Modeling the rheology of commercial reactive fire-retardant coating materials for steel

DOI:

https://doi.org/10.15587/2706-5448.2025.334121Keywords:

fire protection of steel, fire-retardant coating, dynamic viscosity of paint, rheological profile, coating thicknessAbstract

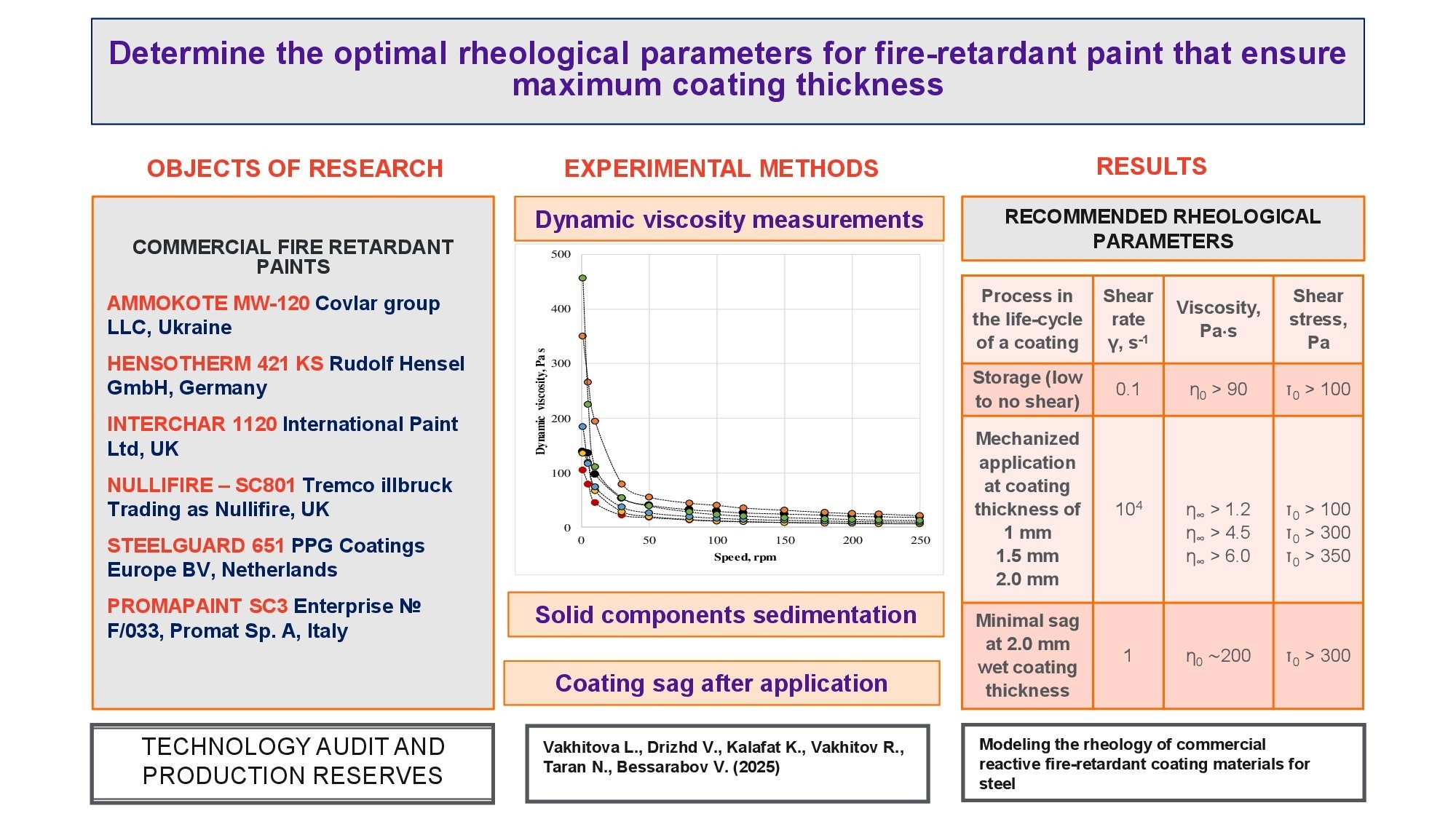

Fire protection of steel load-bearing building structures by surface-treating them with reactive fire-retardant coating materials is a crucial factor in ensuring fire safety on national scale. Both, the quality and operational characteristics of such materials, which are the subject of this study, require continuous improvement to reduce the cost of fire protection, as it can constitute a large portion of the overall construction expenditure. The aim of this study was to determine optimal rheological parameters for commercial reactive fire-retardant coating materials that ensure that the material can be applied with the maximum wet coating thickness.

To achieve this aim, the dynamic viscosity (η) was measured using Brookfield viscometer for a set of commercial reactive fire-retardant coating materials that provide fire resistance of at least R120 for steel load-bearing structures. The dependence of viscosity on shear rate (γ) in the range of (2.09–52.25) s–1 was modeled using the Casson equation. This allowed for the determination of the main rheological parameters of the studied materials – shear stress (τ, Pa), yield stress (τ0, Pa), and viscosity at high shear rates (η∞, Pa · s), which contribute to material’s applicability.

With the use of the empirical and calculational data, the approximate viscosity of water-based intumescent coating materials necessary to produce defect-free layer of wet coating on studied surfaces was determined. It was measured by Brookfield viscometer with No. 7 spindle at rotational speeds (30–50) rpm at 20°С, and should preferably be: (30–15) Pa · s, (at 1 mm wet coating thickness); (50–25) Pa · s, (at 1.5 mm wet coating thickness), (80–50) Pa · s, (at 2.0 mm wet coating thickness). These levels of viscosity prevent sedimentation and sagging of the coating during material’s application and can serve as reference markers for optimization of industrially manufactured intumescent fire-retardant products.

The obtained results can serve as practical recommendations for manufacturers seeking to improve the rheology of reactive fire-retardant materials in order to increase the wet coating thickness per layer.

Supporting Agency

- Budget financing of the NAS of Ukraine.

References

- Nazrun, T., Hassan, M. K., Hasnat, M. R., Hossain, M. D., Ahmed, B., Saha, S. (2025). A Comprehensive Review on Intumescent Coatings: Formulation, Manufacturing Methods, Research Development, and Issues. Fire, 8 (4), 155. https://doi.org/10.3390/fire8040155

- Li, Y., Cao, C.-F., Chen, Z.-Y., Liu, S.-C., Bae, J., Tang, L.-C. (2024). Waterborne Intumescent Fire-Retardant Polymer Composite Coatings: A Review. Polymers, 16 (16), 2353. https://doi.org/10.3390/polym16162353

- Wang, K., Le, H. (2023). The Development of Cement-Based, Intumescent and Geopolymer Fire-Retardation Coatings for Metal Structures: A Review. Coatings, 13 (3), 495. https://doi.org/10.3390/coatings13030495

- Fire-resistant coatings market (2022). Research and Markets, 480. Available at: https://www.researchandmarkets.com/reports/5211858/fire-resistant-coatings-market-by-type

- Vakhitova, L., Kalafat, K., Vakhitov, R., Drizhd, V. (2024). Improving the fire-retardant performance of industrial reactive coatings for steel building structures. Heliyon, 10 (14), e34729. https://doi.org/10.1016/j.heliyon.2024.e34729

- Mohd Sabee, M. M. S., Itam, Z., Beddu, S., Zahari, N. M., Mohd Kamal, N. L., Mohamad, D. et al. (2022). Flame Retardant Coatings: Additives, Binders, and Fillers. Polymers, 14 (14), 2911. https://doi.org/10.3390/polym14142911

- Vakhitova, L., Kalafat, K., Vakhitov, R., Drizhd, V., Taran, N., Bessarabov, V. (2023). Nano-clays as rheology modifiers in intumescent coatings for steel building structures. Chemical Engineering Journal Advances, 16, 100544. https://doi.org/10.1016/j.ceja.2023.100544

- Campos, I. D. D., Bernardo, L. F. A. (2020). Architecture and Steel. Reflection and Analysis on the Use of Steel Structures (in Sight) as a Concept in the History of Architecture. Designs, 4 (3), 30. https://doi.org/10.3390/designs4030030

- Leca, M., Cioroianu, L., Cioroianu, G., Damian, G., Costea, C., Matei, A. M. (2007). Aqueous ecological intumescent fire retardant coatings for multifunctional applications. Revue Roumaine de Chimie, 52 (8-9), 745–752. Available at: https://www.researchgate.net/publication/267826833

- Amusan, T. O., Nwaedozie, J. M., Awe, F. E. (2024). Production and Characterization of Fire-Retardant Coating Materials Using Gum Arabic for Cellulose Surfaces. Trends in Applied Sciences Research, 19 (1), 39–50. https://doi.org/10.3923/tasr.2024.39.50

- Fischer, E. K. (1950). Rheological properties of commercial paints. Journal of Colloid Science, 5 (3), 271–281. https://doi.org/10.1016/0095-8522(50)90030-4

- Zheng, S. X., Chen, H. S. (2023). Correlations of rheological methods to coatings’ performance. Progress in Organic Coatings, 177, 107403. https://doi.org/10.1016/j.porgcoat.2022.107403

- Cibangwa, M. K., Ikhu-Omoregbe, D., Nomnqa, M. (2025). Comparative rheological evaluation of associative thickeners in water-based paint: Influence of polymeric binder and thickener concentration. Case Studies in Chemical and Environmental Engineering, 11, 101122. https://doi.org/10.1016/j.cscee.2025.101122

- Hester, R. D., Squire, D. R. (1997). Rheology of waterborne coatings. Journal of Coatings Technology, 69 (1), 109–114. https://doi.org/10.1007/bf02696097

- Briggs, J. L., Steffe, J. F. (1997). Using Brookfield data and the Mitschka method to evaluate power law foods. Journal of Texture Studies, 28 (5), 517–522. https://doi.org/10.1111/j.1745-4603.1997.tb00134.x

- Rheological characterization of paints and coatings. AZoM. Available at: https://www.azom.com/article.aspx?ArticleID=12120

- Holmes, M. H. (2019). Newtonian fluids. Introduction to the foundations of applied mathematics. Cham: Springer, 445–495. https://doi.org/10.1007/978-3-030-24261-9_9

- Richards, J. A., Hodgson, D. J. M., O’Neill, R. E., DeRosa, M. E., Poon, W. C. K. (2024). Optimizing non-Newtonian fluids for impact protection of laminates. Proceedings of the National Academy of Sciences, 121 (10). https://doi.org/10.1073/pnas.2317832121

- Li, Z., Zheng, L., Huang, W. (2020). Rheological analysis of Newtonian and non‐Newtonian fluids using Marsh funnel: Experimental study and computational fluid dynamics modeling. Energy Science & Engineering, 8 (6), 2054–2072. https://doi.org/10.1002/ese3.647

- Jankowska, H., Dzido, A., Krawczyk, P. (2023). Determination of Rheological Parameters of Non-Newtonian Fluids on an Example of Biogas Plant Substrates. Energies, 16 (3), 1128. https://doi.org/10.3390/en16031128

- Rafiq, S., Bilal, B. A., Afzal, A., Tawade, J. V., Kulkarni, N. V., Abdullaeva, B. et al. (2025). Thermo-fluid dynamics of non-newtonian casson fluid in expanding-contracting channels with joule heating and variable thermal properties. Partial Differential Equations in Applied Mathematics, 13, 101105. https://doi.org/10.1016/j.padiff.2025.101105

- Shahzad, H., Wang, X., Ghaffari, A., Iqbal, K., Hafeez, M. B., Krawczuk, M. et al. (2022). Fluid structure interaction study of non-Newtonian Casson fluid in a bifurcated channel having stenosis with elastic walls. Scientific Reports, 12 (1). https://doi.org/10.1038/s41598-022-16213-3

- Abraham, J., Sharika, T., George, S. C., Thomas, S. (2017). Rheological percolation in thermoplastic polymer nanocomposites. Rheology: Open Access, 1, 102.

- Pipe, C. J., Majmudar, T. S., McKinley, G. H. (2008). High shear rate viscometry. Rheologica Acta, 47 (5-6), 621–642. https://doi.org/10.1007/s00397-008-0268-1

- Afoakwa, E. O., Paterson, A., Fowler, M., Vieira, J. (2008). Comparison of rheological models for determining dark chocolate viscosity. International Journal of Food Science & Technology, 44 (1), 162–167. https://doi.org/10.1111/j.1365-2621.2008.01710.x

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Liubov Vakhitova, Varvara Drizhd, Kostyantyn Kalafat, Ramil Vakhitov, Nadiia Taran, Volodymyr Bessarabov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.