Determination of the patterns of changes in the quality indicators of crushing corn and sunflower stems by working bodies of technical equipment

DOI:

https://doi.org/10.15587/2706-5448.2025.340915Keywords:

stalk crushing, single and double roll crushers, disc harrow, combined unit, crushing quality indicators, corn and sunflower stalksAbstract

The object of research is the technological processes of crushing plant residues, corn and sunflower stalks, working bodies of single and double roll crushers, disk harrow, as well as combined unit consisting of disk harrow and single roll crusher. The relevance of the research is due to the need to solve the problem of increasing the efficiency of technological crushing operations by intensifying (increasing) the effects of the working bodies of the tools on the plant environment.

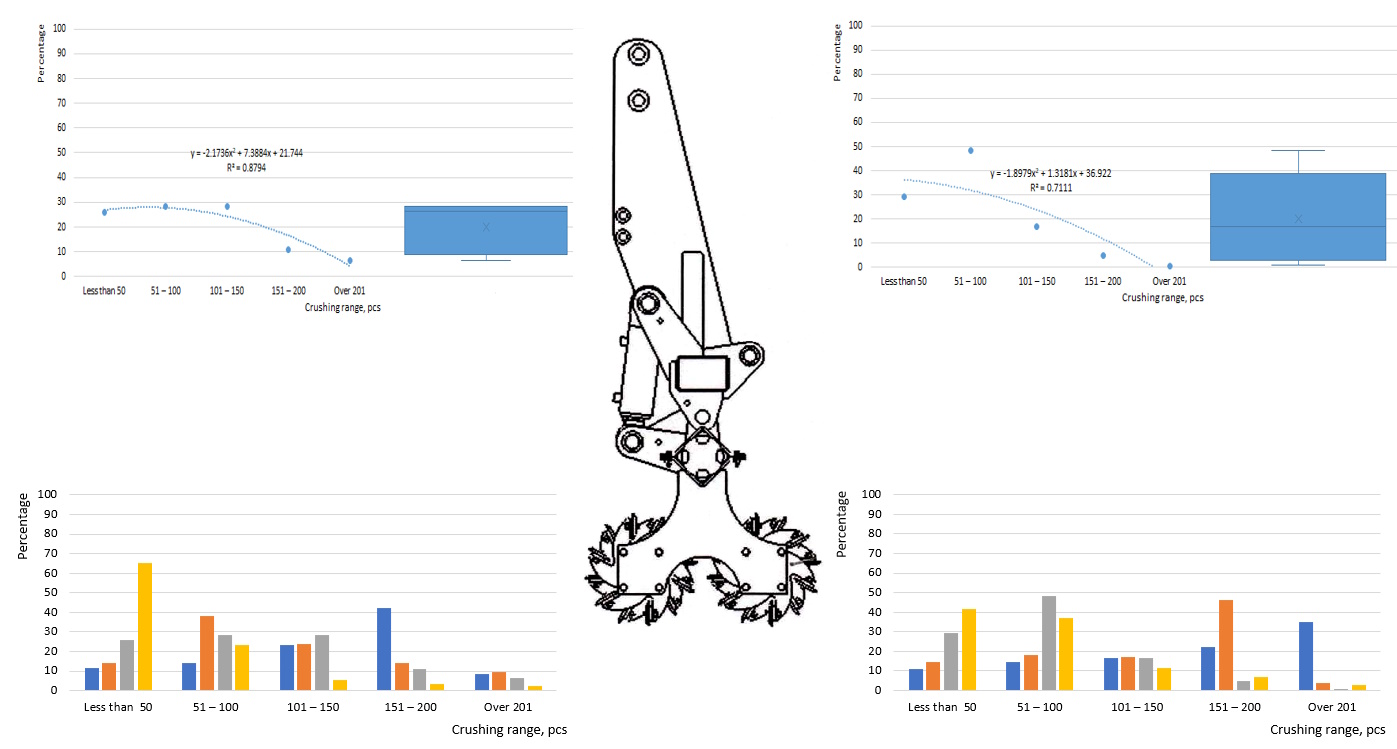

A prototype of double roll crusher was developed and manufactured, the cutting knives of which are placed across the entire width of the grip in a staggered manner with the ability to change the angle of inclination to the axis of rotation of the drum in the range of 6–10°. The highest value of the relative frequencies of corn crushing by double roll crusher belonged to the ranges of 51–100 mm and 101–150 mm, the sum of which was 56% and 52%, respectively. The largest share of 48.25% of crushed sunflower stalks by double roll crusher was established for the range of 51–100 mm. The sum of the percentages of crushed sunflower stalks in the ranges less than 50–100 mm was 77.62%, which is 2.36 times more than the similar indicator of single roll crusher, 3 times more than that of a harrow, and almost coincided with the indicators of a combined unit. In a disk harrow, the largest number of shares of crushed corn stalks 42.2% belonged to the range of 151–200 mm, and sunflower stalks 35.2% to the range over 201 mm. In a combined unit, the largest value of the percentage of crushed stalks was established in the range less than 50 mm. For corn, the specified value was 65.4%, for sunflower 41.5%, respectively. The contribution of single roll crusher to the total percentage of crushed stems in the range of up to 150 mm in a combined unit was 44.7% for corn and 47.7% for sunflower.

The results of the research are recommended for crop growing systems under the conditions of choosing rational technical and technological solutions for crushing plant residues.

References

- Sheichenko, V., Chernovol, M., Volskyi, V., Kotsiubanskyi, R. (2021). Research of Influence of the Scheme of an Arrangement of Knives of a Cat-shredder on Indicators of Quality of Crushing of Stalks of Sunflower. National Interagency Scientific and Technical Collection of Works. Design, Production and Exploitation of Agricultural Machines, 51, 78–88. https://doi.org/10.32515/2414-3820.2021.51.78-88

- Sheichenko, V., Volskyi, V., Kotsiubanskyi, R., Dnes, V., Bilovod, O., Shevchuk, M. et al. (2023). Determining the effect of the direction of installing the cutting edges of shredder roller blades on process parameters. Eastern-European Journal of Enterprise Technologies, 5 (1 (125)), 45–53. https://doi.org/10.15587/1729-4061.2023.287483

- Tsyliuryk, Ya. (2019). Poverkhnevyi obrobitok i roslynni reshtky. Zerno. Available at: https://www.zerno-ua.com/journals/2019/may-2019-god/poverhneviy-obrobitok-i-roslinni-reshtki

- Sheichenko, V., Volskyi, V., Dnes, V., Kotsiubanskyi, R. (2022). Study of grinding corn stalks by a roller grinder with different knives positioning. Mechanization in Agriculture and Conserving of the Resources, 66 (2), 52–55. Available at: https://www.agrimachinery.net/sbornik/2022.pdf

- Salo, V., Bohatyrov, D., Leshchenko, S. (2023). Regarding the Reliability of the Technological Process of Shredding Crop Residues. National Interagency Scientific and Technical Collection of Works. Design, Production and Exploitation of Agricultural Machines, 53, 93–101. https://doi.org/10.32515/2414-3820.2023.53.93-101

- Sheichenko, V., Volskyi, V., Kotsiubanskyi, R., Dnes, V., Shevchuk, M., Bilovod, O. et al. (2021). Design of a roll crusher for sunflower stems and substantiation of the rational modes of its operation. Eastern-European Journal of Enterprise Technologies, 6 (1 (114)), 28–37. https://doi.org/10.15587/1729-4061.2021.244903

- Bohatyrov, D. V., Salo, V. M., Kyslun, O. A., Skrynnik, I. O., Kisilov, R. V. (2017). Influence of equal-area projection of the cylinder drum's cross-section height on the description accuracy of its overcoming the air resistance force. INMATEH – Agricultural Engineering, 52 (2), 7–12. Available at: https://dspace.dsau.dp.ua/bitstream/123456789/413/1/6.pdf#page=65

- Kornecki, T. S., Prior, S. A. (2017). Equipment development to manage cover crops for small and urban no-till farming systems. Chemical Engineering Transactions, 58, 181–186. https://doi.org/10.3303/CET1758031

- Voitiuk, D. H., Baranovskyi, V. M., Bulhakov, V. M.; Voitiuk, D. H. (Ed.) (2005). Silskohospodarski mashyny. Osnovy teorii ta rozrakhunku. Kyiv: Vyshcha osvita, 464. Available at: https://vpu36balin.km.ua/wp-content/uploads/2025/04/Сільськогосподарські-машини.-Основи-теорії-та-роз-.pdf

- Kornecki, T. S., Price, A. J., Raper, R. L. (2006). Performance of different roller designs in terminating rye cover crop and reducing vibration. Applied Engineering in Agriculture, 22 (5), 633–641. https://doi.org/10.13031/2013.21994

- Yu, Y., Li, Y., Xie, F., Tian, Y. (2024). Experimental study on the performance of corn stalk crushing device with stepped saw disk knife. INMATEH Agricultural Engineering, 535–542. https://doi.org/10.35633/inmateh-74-47

- Behera, A., Raheman, H., Thomas, E. V. (2021). A comparative study on tillage performance of rota-cultivator (a passive – active combination tillage implement) with rotavator (an active tillage implement). Soil and Tillage Research, 207, 104861. https://doi.org/10.1016/j.still.2020.104861

- Büchi, L., Wendling, M., Amossé, C., Jeangros, B., Charles, R. (2020). Cover crops to secure weed control strategies in a maize crop with reduced tillage. Field Crops Research, 247, 107583. https://doi.org/10.1016/j.fcr.2019.107583

- Gürsoy, S., Türk, Z. (2019). Effects of land rolling on soil properties and plant growth in chickpea production. Soil and Tillage Research, 195, 104425. https://doi.org/10.1016/j.still.2019.104425

- Michkivskyi, S., Baldyk, D., Holovan, V. (2023). Microsoft Office (Word, Excel, Outlook …). Kyiv: Vydavnytstvo Skhidnoukrainskoho natsionalnoho universytetu imeni Volodymyra Dalia, 128. Available at: https://dspace.snu.edu.ua/server/api/core/bitstreams/5663399d-ba62-4368-b7b6-1aab8356e838/content

- Calcante, A., Manenti, D., Torrente, M. D. M., Oberti, R. (2024). Comparison of the Effectiveness of Different Mechanical Tools for the Termination of Cover Crops Using a Modular Prototype. Applied Engineering in Agriculture, 40 (2), 211–223. https://doi.org/10.13031/aea.15714

- Ji, H., Liu, G., Liu, W., Yang, Y., Guo, X., Zhang, G. et al. (2025). Quantitative design and production methods for sustainably increasing maize grain yield and resource use efficiency. Frontiers of Agricultural Science and Engineering, 12 (3), 465–477. https://doi.org/10.15302/J-FASE-2025601

- Ramm, S., Voßhenrich, H. H., Hasler, M., Reckleben, Y., Hartung, E. (2024). Comparative Analysis of Mechanical In-Field Corn Residue Shredding Methods: Evaluating Particle Size Distribution and Rating of Structural Integrity of Corn Stalk Segments. Agriculture, 14 (2), 263. https://doi.org/10.3390/agriculture14020263

- Gonulol, E., Dalmis, I. S., Kayisoglu, B., Bayhan, Y., Kocabiyik, H. (2019). The evaluation of alternative stalk chopping methods in sunflower farming. Advances in Agriculture and Agricultural Sciences, 5 (1), 1–6. Available at: https://www.internationalscholarsjournals.com/articles/the-evaluation-of-alternative-stalk-chopping-methodsin-sunflower-farming.pdf

- Kaniovska, I. Yu., Stus, O. V. (2023). Matematychna statystyka. Obrobka doslidnykh danykh metodamy matematychnoi statystyky: rekomendatsii do vykonannia indyvidualnoho zavdannia. Kyiv: KPI im. Ihoria Sikorskoho, 128.

- Sholokhov, S. M., Samborskyi, I. I., Holovin, Yu. O. (2024). Teoretychni osnovy planuvannia eksperymentu ta obrobky eksperymentalnykh danykh. Kyiv: KPI im. Ihoria Sikorskoho, 159.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Viktor Sheichenko, Volodymyr Volskyi, Rostyslav Kotsiubanskyi, Vitalii Bonchyk, Vitaliy Shevchuk, Misha Shevchuk, Viacheslav Vovk, Oleksandr Shapoval

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.