Development of a simulation model of a WEB-oriented servo drive frequency control system based on “Digital Twins” technology

DOI:

https://doi.org/10.15587/2706-5448.2025.345825Keywords:

WEB control system, TIA Portal, Digital Twin, simulation model, PLC, frequency converter SinamicsAbstract

The object of this research is the information processes of interaction between virtual components of a WEB-oriented simulation model of a frequency control system for a synchronous servo drive. The research problem lies in the need for a comprehensive solution to the tasks of developing simulation models of control systems for technological objects based on advanced algorithms, procedures, and unified hardware and software tools.

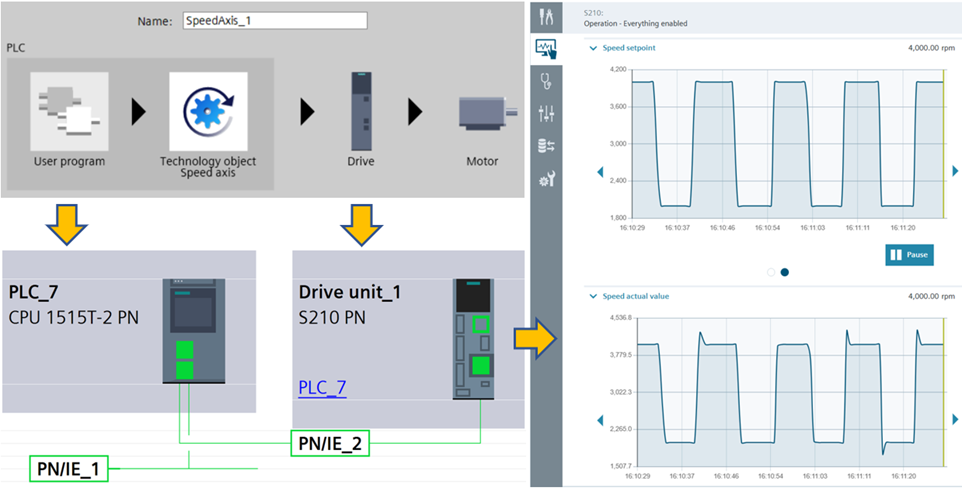

A project of a frequency control system for a SIMOTICS S-1FK2 synchronous servo drive was developed using a PLC S7-1500 and a FC SINAMICS S210 within the TIA Portal environment. Application software for the frequency control system was developed in FBD language with an integrated specialized technological object “SpeedAxis”.

During the development of the simulation model, a “Digital Twins” were generated for the frequency converter with an integrated synchronous servo drive. To ensure interaction between the virtual components of the simulation model, procedures for basic parameterization and loading of the TIA Portal project components into the “Digital Twins” were implemented.

Testing and investigation of the information exchange processes between the virtual components of the simulation model were carried out in “on-line” mode using the capabilities of the integrated WEB-server.

The tests were conducted at speeds of 2000 rpm and 4000 rpm, switched periodically every 12 sec. Parameters of the reference and actual speed, as well as the instantaneous voltage, current, torque, and output power of the virtual frequency converter, were measured and analyzed.

Based on the test results, the feasibility and correctness of the joint operation of the simulation model components in an isochronous real-time mode with a 1 ms synchronization cycle were confirmed, demonstrating the effectiveness of the approach based on “Digital Twins” technology.

References

- Luo, X., Liu, Q., Madathil, A. P., Xie, W. (2024). Predictive digital twin-driven dynamic error control for slow-tool-servo ultraprecision diamond turning. CIRP Annals, 73 (1), 377–380. https://doi.org/10.1016/j.cirp.2024.04.080

- Vered, Y., Elliott, S. J. (2023). The use of digital twins to remotely update feedback controllers for the motion control of nonlinear dynamic systems. Mechanical Systems and Signal Processing, 185, 109770. https://doi.org/10.1016/j.ymssp.2022.109770

- Wang, H., Yang, Z., Zhang, Q., Sun, Q., Lim, E. (2024). A Digital Twin Platform Integrating Process Parameter Simulation Solution for Intelligent Manufacturing. Electronics, 13 (4), 802. https://doi.org/10.3390/electronics13040802

- Ebadpour, M., Jamshidi, M. (Behdad), Talla, J., Hashemi-Dezaki, H., Peroutka, Z. (2023). Digital Twin Model of Electric Drives Empowered by EKF. Sensors, 23 (4), 2006. https://doi.org/10.3390/s23042006

- de Oliveira Hansen, J. P., da Silva, E. R., Bilberg, A., Bro, C. (2021). Design and development of Automation Equipment based on Digital Twins and Virtual Commissioning. Procedia CIRP, 104, 1167–1172. https://doi.org/10.1016/j.procir.2021.11.196

- Guerra-Zubiaga, D., Kuts, V., Mahmood, K., Bondar, A., Nasajpour-Esfahani, N., Otto, T. (2021). An approach to develop a digital twin for industry 4.0 systems: manufacturing automation case studies. International Journal of Computer Integrated Manufacturing, 34 (9), 933–949. https://doi.org/10.1080/0951192x.2021.1946857

- Balla, M., Haffner, O., Kučera, E., Cigánek, J. (2023). Educational Case Studies: Creating a Digital Twin of the Production Line in TIA Portal, Unity, and Game4Automation Framework. Sensors, 23 (10), 4977. https://doi.org/10.3390/s23104977

- Horvath, D., Klauco, M., Stremy, M. (2024). Virtual Commissioning with TIA Step7 and Simulink without S‐Functions. Journal of Engineering, 2024 (1). https://doi.org/10.1155/2024/2822711

- Uddin, M. M. (2021). Development of advanced process control for controlling a digital twin as a part of virtual commissioning. [Master’s thesis; University of Gävle]. Available at: https://www.diva-portal.org/smash/get/diva2:1599802/FULLTEXT01.pdf

- Catalog ST 70: Products for Totally Integrated Automation – SIMATIC (E86060-K4770-A101-C2-7600) (2025). Siemens. Available at: https://support.industry.siemens.com/cs/attachments/109744167/simatic-st70-complete-english-2025_1.pdf

- S7-1500 / S7-1500T Motion Control overview: Function Manual (Version 7.0, A5E03879256-AH) (2022). Siemens. Available at: https://support.industry.siemens.com/cs/attachments/109812056/s71500_s71500t_motion_control_overview_function_manual_en-US_en-US.pdf?utm_source

- Motion Control Drives D32: SINAMICS S210 servo drive system (Update 04/2025) (Catalog D32) (2025). Siemens. Available at: https://support.industry.siemens.com/cs/attachments/109754381/motion-control-drives-D32-complete-English-2025-01_Update-04-2025.pdf

- S210/S-1FK2/S-1FT2: Operating Instructions (A5E52380168B AF) (2025). Siemens. Available at: https://support.industry.siemens.com/cs/attachments/109982746/S210_S-1FK2_S-1FT2_op_instr_0525_en-US.pdf

- Totally Integrated Automation (TIA) documentation (2024). Siemens. Available at: https://docs.tia.siemens.cloud/

- TIA Openness – Automated Engineering: Application examples for production machine building (DI FA PMA APC) (2025). Siemens. Available at: https://support.industry.siemens.com/cs/document/109821826

- S7-PLCSIM Advanced: Function Manual (V7 Upd1) (A5E37039512-AJ) (2025). Siemens. Available at: https://support.industry.siemens.com/cs/attachments/109826194/s7-plcsim_advanced_function_manual_en-US.pdf

- DriveSim Engineer: Function Manual (A5E52754110B AD) (2024). Siemens. Available at: https://support.industry.siemens.com/cs/attachments/109986376/DriveSim_Engineer_fct_man_1224_en-US.pdf

- Nazarenko, I. V., Nikolaychuk, M. Ya., Ferenets, V. D., Sukhanov, D. Ye. (2014). Construction and modeling of unified control systems of actuating mechanisms for objects of gas-transport system. Eastern-European Journal of Enterprise Technologies, 1 (2 (67)), 41–48. https://doi.org/10.15587/1729-4061.2014.21204

- Zamikhovskіy, L., Levytskyi, I., Nykolaychuk, M. (2021). Designing a system that removes metallic inclusions from bulk raw materials on the belt conveyor. Eastern-European Journal of Enterprise Technologies, 3 (2 (111)), 79–87. https://doi.org/10.15587/1729-4061.2021.234235

- SIMATIC NET: Industrial Ethernet/PROFINET Industrial Ethernet (SYH_IE Net_76). Siemens Industry Online Support (2019). Siemens. Available at: https://support.industry.siemens.com/cs/attachments/27069465/SYH_IE Net_76.pdf

- Application Example. Configuring technology objects with the SIMATIC S7-1500 and SINAMICS S210 (New) in TIA Portal. SINAMICS S210. (2024). Siemens. Available at: https://support.industry.siemens.com/cs/document/109749795/configuring-technology-objects-with-simatic-s7-1500-and-sinamics-s210-in-tia-portal?dti=0&lc=en-MK

- Application example: Simulating HMI projects in connection with SIMATIC controllers and PLCSIM / PLCSIM Advanced (WinCC Unified V20, PLCSIM V20, PLCSIM Advanced V7) (2025). Siemens. Available at: https://support.industry.siemens.com/cs/attachments/109748099/109748099_Simulation_of_WinCC_Unified_and_Controllers_V2.pdf

- DriveSim Engineer (2024). Siemens. Available at: https://www.siemens.com/global/en/products/drives/digital-drivetrain/simulate/drivesim-engineer.html

- Application example: All about motion control with SIMATIC S7-1500 (Entry ID 109803969) (2025). Siemens. Available at: https://support.industry.siemens.com/cs/ww/en/view/109803969

- SINAMICS S – Drive optimization guide (2023). Siemens. Available at: https://support.industry.siemens.com/cs/document/60593549/sinamics-s-drive-optimization-guide?dti=0&lc=en-UA

- Zamikhovskyi, L., Nykolaychuk, M., Levytskyi, I. (2024). Organizing the automated system of dispatch control over pump units at water pumping stations. Eastern-European Journal of Enterprise Technologies, 5 (2 (131)), 61–75. https://doi.org/10.15587/1729-4061.2024.313531

- Zamikhovskyi, L., Zamikhovska, O., Ivanyuk, N., Mirzoieva, O., Nykolaychuk, M. (2025). Development of an anti-surge protection system for gas pumping units based on hardware and software vibration monitoring tools. Eastern-European Journal of Enterprise Technologies, 4 (2 (136)), 117–132. https://doi.org/10.15587/1729-4061.2025.337736

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Leonid Zamikhovskyі, Mykola Nykolaychuk, Ivan Levytskyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.