Increase of cracking resistance of ceramic masses of low-plastic clay

DOI:

https://doi.org/10.15587/2706-5448.2023.274629Keywords:

ceramic materials, clay raw materials, zeolite, drying, mechanical strength, siliceous materials, building ceramicsAbstract

The object of research is the physical and chemical processes of forming the structure and properties of ceramic masses based on local low-melting clay raw materials of the Kyiv region of Ukraine by adjusting the chemical and mineralogical composition and technological regimes.

Building ceramic materials are durable, ecological and natural. They provide increased comfort of buildings due to the creation of a favorable temperature and humidity climate of the premises. When using low-melting raw materials in production, there is a need to develop ways and methods to improve the quality of building ceramics. The efficiency of the manufacture of ceramic products largely depends on the processes that occur during drying. This is of crucial importance and affects the quality of finished products and accounts for 10–12 % of the total cost of finished products.

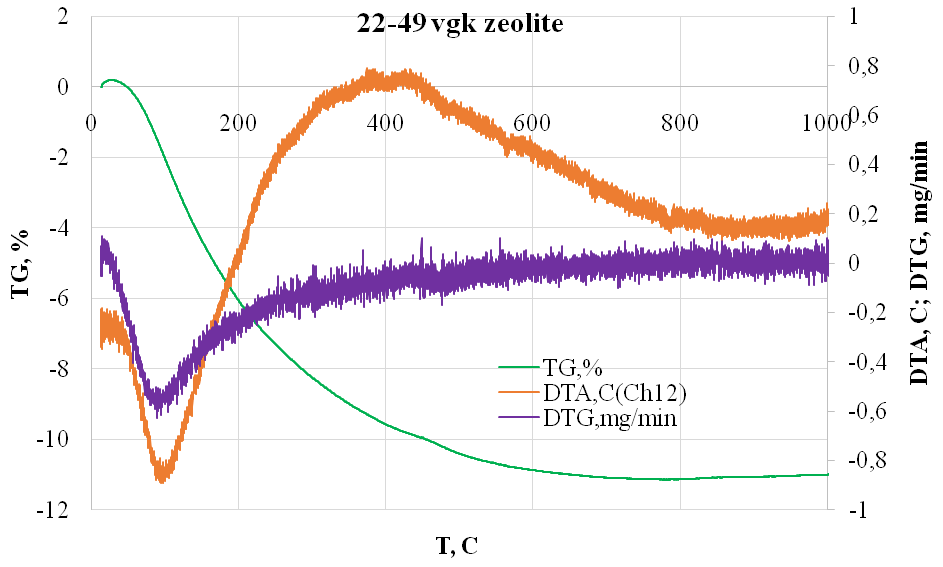

Polymineral clay compositions with the addition of natural mineral raw materials are mainly used for the production of construction materials. For effective use of these materials, it is necessary to study their technological properties. Therefore, the question of researching masses based on low-melting clays with high sensitivity to drying, and the use of zeolite-containing mineral rock as an admixture is relevant. This will allow expanding the nomenclature of building ceramics products. Modern physico-chemical and physico-technological methods of research of raw materials and masses based on them during drying were used to solve the task of obtaining ceramic material from local raw materials with the use of a non-deficient natural additive of zeolite-containing rock as an admixture. The conducted studies indicate that the addition of zeolite-containing rock can be used to improve the drying properties of ceramic masses based on low-melting clays. Adding admixture of zeolite-containing rock also increased the compressive strength of finished products, which ensures defect-free transportation of products to other technological operations.

References

- Dole, M. (2021). Ceramic Technology Diploma&Engineering MCQ. Objective question answers. India, 107.

- Shestakov, V. L. (2002). Tekhnolohiia keramichnykh stinovykh i lytsiuvalnykh materialiv. Rivne: UDUVHiP, 243.

- Zaccaron, A., de Souza Nandi, V., Dal Bó, M., Arcaro, S., Bernardin, A. M. (2022). The behavior of different clays subjected to a fast-drying cycle for traditional ceramic manufacturing. Journal of King Saud University – Engineering Sciences. doi: https://doi.org/10.1016/j.jksues.2022.05.003

- Gömze, L. A., Gömze, L. N., Kurovics, E., Benedek, G. (2019). Conventional Brick Clays as a Challenge of Materials Science – New Explanation of Drying Sensitivities. IOP Conference Series: Materials Science and Engineering, 613, 012005. doi: https://doi.org/10.1088/1757-899x/613/1/012005

- Mançuhan, E. (2009). Analysis and Optimization of Drying of Green Bricks in a Tunnel Dryer. Drying Technology, 27 (5), 707–713. doi: https://doi.org/10.1080/07373930902827692

- Terzić, A., Pezo, L., Mitić, V. V. (2016). Optimization of drying through analytical modeling: clays as bonding agents in refractory materials. Ceramics International, 42 (5), 6301–6311. doi: https://doi.org/10.1016/j.ceramint.2016.01.018

- Aungatichart, P., Wada, S. (2009). Correlation between Bigot and Ratzenberger drying sensitivity indices of red clay from Ratchaburi province (Thailand). Applied Clay Science, 43 (2), 182–185. doi: https://doi.org/10.1016/j.clay.2008.08.001

- Moritz, T., Werner, G., Tomandl, G. (1999). Drying of Ceramic Layers with a Graded Pore Structure. Journal of Porous Materials, 6 (2), 111–117. doi: https://doi.org/10.1023/a:1009675204731

- Vakalova, T. V., Revva, I. B. (2020). Use of zeolite rocks for ceramic bricks based on brick clays and clay loams with high drying sensitivity. Construction and Building Materials, 255, 119324. doi: https://doi.org/10.1016/j.conbuildmat.2020.119324

- Ibrahim, J. E. F. M., Tihtih, M., Gömze, L. A. (2021). Environmentally-friendly ceramic bricks made from zeolite-poor rock and sawdust. Construction and Building Materials, 297, 123715. doi: https://doi.org/10.1016/j.conbuildmat.2021.123715

- Paleichuk, V. S., Krupa, V. A., Tkach, V. V. (2000). Specifics of drying of building ceramics made using lubricant-coolant waste. Glass and Ceramics, 57 (3-4), 98–100. doi: https://doi.org/10.1007/bf02681518

- Vakalova, T. V., Revva, I. B. (2022). Highly porous building ceramics based on «clay-ash microspheres» and «zeolite-ash microspheres» mixtures. Construction and Building Materials, 317, 125922. doi: https://doi.org/10.1016/j.conbuildmat.2021.125922

- Wojdyr, M. (2010). Fityk: a general-purpose peak fitting program. Journal of Applied Crystallography, 43 (5), 1126–1128. doi: https://doi.org/10.1107/s0021889810030499

- Spasonova, L., Subbota, І., Sholom, А. (2021). Devising technology for utilizing water treatment waste to produce ceramic building materials. Eastern-European Journal of Enterprise Technologies, 1 (10 (109)), 14–22. doi: https://doi.org/10.15587/1729-4061.2021.225256

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Іrіna Subota, Larysa Spasonova, Аnastasia Sholom

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.