Analysis of the operation of marine diesel engines when using engine oils with different structural characteristics

DOI:

https://doi.org/10.15587/2706-5448.2022.265868Keywords:

marine trunk diesel engines, lubrication of marine diesel engines, engine oil, lubricating layer thickness, wetting contact angleAbstract

The object of research is the process of lubrication of marine trunk diesel engines. The subject of research is marine diesel engine oils, which provide lubrication, cooling and separation of friction surfaces.

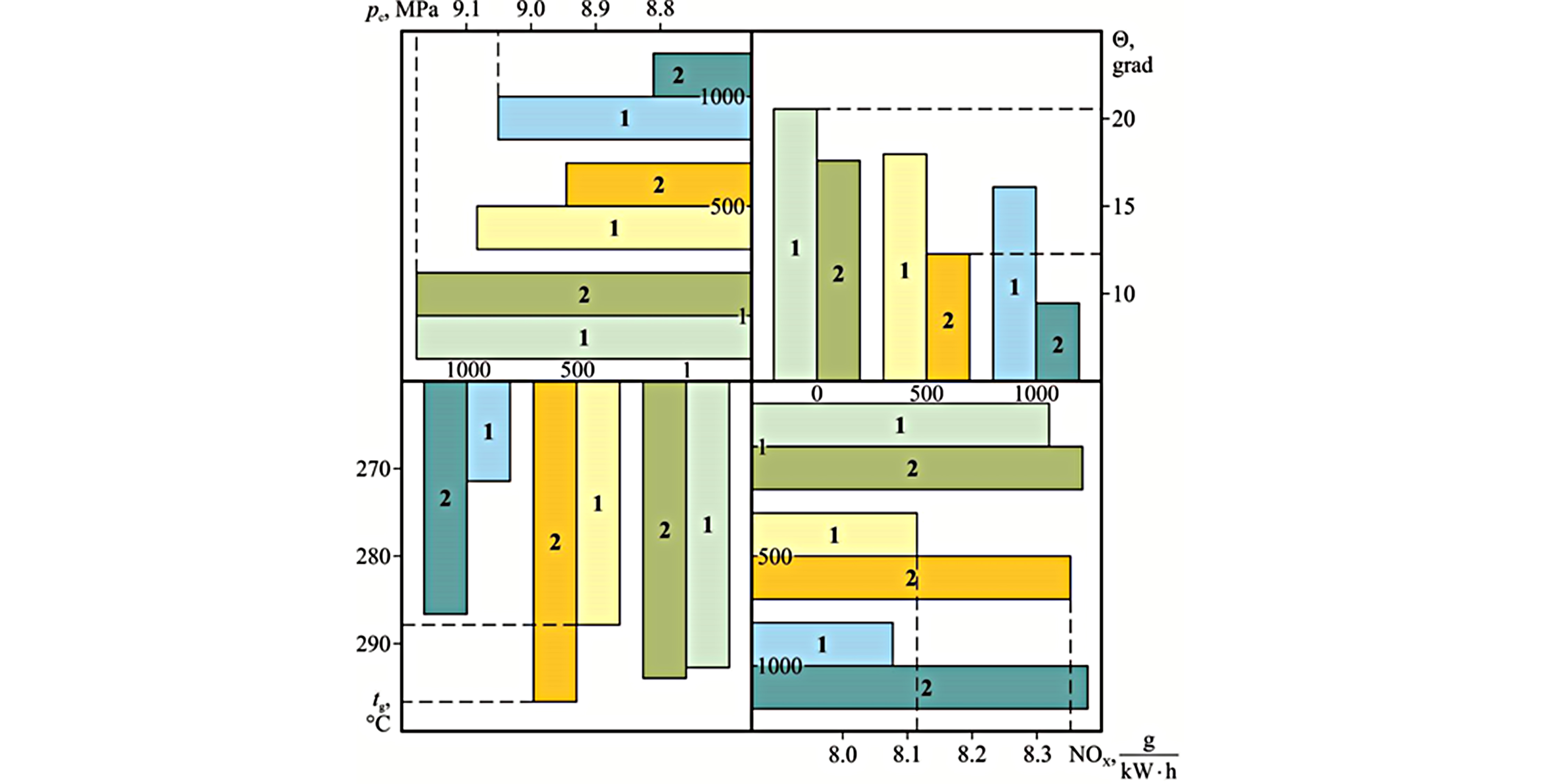

The analysis of the operation of marine diesel engines using motor oils with different structural characteristics is carried out. The studies are carried out on Yanmar 6EY18AL diesel engines of a Multipurpose Vessel class ship with deadweight of 27540 tons. The objective of research is to determine the effect of the structural characteristics of the oil layer (contact angle and thickness) on the performance parameters of a marine diesel engine and the performance characteristics of the oil used in its circulating lubrication system. At the same time, the compression pressure, the concentration of nitrogen oxides in the exhaust gases, and the temperature of the exhaust gases after the cylinder are considered as the operating parameters of the diesel engine; as performance characteristics of the oil – its Base Number, as well as its Wear and Contaminant Elements. The studies are carried out on two diesel engines of the same type, in the circulating lubrication system of which oils with different structural characteristics were used. Structural characteristics of the oil layer were determined by ellipsometry. The operational characteristics of the diesel engine – using the Doctor diagnostic system. Oil performance – by spectrographic analysis. It has been established that an increase in the contact angles of wetting and the thickness of the oil layer improves the heat and power and environmental performance of a diesel engine. At the same time (for the period of operation of diesel engines 500–1000 hours), the decrease in compression pressure in the cylinder slows down, the temperature of gases after the cylinder decreases, and the emission of nitrogen oxides with exhaust gases decreases. In addition, the wear of diesel parts and oil oxidation are reduced.

The information obtained in the course of the study on the structural characteristics of motor oils will provide the possibility of their selection and further use of those that will contribute to a better maintenance of the operational performance of marine diesel engines.

References

- Sagin, S., Madey, V., Stoliaryk, T. (2021). Analysis of mechanical energy losses in marine diesels. Technology Audit and Production Reserves, 5 (2 (61)), 26–32. doi: https://doi.org/10.15587/2706-5448.2021.239698

- Fomin, O., Lovska, A., Kučera, P., Píštěk, V. (2021). Substantiation of Improvements for the Bearing Structure of an Open Car to Provide a Higher Security during Rail/Sea Transportation. Journal of Marine Science and Engineering, 9 (8), 873. doi: https://doi.org/10.3390/jmse9080873

- Sagin, S. V., Solodovnikov, V. G. (2015). Cavitation treatment of high-viscosity marine fuels for medium-speed diesel engines. Modern Applied Science, 9 (5), 269–278. doi: https://doi.org/10.5539/mas.v9n5p269

- Maryanov, D. (2021). Development of a method for maintaining the performance of drilling fluids during transportation by Platform Supply Vessel. Technology Audit and Production Reserves, 5 (2 (61)), 15–20. doi: https://doi.org/10.15587/2706-5448.2021.239437

- Maryanov, D. (2022). Control and regulation of the density of technical fluids during their transportation by sea specialized vessels. Technology Audit and Production Reserves, 1 (2 (63)), 19–25. doi: https://doi.org/10.15587/2706-5448.2022.252336

- Sagin, S. V., Semenov, O. V. (2016). Marine Slow-Speed Diesel Engine Diagnosis with View to Cylinder Oil Specification. American Journal of Applied Sciences, 13 (5), 618–627. doi: https://doi.org/10.3844/ajassp.2016.618.627

- Popovskii, Yu. M., Sagin, S. V., Khanmamedov, S. A., Grebenyuk, M. N., Teregerya, V. V. (1996). Designing, calculation, testing and reliability of machines: influence of anisotropic fluids on the operation of frictional components. Russian Engineering Research, 16 (9), 1–7.

- Nahim, H. M., Younes, R., Nohra, C., Ouladsine, M. (2015). Complete modeling for systems of a marine diesel engine. Journal of Marine Science and Application, 14 (1), 93–104. doi: https://doi.org/10.1007/s11804-015-1285-y

- Sagin, S. V., Semenov, O. V. (2016). Motor Oil Viscosity Stratification in Friction Units of Marine Diesel Motors. American Journal of Applied Sciences, 13 (2), 200–208. doi: https://doi.org/10.3844/ajassp.2016.200.208

- Zablotsky, Y. V., Sagin, S. V. (2016). Enhancing Fuel Efficiency and Environmental Specifications of a Marine Diesel When using Fuel Additives. Indian Journal of Science and Technology, 9 (46), 353–362. doi: https://doi.org/10.17485/ijst/2016/v9i46/107516

- Zablotsky, Y. V., Sagin, S. V. (2016). Maintaining Boundary and Hydrodynamic Lubrication Modes in Operating High-pressure Fuel Injection Pumps of Marine Diesel Engines. Indian Journal of Science and Technology, 9 (20), 208–216. doi: https://doi.org/10.17485/ijst/2016/v9i20/94490

- Zhou, Y., Li, W., Stump, B., Connatser, R., Lazarevic, S., Qu, J. (2018). Impact of Fuel Contents on Tribological Performance of PAO Base Oil and ZDDP. Lubricants, 6 (3), 79. doi: https://doi.org/10.3390/lubricants6030079

- Guo, Z.-W., Yuan, C.-Q., Bai, X.-Q., Yan, X.-P. (2018). Experimental Study on Wear Performance and Oil Film Characteristics of Surface Textured Cylinder Liner in Marine Diesel Engine. Chinese Journal of Mechanical Engineering, 31 (1). doi: https://doi.org/10.1186/s10033-018-0252-3

- Lijesh, K. P., Khonsari, M. M. (2018). On the Degradation of Tribo-components in Boundary and Mixed Lubrication Regimes. Tribology Letters, 67 (1). doi: https://doi.org/10.1007/s11249-018-1125-8

- Chong, W. W. F., Hamdan, S. H., Wong, K. J., Yusup, S. (2019). Modelling Transitions in Regimes of Lubrication for Rough Surface Contact. Lubricants, 7 (9), 77. doi: https://doi.org/10.3390/lubricants7090077

- Zavos, A. (2021). Effect of Coating and Low Viscosity Oils on Piston Ring Friction under Mixed Regime of Lubrication through Analytical Modelling. Lubricants, 9 (12), 124. doi: https://doi.org/10.3390/lubricants9120124

- Delprete, C., Razavykia, A. (2017). Piston ring–liner lubrication and tribological performance evaluation: A review. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 232 (2), 193–209. doi: https://doi.org/10.1177/1350650117706269

- Fomin, O., Lovska, A., Skok, P., Rogovskii, I. (2021). Determination of the dynamic load of the carrying structure of the hopper wagon with the actual dimensions of structural elements. Technology Audit and Production Reserves, 1 (1 (57)), 6–11. doi: https://doi.org/10.15587/2706-5448.2021.225458

- Cherniak, L., Varshavets, P., Dorogan, N. (2017). Development of a mineral binding material with elevated content of red mud. Technology Audit and Production Reserves, 3 (3 (35)), 22–28. doi: https://doi.org/10.15587/2312-8372.2017.105609

- Dzyura, V., Maruschak, P., Prentkovskis, O. (2021). Determining Optimal Parameters of Regular Microrelief Formed on the End Surfaces of Rotary Bodies. Algorithms, 14 (2), 46. doi: https://doi.org/10.3390/a14020046

- Sumardiyanto, D., Susilowati, S. (2021) Analysis the Occurrence of Wear on Crank Pin Bearing in Diesel Engine. Journal of Mechanical Engineering and Automation, 10 (1), 19–23.

- Salaheldin, A., Xiqun, L., Zheng, Q. (2014). Effect of cylinder liner oil grooves shape on two-stroke marine diesel engine’s piston ring friction force. Advances in Mechanical Engineering, 7 (2), 837960. doi: https://doi.org/10.1155/2014/837960

- Abril, S. O., Del Socorro Fonseca-Vigoya, M., Pabón-León, J. (2022). CFD Analysis of the Effect of Dimples and Cylinder Liner Honing Groove on the Tribological Characteristics of a Low Displacement Engine. Lubricants, 10 (4), 61. doi: https://doi.org/10.3390/lubricants10040061

- Rahmani, R., Rahnejat, H., Fitzsimons, B., Dowson, D. (2017). The effect of cylinder liner operating temperature on frictional loss and engine emissions in piston ring conjunction. Applied Energy, 191 (1), 568–581. doi: https://doi.org/10.1016/j.apenergy.2017.01.098

- Senatore, A., Risitano, G., Scappaticci, L., D’Andrea, D. (2021). Investigation of the Tribological Properties of Different Textured Lead Bronze Coatings under Severe Load Conditions. Lubricants, 9 (4), 34. doi: https://doi.org/10.3390/lubricants9040034

- Hu, Y., Meng, X., Xie, Y. (2018). A new efficient flow continuity lubrication model for the piston ring-pack with consideration of oil storage of the cross-hatched texture. Tribology International, 119, 443–463. doi: https://doi.org/10.1016/j.triboint.2017.11.027

- Yu, A., Niu, W., Hong, X., He, Y., Wu, M., Chen, Q., Ding, M. (2018). Influence of tribo-magnetization on wear debris trapping processes of textured dimples. Tribology International, 121, 84–93. doi: https://doi.org/10.1016/j.triboint.2018.01.046

- Mohamad, S. A., Kamel, M. A. (2020). Optimization of cylinder liner macro-scale surface texturing in marine diesel engines based on teaching–learning-based optimization algorithm. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 235 (2), 329–342. doi: https://doi.org/10.1177/1350650120911563

- Sagin, S. V. (2019). Decrease in mechanical losses in high-pressure fuel equipment of marine diesel engines. Scientific research of the SCO countries: synergy and integration. Part 1. Beijing: PRC, 139–145. doi: https://doi.org/10.34660/INF.2019.15.36258

- Peng, C. (2021). Wear Test of Cylinder Liner and Piston Ring of Marine Diesel Engine Based on Computer Simulation Technology. Journal of Physics: Conference Series, 2074 (1), 012033. doi: https://doi.org/10.1088/1742-6596/2074/1/012033

- Nouri, J., Vasilakos, I., Yan, Y., Reyes-Aldasoro, C.-C. (2019). Effect of Viscosity and Speed on Oil Cavitation Development in a Single Piston-Ring Lubricant Assembly. Lubricants, 7 (10), 88. doi: https://doi.org/10.3390/lubricants7100088

- Vadivel, A., Periyasamy, S. (2020). Experimental Investigation of Thermal Barrier (8YSZ-MGO-TIO2) Coated Piston used in Diesel Engine. Journal of Applied Fluid Mechanics, 13 (4), 1157–1165. doi: https://doi.org/10.36884/jafm.13.04.30825

- Vural, E. (2020). The Study of Microstructure and Mechanical Properties of Diesel Engine Piston Coated with Carbide Composites by Using HVOF Method. Transactions of the Indian Institute of Metals, 73 (10), 2613–2622. doi: https://doi.org/10.1007/s12666-020-02055-y

- Sagin, S. V., Solodovnikov, V. G. (2017). Estimation of Operational Properties of Lubricant Coolant Liquids by Optical Methods. International Journal of Applied Engineering Research, 12 (19), 8380–8391.

- Sagin, S. V. (2018) Improving the performance parameters of systems fluids. Austrian Journal of Technical and Natural Sciences, 7-8, 55–59.

- Zavos, A., Nikolakopoulos, P. G. (2021). Investigation of the top compression ring power loss and energy consumption for different engine conditions. Tribology – Materials, Surfaces & Interfaces, 16 (2), 130–142. doi: https://doi.org/10.1080/17515831.2021.1907682

- Sagin, S. V., Kuropyatnyk, O. A., Zablotskyi, Y. V., Gaichenia, O. V. (2022). Supplying of Marine Diesel Engine Ecological Parameters. Naše More, 69 (1), 53–61. doi: https://doi.org/10.17818/nm/2022/1.7

- Kuropyatnyk, O. A., Sagin, S. V. (2019). Exhaust Gas Recirculation as a Major Technique Designed to Reduce NOх Emissions from Marine Diesel Engines. Naše More, 66 (1), 1–9. doi: https://doi.org/10.17818/nm/2019/1.1

- Fernández-Feal, M., Fernández-Feal, M., Sánchez-Fernández, L., Pérez-Prado, J. (2018). Study of Metal Concentration in Lubricating Oil with Predictive Purposes. Current Journal of Applied Science and Technology, 27 (6), 1–12. doi: https://doi.org/10.9734/cjast/2018/41472

- Sagin, S. V., Kuropyatnik, A. A. (2017) Application of the system of recirculation of exhaust gases for the reduction of the concentration of nitric oxides in the exhaust gases of the ship diesels. American Scientific Journal, 15 (2), 67–71.

- Sagin, S. V., Kuropyatnyk, O. A. (2021). Using exhaust gas bypass for achieving the environmental performance of marine diesel engines. The Austrian Journal of Technical and Natural Sciences, 7-8, 36–43. doi: https://doi.org/10.29013/ajt-21-7.8-36-43

- Sagin, S. V., Stoliaryk, T. O. (2021). Comparative assessment of marine diesel engine oils. The Austrian Journal of Technical and Natural Sciences, 7-8, 29–35. doi: https://doi.org/10.29013/ajt-21-7.8-29-35

- Dvořáková, Ľ., Kruml, S., Ryzák, D. (2021). Antipalindromic numbers. Acta Polytechnica, 61 (3), 428–434. doi: https://doi.org/10.14311/ap.2021.61.0428

- Madey, V. V. (2021). Usage of biodiesel in marine diesel engines. The Austrian Journal of Technical and Natural Sciences, 7-8, 18–21. doi: https://doi.org/10.29013/ajt-21-7.8-18-21

- Sagin, S. V., Kuropyatnyk, O. A. (2018). The Use of Exhaust Gas Recirculation for Ensuring the Environmental Performance of Marine Diesel Engines. Naše More, 65 (2), 78–86. doi: https://doi.org/10.17818/nm/2018/2.3

- Chu Van, T., Ramirez, J., Rainey, T., Ristovski, Z., Brown, R. J. (2019). Global impacts of recent IMO regulations on marine fuel oil refining processes and ship emissions. Transportation Research Part D: Transport and Environment, 70, 123–134. doi: https://doi.org/10.1016/j.trd.2019.04.001

- Popovskii, A. Yu., Altoiz, B. A., Butenko, V. F. (2019). Structural Properties and Model Rheological Parameters of an ELC Layer of Hexadecane. Journal of Engineering Physics and Thermophysics, 92 (3), 703–709. doi: https://doi.org/10.1007/s10891-019-01980-0

- Lovska, A., Fomin, O., Píštěk, V., Kučera, P. (2020). Dynamic Load Modelling within Combined Transport Trains during Transportation on a Railway Ferry. Applied Sciences, 10 (16), 5710. doi: https://doi.org/10.3390/app10165710

- Lopatin, O. P. (2020). Study of the influence of the degree of exhaust gas recirculation on the working process of a diesel. Journal of Physics: Conference Series, 1515 (4), 042021. doi: https://doi.org/10.1088/1742-6596/1515/4/042021

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Tymur Stoliaryk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.