Optimization of forces in cutting poultry carcasses with disc knives

DOI:

https://doi.org/10.15587/2706-5448.2025.340896Keywords:

cutting force, poultry carcasses, blade sharpening angle, disc knife, disc rotation speedAbstract

The object of research was the process of cutting poultry carcasses of chickens, ducks, and geese using disc knives. In the food industry, when processing poultry, and especially when disassembling it, which divides the carcasses into certain parts and sizes, carcass cutting operations are widely used. This process significantly affects the level of energy consumption of the entire production and the quality of the finished product. The main working parts of cutting machines are knives, the purpose of which depends on the entire technological process of chopping.

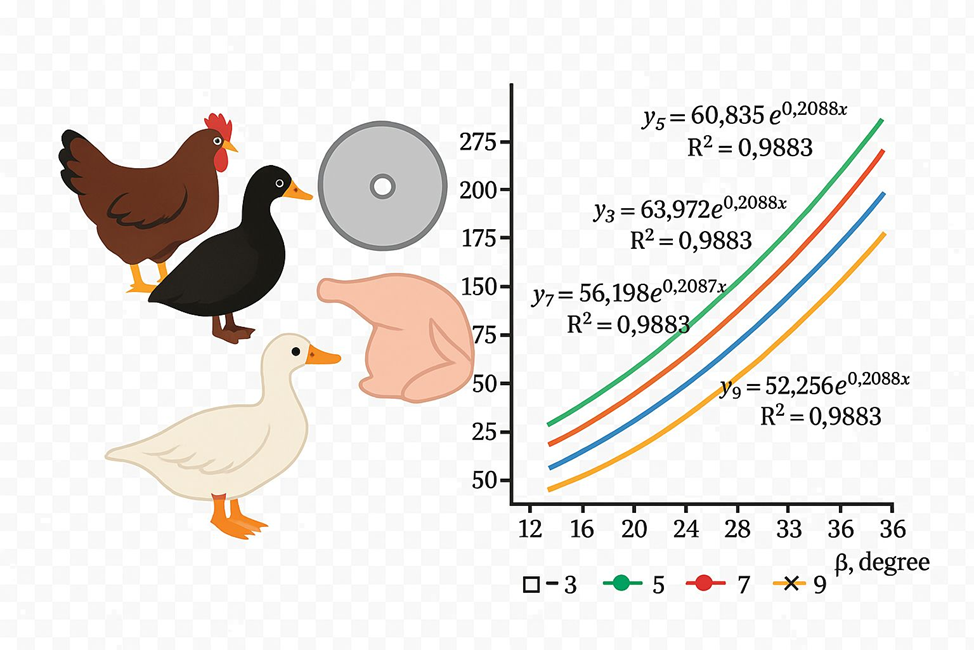

The dependence of the cutting forces of meat with bones of chickens, ducks and geese on the rotation speed of the disk knife and its sharpening angle at different product temperatures was experimentally established. It was established that with an increase in the cutting speed, the cutting force decreases. Approximate relationships were obtained for quantitative description of the influence of cutting speed on cutting force for different types of poultry, which allow to predict the energy consumption of the process. For producers, the range of cutting speed of poultry carcasses by the disk cutting body of the machine can be recommended from 6.5 to 9 m/s. The influence of the blade sharpening angle on the energy intensity of grinding poultry carcasses was studied; a rational range of sharpening angle was determined, at which cutting forces are minimized while maintaining the stability of the tool. Taking into account the structural and mechanical characteristics of poultry carcasses, operational indicators and technological requirements for the quality and cleanliness of the cut surface, the range of sharpening angle of the knife cutting edge is 20–26°. An applied aspect of using the obtained result is the possibility of improving the design parameters of disk knives and will ensure increased equipment productivity and cutting quality. However, the cutting force depends not only on the species and fatness, but also on the age, sex of the bird and the location of the muscles.

References

- Burdo, O. G., Bandura, V. N., Levtrinskaya, Y. O. (2018). Electrotechnologies of Targeted Energy Delivery in the Processing of Food Raw Materials. Surface Engineering and Applied Electrochemistry, 54 (2), 210–218. https://doi.org/10.3103/s1068375518020047

- Nikolaienko, M., Bal-Prylypko, L. (2020). Development of an integrated food quality management system. Potravinarstvo Slovak Journal of Food Sciences, 14, 862–873. https://doi.org/10.5219/1434

- Bal-Prylypko, L., Kanishchev, O., Mushtruk, M., Leonova, B. (2024). Development of technology for extended-shelf-life meat products. Animal Science and Food Technology, 15 (4), 132–149. https://doi.org/10.31548/animal.4.2024.132

- Biazik, E., Kralik, Z., Kosevic, M. (2022). Antioxidants in poultry meat products: quality, safety and health aspects. Żywność. Nauka. Technologia. Jakość, 29 (3), 17–31. https://doi.org/10.15193/zntj/2022/132/420

- Franczyk-Żarów, M., Koronowicz, A., Szymczyk, B., Bieżanowska-Kopeć, R., Leszczyńska, T. (2017). Effect of dietary conjugated linoleic acid (CLA) and thermal processing on fatty acid composition of enriched chicken meat. Journal of Animal and Feed Sciences, 26 (3), 236–246. https://doi.org/10.22358/jafs/76184/2017

- Baéza, E., Guillier, L., Petracci, M. (2022). Review: Production factors affecting poultry carcass and meat quality attributes. Animal, 16, 100331. https://doi.org/10.1016/j.animal.2021.100331

- Lynch, S. A., Mullen, A. M., O’Neill, E., Drummond, L., Álvarez, C. (2018). Opportunities and perspectives for utilisation of co-products in the meat industry. Meat Science, 144, 62–73. https://doi.org/10.1016/j.meatsci.2018.06.019

- Bekeshova, G., Ibragimov, N., Kakimov, A., Suychinov, A., Yessimbekov, Z., Kabdylzhar, B. et al. (2022). Effect of Rotational Speed and Gap between Rotating Knives of the Grinder on the Yield Stress and Water-Binding Capacity of Fine Ground Chicken Bone. Applied Sciences, 12 (7), 3533. https://doi.org/10.3390/app12073533

- Bal-Prylypko, L., Yancheva, M., Paska, M., Ryabovol, M., Nikolaenko, M., Israelian, V. et al. (2022). The study of the intensification of technological parameters of the sausage production process. Potravinarstvo Slovak Journal of Food Sciences, 16, 27–41. https://doi.org/10.5219/1712

- Schuldt, S., Schneider, Y., Rohm, H. (2018). High-speed cutting of foods: Cutting behavior and initial cutting forces. Journal of Food Engineering, 230, 55–62. https://doi.org/10.1016/j.jfoodeng.2018.02.024

- Berger, L. M., Witte, F., Tomasevic, I., Heinz, V., Weiss, J., Gibis, M. et al. (2023). A review on the relation between grinding process and quality of ground meat. Meat Science, 205, 109320. https://doi.org/10.1016/j.meatsci.2023.109320

- Marsot, J., Claudon, L., Jacqmin, M. (2007). Assessment of knife sharpness by means of a cutting force measuring system. Applied Ergonomics, 38 (1), 83–89. https://doi.org/10.1016/j.apergo.2005.12.007

- Zieliński, B., Chaciński, T., Pimenov, D. Y., Nadolny, K. (2021). Methodology for Evaluating the Cutting Force of Planar Technical Blades Used in Flatfish Processing. Micromachines, 12 (12), 1516. https://doi.org/10.3390/mi12121516

- Bakiyeva, A., Yerengaliyev, A., Kakimov, A., Zhumadilova, G., Abdilova, G., Serikov, E. et al. (2024). Development of the Design of Plate with Variable Diameters of Holes and Its Impact on Meat-Grinding Quality and Efficiency. Processes, 12 (9), 1808. https://doi.org/10.3390/pr12091808

- Holl, H. J., Meindlhumer, M., Simader, V., Schnürer, D., Brandl, A. (2018). Experimental investigation of friction reduction. Materials Today: Proceedings, 5 (13), 26615–26621. https://doi.org/10.1016/j.matpr.2018.08.125

- Klymenko, M. M., Vinnikova, L. H., Bereza, I. H., Honcharov, H. I., Pasichnyi, V. M., Bal-Prylypko, L. V. et al.; Klymenko, M. M. (Ed.) (2006). Tekhnolohiia miasa ta miasnykh produktiv. Kyiv: Vyshcha osvita, 640. Available at: https://dspace.nuft.edu.ua/items/f42e6d50-6780-40c0-93a5-7de7f9d24981

- McGorry, R. W., Dowd, P. C., Dempsey, P. G. (2003). Cutting moments and grip forces in meat cutting operations and the effect of knife sharpness. Applied Ergonomics, 34 (4), 375–382. https://doi.org/10.1016/s0003-6870(03)00041-3

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Larysa Bal-Prylypko, Valentyna Bandura, Marina Serdyuk, Halyna Shlapak, Nadia Novgorodska, Nadia Zahorko, Iryna Basarab

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.