Determination of the efficiency of shot blasting of metal surfaces

DOI:

https://doi.org/10.15587/2706-5448.2025.348608Keywords:

energy balance, shot blasting, efficiency, ricochet velocityAbstract

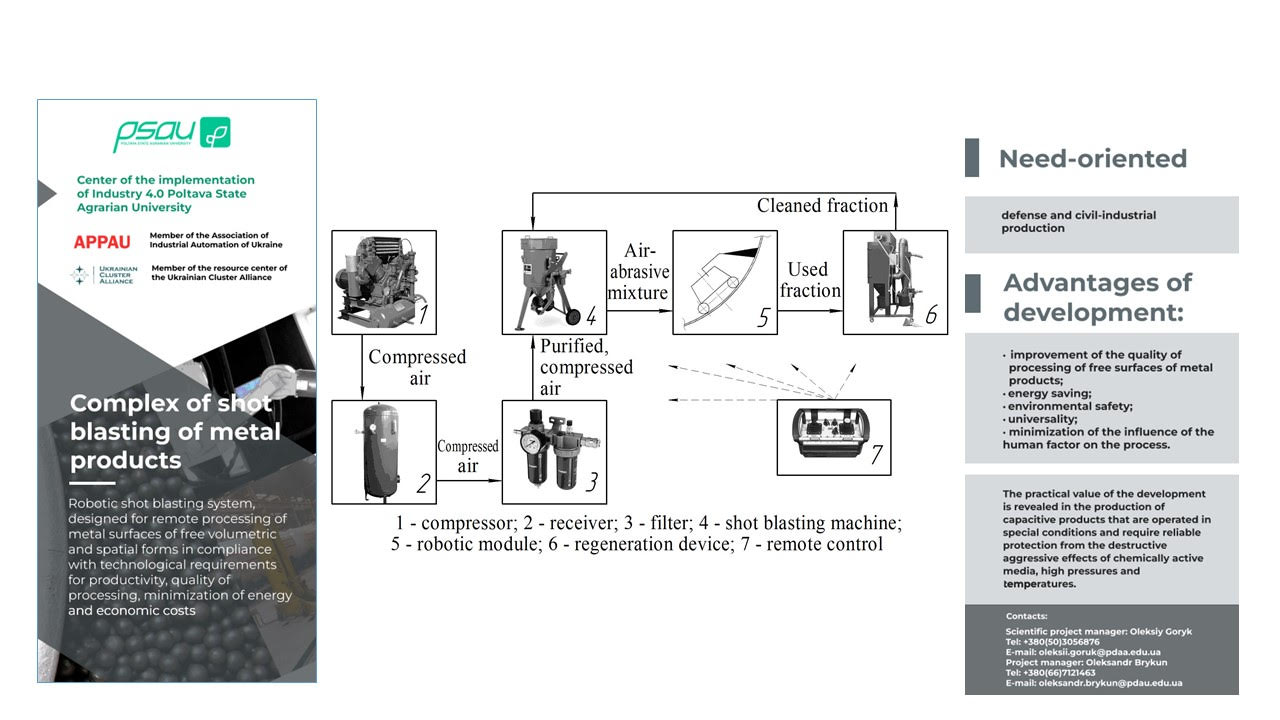

The object of this research is the process of transformation of kinetic energy of the attacking air-abrasive torch in the process of dynamic impact on metal surfaces of products during their shot blasting.

The importance of the research is due to the need to solve the problem of increasing the efficiency of the technological process of preparing metal surfaces of products by shot blasting for the subsequent application of protective, stable non-metallic coatings.

In the work, based on the energy balance of the “shot-obstacle” system, a method for determining the efficiency coefficient of the shot blasting surface preparation process was developed, which was associated with the torch energy recovery coefficient. The relationship of the coefficients with the potential energy of the surface layer accumulated in the process of elastic deformation was established. The depth of the hole formed by the shot on the surface of the attacked body was taken as a measure of this energy. When determining the depth of the hole, the deformation of an elementary cylindrical element clamped in the surface layer of the attacked body was considered, the dimensions of which are compatible with the dimensions of the elastic deformation hole.

The classical recovery coefficient is not a characteristic criterion for revealing the physical aspects of the complex multifactorial shot blasting process. The ease of application in practical calculations, especially when establishing the productivity of the process, prompts the search for improving the methods of its determination, since the existing models of an ideal impact in this case are not capable. This coefficient at average attack speeds of 100–120 m/s and angles of 40° < a < 70° turned out to be 15–20% less than the classical one.

The obtained research results can be used to increase the productivity of the shot blasting process of products of the defense, agricultural, machine-building, chemical, aviation and other industries.

References

- Boettcher, R., Kunik, M., Eichmann, S., Russell, A., Mueller, P. (2017). Revisiting energy dissipation due to elastic waves at impact of spheres on large thick plates. International Journal of Impact Engineering, 104, 45–54. https://doi.org/10.1016/j.ijimpeng.2017.02.012

- Goryk, O., Koval’chuk, S., Brykun, O., Aksonov, S. (2022). Assessment of Quality Criteria of Shot Blasting Cleaning of the Inner Surfaces of Chemically Resistant Containers. Advances in Mechanical and Power Engineering, 98–107. https://doi.org/10.1007/978-3-031-18487-1_10

- Basdeki, M., Apostolopoulos, C. (2022). The Effect of the Shot Blasting Process on the Dynamic Response of Steel Reinforcement. Metals, 12 (6), 1048. https://doi.org/10.3390/met12061048

- Lai, J., Shen, X., Yuan, X., Li, D., Gong, X., Zhao, F. et al. (2024). The Effect of Shot Blasting Abrasive Particles on the Microstructure of Thermal Barrier Coatings Containing Ni-Based Superalloy. Coatings, 14 (10), 1312. https://doi.org/10.3390/coatings14101312

- Melentiev, R. (2023). Physical theories of solid particle erosion and abrasive jet wear. Journal of Manufacturing Processes, 106, 422–452. https://doi.org/10.1016/j.jmapro.2023.10.014

- Yang, J., Qu, K., Yang, J. (2021). Fatigue performance of Q355B steel substrate treated by grit blasting with and without subsequent cold spraying with Al and Cu. Surface and Coatings Technology, 405, 126662. https://doi.org/10.1016/j.surfcoat.2020.126662

- Tawade, P., Shembale, S., Hussain, S., Sabiruddin, K. (2023). Effects of Different Grit Blasting Environments on the Prepared Steel Surface. Journal of Thermal Spray Technology, 32 (5), 1535–1553. https://doi.org/10.1007/s11666-023-01585-3

- Melo, K. R. B., de Pádua, T. F., Lopes, G. C. (2021). A coefficient of restitution model for particle–surface collision of particles with a wide range of mechanical characteristics. Advanced Powder Technology, 32 (12), 4723–4733. https://doi.org/10.1016/j.apt.2021.10.023

- Liu, X., Chen, W., Shi, H. (2022). Improvement of Contact Force Calculation Model Considering Influence of Yield Strength on Coefficient of Restitution. Energies, 15 (3), 1041. https://doi.org/10.3390/en15031041

- Li, T., Li, R., Chi, Z., Zhang, Y., Yang, H. (2024). Experimental Study on Coefficient of Restitution of Small-Sized Spherical Particles during Low-Speed Impact. Condensed Matter, 9 (1), 18. https://doi.org/10.3390/condmat9010018

- Chen, X., Wang, L.-W., Yu, Q., Zhang, F., Mo, K., Ming, S.-L. et al. (2022). Experimental and Numerical Analysis on the Impact Wear Behavior of TP316H Steel. Materials, 15 (8), 2881. https://doi.org/10.3390/ma15082881

- Meyer, N., Wagemann, E. L., Jackstadt, A., Seifried, R. (2022). Material and particle size sensitivity analysis on coefficient of restitution in low-velocity normal impacts. Computational Particle Mechanics, 9 (6), 1293–1308. https://doi.org/10.1007/s40571-022-00471-z

- Tarodiya, R., Levy, A. (2024). Numerical investigation of collision characteristics of non-spherical particles on ductile surfaces under normal impact. Computational Particle Mechanics, 11 (6), 2693–2699. https://doi.org/10.1007/s40571-024-00746-7

- Green, I. (2022). The prediction of the coefficient of restitution between impacting spheres and finite thickness plates undergoing elastoplastic deformations and wave propagation. Nonlinear Dynamics, 109 (4), 2443–2458. https://doi.org/10.1007/s11071-022-07522-3

- Gorik, A. V., Zinkovskii, A. P., Chernyak, R. E., Brikun, A. N. (2016). Elastoplastic Deformation of the Surface Layer of Machinery Constructions on Shot Blasting. Strength of Materials, 48 (5), 650–657. https://doi.org/10.1007/s11223-016-9808-6

- Goryk, O., Koval’chuk, S., Brykun, O., Lapenko, T. (2023). The stability period of attacking shots in the process of shot blasting of metal surfaces. IX international conference on actual problems of engineering mechanics (APEM2022), 2840, 030002. https://doi.org/10.1063/5.0167634

- Goryk, O., Koval’chuk, S., Brykun, O., Chernyak, R. (2020). Viscoelastic Resistance of the Surface Layer of Steel Products to Shock Attack of a Spherical Pellet. Key Engineering Materials, 864, 217–227. https://doi.org/10.4028/www.scientific.net/kem.864.217

- Fan, Y., Wang, H., Zhou, T., Zou, L., Jiang, Z., Hu, M. (2024). Prediction of Coefficient of Restitution for Impact Elastoplastic Spheres Considering Finite Plate Thickness. Chinese Journal of Mechanical Engineering, 37 (1). https://doi.org/10.1186/s10033-024-01066-w

- Ji, Z.-M., Chen, Z.-J., Niu, Q.-H., Wang, T.-H., Wang, T.-J. et al. (2020). A calculation model of the normal coefficient of restitution based on multi-factor interaction experiments. Landslides, 18 (4), 1531–1553. https://doi.org/10.1007/s10346-020-01556-7

- Xie, X., Zhang, L., Zhu, L., Li, Y., Hong, T., Yang, W. et al. (2023). State of the Art and Perspectives on Surface-Strengthening Process and Associated Mechanisms by Shot Peening. Coatings, 13 (5), 859. https://doi.org/10.3390/coatings13050859

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Оleksii Goryk, Oleksandr Brykun, Oleg Kalashnykov, Andrii Buchynskyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.