Development of polymer composite materials for friction elements of conveyor equipment

DOI:

https://doi.org/10.15587/2706-5448.2025.334018Keywords:

screw conveyor, dry friction, composite, graphite-filled polyamide, antifriction film, wearAbstract

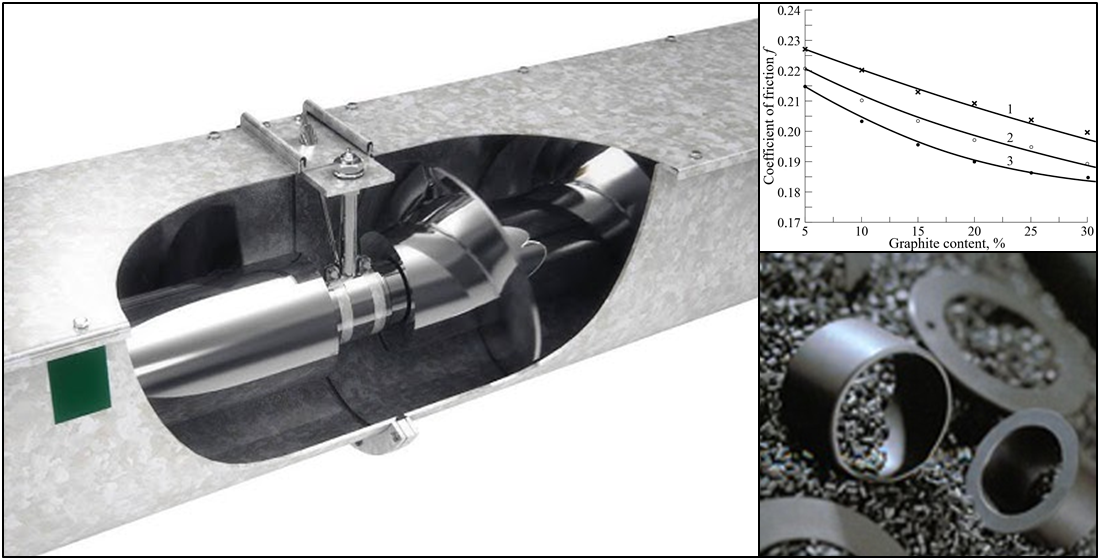

The object of the study is materials with enhanced tribological properties intended for the friction components of conveyor equipment. One of the most critical issues is ensuring the wear resistance of friction units in conveyor systems, particularly under dry friction conditions. A promising solution involves the use of tribotechnical polymer composite materials (PCMs) based on aromatic polyamide.

The research involved the use of modified graphite-containing systems based on aromatic polyamides filled with graphites of various dispersities and at different mass concentrations.

Polymer composites were obtained based on aromatic polyamide modified with organosilicon fluid and filled with graphites differing in nature and morphology. A correlation was established between the antifriction properties of the polymer compositions and both the filler content and graphite grade.

Under dry friction conditions, the enhancement of antifriction properties is achieved by incorporating graphite into the aromatic polyamide in an effective concentration of 15–20%, at which a stable antifriction film forms on the counterbody surface, acting as a solid lubricant. In this case, the coefficient of friction and the linear wear rate of the material remain low, 0.1 to 0.15 and 0.5 to 1 × 10⁻⁹ m/m, respectively. A notable observation is that during friction, the graphite material wears away while the metal remains virtually unaffected. It was found that an excessive filler content (> 20%) leads to brittleness of the composite, which is a critical design limitation.

As a result, the developed material can be effectively used for friction components operating under dry, lubrication-free conditions. This justifies its high utility and environmental benefits, as it eliminates the need for lubricants and their disposal. Compared to traditional materials such as bronze, the proposed composites offer distinct advantages.

References

- Woodcock, C. R., Mason, J. S. (2012). Screw conveying. Bulk Solids Handling. Dordrecht: Springer, 335–357. https://doi.org/10.1007/978-94-009-2635-6_10

- McGlinchey, D. (Ed.) (2008). Bulk Solids Handling. Wiley-Blackwell, 304. https://doi.org/10.1002/9781444305449

- Zapletnikov, I. M., Myronchuk, V. H., Kudriavtsev, V. M. (2020). Ekspluatatsiia i obsluhovuvannia tekhnolohichnoho obladnannia kharchovykh vyrobnytstv. Kyiv: Tsentr uchbovoi literatury, 344.

- Dykha, O. V. (2013). Rozrakhunky vuzliv tertia mashyn. Khmelnytskyi: KhNU, 175.

- Avanesiantc, A. G. (2010). Transportiruiushchie mashiny nepreryvnogo deistviia. Odesa, 177.

- Trigo‐López, M., García, J. M., Ruiz, J. A. R., García, F. C., Ferrer, R. (2018). Aromatic Polyamides. Encyclopedia of Polymer Science and Technology. New Jersey: John Wiley & Sons, Inc., 1–51. https://doi.org/10.1002/0471440264.pst249.pub2

- Kabat, O., Sytar, V., Derkach, O., Sukhyy, K. (2021). Polymeric Composite Materials of Tribotechnical Purpose with a High Level of Physical, Mechanical and Thermal Properties. Chemistry & Chemical Technology, 15 (4), 543–550. https://doi.org/10.23939/chcht15.04.543

- Kabat, O., Bannyk, N., Voronyi, O. (2025). Polymer Composite Materials of Special Purpose for the Aerospace and Rocket Industry. Science and Innovation, 21 (1), 95–103. https://doi.org/10.15407/scine21.01.095

- Aulin, V., Rogovskii, I., Lyashuk, O., Tykhyi, A., Kuzyk, A., Dvornyk, A. et al. (2024). Revealing patterns of change in the tribological efficiency of composite materials for machine parts based on phenylone and polyamide reinforced with arimide-t and fullerene. Eastern-European Journal of Enterprise Technologies, 3 (12 (129)), 6–18. https://doi.org/10.15587/1729-4061.2024.304719

- Kabat, O., Girin, O., Heti, K. (2023). Polymer composites based on aromatic polyamide and fillers of spherical and layered structure for friction units of high-performance equipment. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 237 (11), 2269–2276. https://doi.org/10.1177/14644207231176796

- Kurta, S. A. (2012). Napovniuvachi – syntez, vlastyvosti ta vykorystannia. Ivano‑Frankivsk: Vydavnytstvo Prykarpatskoho natsionalnoho universytetu imeni Vasylia Stefanyka, 302.

- Kim, Y.-H., Kumar, S., Li, X., Kim, S.-Y., Shin, D.-H. (2025). Temperature-dependent mechanical properties and material modifications of carbon fiber composites for optimized structures in high-end industrial applications. Composites Part B: Engineering, 303, 112602. https://doi.org/10.1016/j.compositesb.2025.112602

- Shan, Z., Jia, X., Wang, D., Yang, J., Wang, Z., Song, H. (2025). Nanocellulose domain-limit fluorinated graphite to achieve efficient lubrication of engineered steel surfaces. Sustainable Materials and Technologies, 45. https://doi.org/10.1016/j.susmat.2025.e01445

- Yu, S., Zhu, C., Wu, H., Yao, L., Mahapatra, M., Xu, Y. (2025). Graphite-Enhanced PTFE/PEEK composite coating for improved friction and wear resistance. Applied Surface Science, 700. https://doi.org/10.1016/j.apsusc.2025.163214

- Gong, L., Wu, H., Wang, X., Li, L., Zhang, H., Zeng, S. et al. (2025). Friction and wear properties of graphite/SiC composites built by SLS. Tribology International, 206. https://doi.org/10.1016/j.triboint.2025.110589

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Volodymyr Sytar, Dmytro Kozyrko, Oleh Kabat, Andriy Nazarenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.