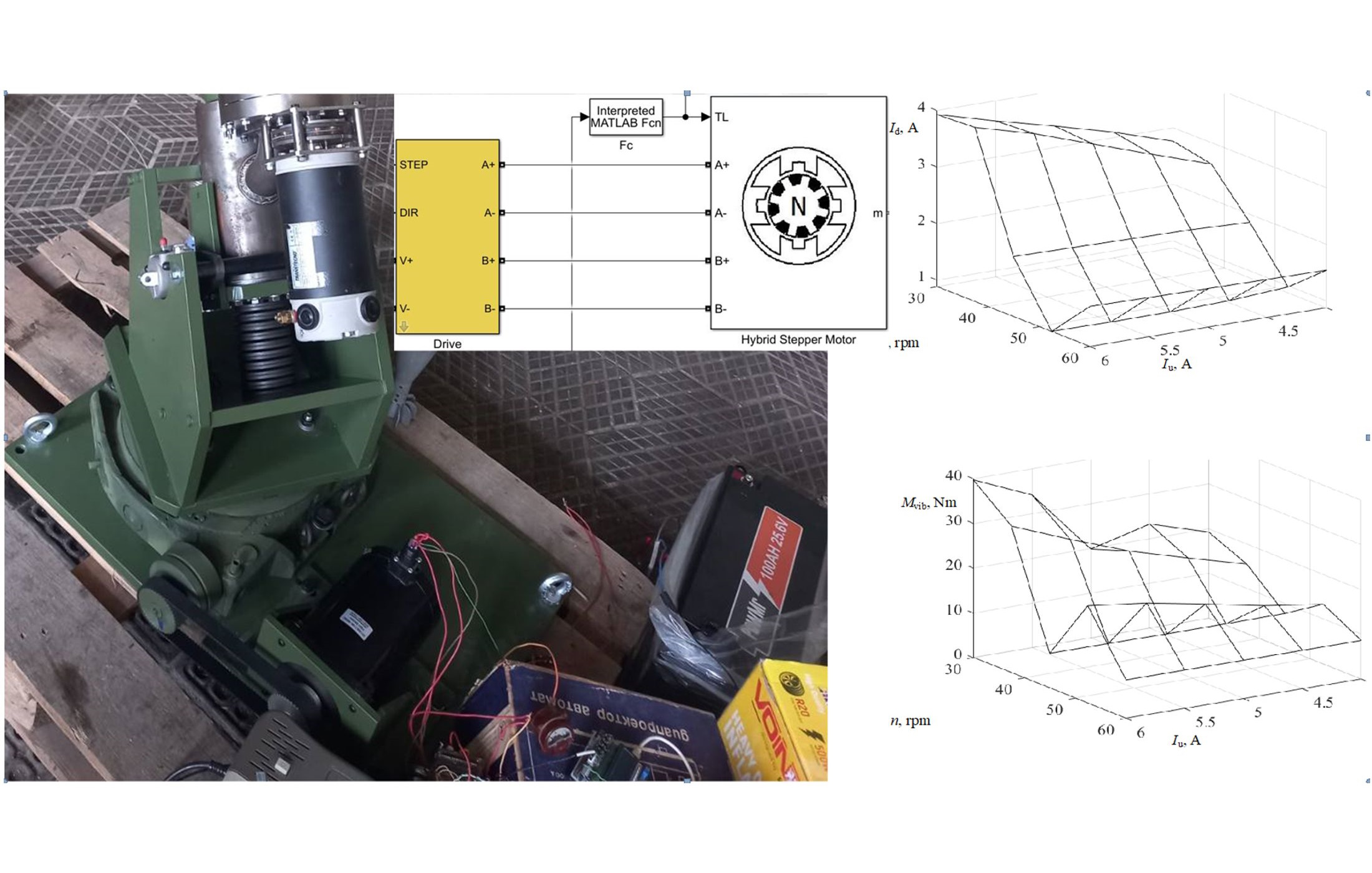

Determination of the influence of the control parameters of the stepper drive for rotating the platform for a gas-detonation mortar on its electrical and mechanical performance

DOI:

https://doi.org/10.15587/2706-5448.2025.339377Keywords:

stepper motor, platform, gas-detonation mortar, setpoint current, vibration torqueAbstract

The object of research is the processes of platform rotation during the operation of the stepper drive of a gas-detonation powderless mortar. The problem solved by the study is to determine the influence of the set current and the rotation frequency of the stepper motor for the rotation of the platform for a gas-detonation mortar on the effective value of the phase current, vibration and maximum engine torques. According to the results of the research, it was determined that the effective value of the phase current has a variable character. The minimum value of the effective phase current is observed at a rotation frequency of 52.5 rpm, and a set current of 5.5 A, and is 0.875 A. The obtained dependence of the effective current on the control parameters has a non-monotonic variable character, due to a change in the shape of the current during engine operation, which, in turn, significantly changes the harmonic composition of the current. The dependence of the vibration torque of the engine also has a variable character. However, the minimum vibration is observed at a rotation frequency of 45 rpm, and a set current of 5 A, and is 7.715 N ⋅ m, and the maximum vibrations at the minimum operating frequency and the maximum setpoint current reach 39.72 N ⋅ m. The dependence of the maximum torque value on the stepper motor shaft has a decreasing character, due to the operation of the drive in the starting mode. The decrease in the starting torque is due, on the one hand, to a decrease in the setpoint current, and, accordingly, to the maximum motor current and an increase in the electromotive force in phase with an increase in the setpoint speed. The obtained research results can be used in practice when creating an automated electric drive for turning a gas-detonation mortar based on a stepper motor by selecting the parameters of the setpoint current for the semiconductor converter, in accordance with the rotation speed. The conducted research can be used as the basis for the methodology for determining the control parameters of the electric drive for turning based on a stepper motor.

Supporting Agency

- The work was carried out with the financial support of the National Research Foundation of Ukraine. Project registration number: 2023.04/0101 “Design of the automated aiming and control systems of the gas-detonation mortar for firing smoke grenades”.

References

- Sakun, O. V. (2018). Istoriia ta perspektyvy zastosuvannia tankovykh minometiv. Mekhanika ta mashynobuduvannia, 1, 89–96. Available at: https://www.ukrmilitary.com/2018/09/tank-mortar.html

- Merkava 4. Army Recognition. Available at: https://www.armyrecognition.com/military-products/army/main-battle-tanks/main-battle-tanks/merkava-iv-4-israel-uk

- Streetfighter and the future of the Challenger 2. Army Technology. Available at: https://www.army-technology.com/features/streetfighter-challenger-2/?cf-view

- Lye, H. (2020). British Army demos new Challenger 2 urban operation tank concept. Shephard Media. Available at: https://www.shephardmedia.com/news/landwarfareintl/british-army-demos-new-challenger-2-urban-operatio/

- Senderowski, C., Panas, A. J., Fikus, B., Zasada, D., Kopec, M., Korytchenko, K. V. (2021). Effects of Heat and Momentum Gain Differentiation during Gas Detonation Spraying of FeAl Powder Particles into the Water. Materials, 14 (23), 7443. https://doi.org/10.3390/ma14237443

- Liubarskyi, B., Kryvosheiev, S., Eresko, O., Galitsa, V., Poliakov, I., Liubarskyi, D. (2024). Determination of effort in an energy-efficient system of electromagnetic charge holding. Bulletin of the National Technical University “KhPI”. Series: Energy: Reliability and Energy Efficiency, 2 (9), 25–30. https://doi.org/10.20998/eree.2024.2(9).316265

- Kenjo, T., Sugawara, A. (1995). Stepping motors and their microprocessor controls. Oxford University Press. https://doi.org/10.1093/oso/9780198593867.001.0001

- Acarnley, P. (2002). Stepping Motors: a guide to theory and practice. Institution of Engineering and Technology. https://doi.org/10.1049/pbce063e

- Zhang, D., Wang, J., Qian, L., Yi, J. (2019). Stepper motor open-loop control system modeling and control strategy optimization. Archives of Electrical Engineering, 68 (1), 63–75. https://doi.org/10.24425/aee.2019.125980

- Wang, L., Xin, X., Zhu, L. (2016). A widely tunable fiber ring laser with closed loop control based on high-precision stepper motor. Optoelectronics Letters, 12 (3), 169–172. https://doi.org/10.1007/s11801-016-6033-2

- Dorin-Mirel, S., Lita, I., Oproescu, M. (2017). Comparative analysis of stepper motors in open loop and closed loop used in nuclear engineering. 2017 IEEE 23rd International Symposium for Design and Technology in Electronic Packaging (SIITME), 357–360. https://doi.org/10.1109/siitme.2017.8259924

- Liubarskyi, B., Petrenko, О., Iakunin, D., Dubinina, O. (2017). Optimization of thermal modes and cooling systems of the induction traction engines of trams. Eastern-European Journal of Enterprise Technologies, 3 (9 (87)), 59–67. https://doi.org/10.15587/1729-4061.2017.102236

- Goolak, S., Liubarskyi, B., Riabov, I., Chepurna, N., Pohosov, O. (2023). Simulation of a direct torque control system in the presence of winding asymmetry in induction motor. Engineering Research Express, 5 (2), 025070. https://doi.org/10.1088/2631-8695/acde46

- Deng, N., Cao, H. Y., Hu, C. G. (2016). Application of stepper motor subdivision drive in transformation of CA6140 lathe. 2016 IEEE 11th Conference on Industrial Electronics and Applications (ICIEA), 218–219. https://doi.org/10.1109/iciea.2016.7603581

- Kim, W., Shin, D., Lee, Y., Chung, C. C. (2016). Simplified torque modulated microstepping for position control of permanent magnet stepper motors. Mechatronics, 35, 162–172. https://doi.org/10.1016/j.mechatronics.2016.02.002

- Morar, A. (2015). The Modelling and Simulation of Bipolar Hybrid Stepping Motor by Matlab/Simulink. Procedia Technology, 19, 576–583. https://doi.org/10.1016/j.protcy.2015.02.082

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Borys Liubarskyi, Serhii Kryvosheiev, Oleksandr Eresko, Vitalii Halytsia, Oleksandr Sakun, Dmytro Liubarskyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.