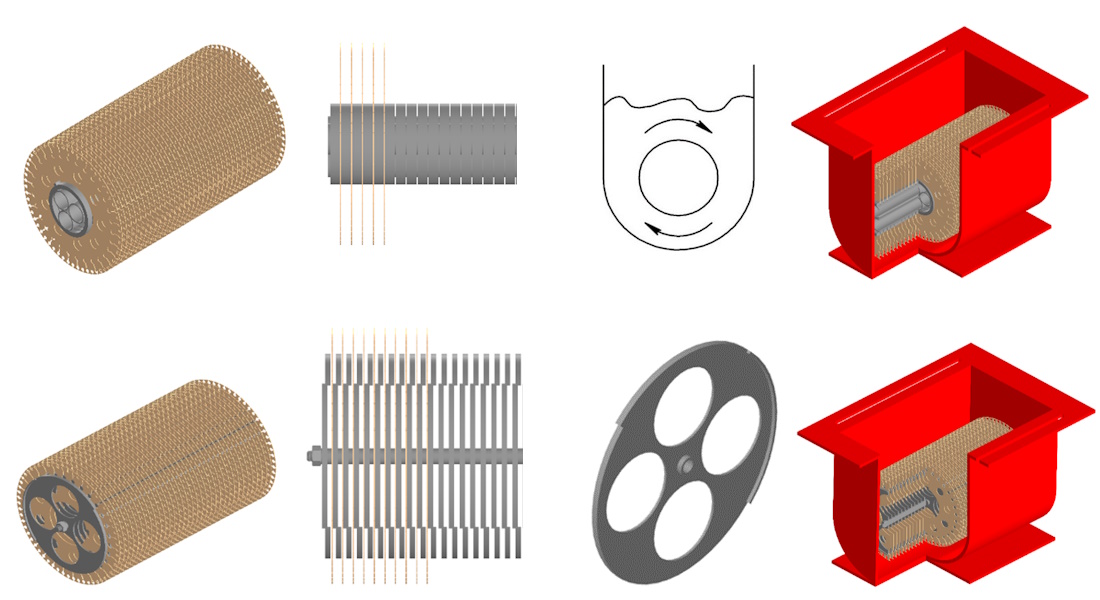

The object of research is the technological process of vibration finishing of the “Rotor Sheet” type flat parts, which are made of thin sheet metal at the enterprises of the railway industry of Ukraine in the process of repairing electric motors of rolling stock. Due to the peculiarities of operation, such parts often have residual defects after laser cutting – burrs, sharp edges, contamination – which negatively affect their further functioning. One of the most problematic areas is ensuring uniform, high-quality processing of a large number of thin parts simultaneously without their deformations and damages. During the study, methods of comparative analysis of technological solutions, experimental testing of vibration processing parameters and selection of the most effective operating modes of the machine were used. A selection of abrasive tools of various shapes and compositions was made and the influence of active alkaline solutions was studied, as well as the design of three structurally different special devices for placing parts in a container. The presented devices ensure positioning of the part with simultaneous access of the abrasive tool to all surfaces being processed. The research results can be used to design processing technologies for various types of flat parts made of thin sheet metal. A rational technological process has been obtained that allows for effective removal of surface defects, improving the quality of processing while maintaining high productivity. This is due to the fact that the proposed approach combines precise selection of processing modes and improved devices, in particular by controlling the movement of parts and optimal distribution of the working environment. This provides the possibility of obtaining high surface quality indicators with a significant reduction in processing time. Compared with similar known methods, this provides improved technological controllability, cost-effectiveness and adaptability to the conditions of mass production in mechanical engineering.

References

- Feng, D., Yang, C., Cui, Z., Li, N., Sun, X., Lin, S. (2020). Research on Optimal Nonperiodic Inspection Strategy for Traction Power Supply Equipment of Urban Rail Transit Considering the Influence of Traction Impact Load. IEEE Transactions on Transportation Electrification, 6 (3), 1312–1325. https://doi.org/10.1109/tte.2020.2999603

- Song, Y., Wang, H., Liu, Z. (2021). An Investigation on the Current Collection Quality of Railway Pantograph-Catenary Systems with Contact Wire Wear Degradations. IEEE Transactions on Instrumentation and Measurement, 70, 1–11. https://doi.org/10.1109/tim.2021.3078530

- Goolak, S., Riabov, Ie., Tkachenko, V., Sapronova, S., Rubanik, I. (2021). Model of pulsating current traction motor taking into consideration magnetic losses in steel. Electrical Engineering & Electromechanics, 6, 11–17. https://doi.org/10.20998/2074-272x.2021.6.02

- Rudniev, Y. S., Romanchenko, J. A., Linevich, A. O. (2022). Study of the dynamics of the movement mechanism of an overhead crane as a complex electromechanical system. Visnik of the Volodymyr Dahl East Ukrainian National University, 5 (275), 35–39. https://doi.org/10.33216/1998-7927-2022-275-5-35-39

- Lee, C.-H., Jwo, J.-S., Hsieh, H.-Y., Lin, C.-S. (2020). An Intelligent System for Grinding Wheel Condition Monitoring Based on Machining Sound and Deep Learning. IEEE Access, 8, 58279–58289. https://doi.org/10.1109/access.2020.2982800

- Aurich, J. C., Herzenstiel, P., Sudermann, H., Magg, T. (2008). High-performance dry grinding using a grinding wheel with a defined grain pattern. CIRP Annals, 57 (1), 357–362. https://doi.org/10.1016/j.cirp.2008.03.093

- Trung, D. D., Nguyen, N.-T., Tien, D. H., Dang, H. L. (2021). A research on multi-objective optimization of the grinding process using segmented grinding wheel by Taguchi-DEAR method. EUREKA: Physics and Engineering, 1, 67–77. https://doi.org/10.21303/2461-4262.2021.001612

- Klocke, F., Barth, S., Mattfeld, P. (2016). High Performance Grinding. Procedia CIRP, 46, 266–271. https://doi.org/10.1016/j.procir.2016.04.067

- Fang, X., Wu, C., Liao, N., Yuan, C., Xie, B., Tong, J. (2022). The first attempt of applying ceramic balls in industrial tumbling mill: A case study. Minerals Engineering, 180, 107504. https://doi.org/10.1016/j.mineng.2022.107504

- Iwasaki, T., Yamanouchi, H. (2020). Ball-impact energy analysis of wet tumbling mill using a modified discrete element method considering the velocity dependence of friction coefficient. Chemical Engineering Research and Design, 163, 241–247. https://doi.org/10.1016/j.cherd.2020.09.005

- Tshimanga, N. L., Combrink, G. A., Wa Kalenga, M. (2021). Surface morphology characterization of grade 304L stainless steel after abrasive blasting. Materials Today: Proceedings, 38, 544–548. https://doi.org/10.1016/j.matpr.2020.02.397

- Jerman, M., Zeleňák, M., Lebar, A., Foldyna, V., Foldyna, J., Valentinčič, J. (2021). Observation of cryogenically cooled ice particles inside the high-speed water jet. Journal of Materials Processing Technology, 289, 116947. https://doi.org/10.1016/j.jmatprotec.2020.116947

- Miturska-Barańska, I., Rudawska, A., Doluk, E. (2021). The Influence of Sandblasting Process Parameters of Aerospace Aluminium Alloy Sheets on Adhesive Joints Strength. Materials, 14 (21), 6626. https://doi.org/10.3390/ma14216626

- Kundrák, J., Mitsyk, A. V., Fedorovich, V. A., Morgan, M., Markopoulos, A. P. (2019). The Use of the Kinetic Theory of Gases to Simulate the Physical Situations on the Surface of Autonomously Moving Parts During Multi-Energy Vibration Processing. Materials, 12 (19), 3054. https://doi.org/10.3390/ma12193054

- Romanchenko, O. (2022). Principles of design of specialized technological equipment. Diagnostyka, 23 (1). https://doi.org/10.29354/diag/146784

- Romanchenko, O., Shumakova, T., Nikolaienko, A., Lohunov, O. (2024). How Geometry Influences the Use of an Abrasive Tool in Relation to the Performance of Vibration Processing. Innovations in Mechanical Engineering III. Cham: Springer, 175–186. https://doi.org/10.1007/978-3-031-62684-5_16

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Oleksiy Romanchenko, Viktor Tkachenko, Tetiana Shumakova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.