Use of consumer polymer С-РET containers in food production technologies

DOI:

https://doi.org/10.15587/2706-5448.2023.275074Keywords:

polymer packaging, C-PET packaging, heat resistance of polymer films, clogging strength, heat treatment modesAbstract

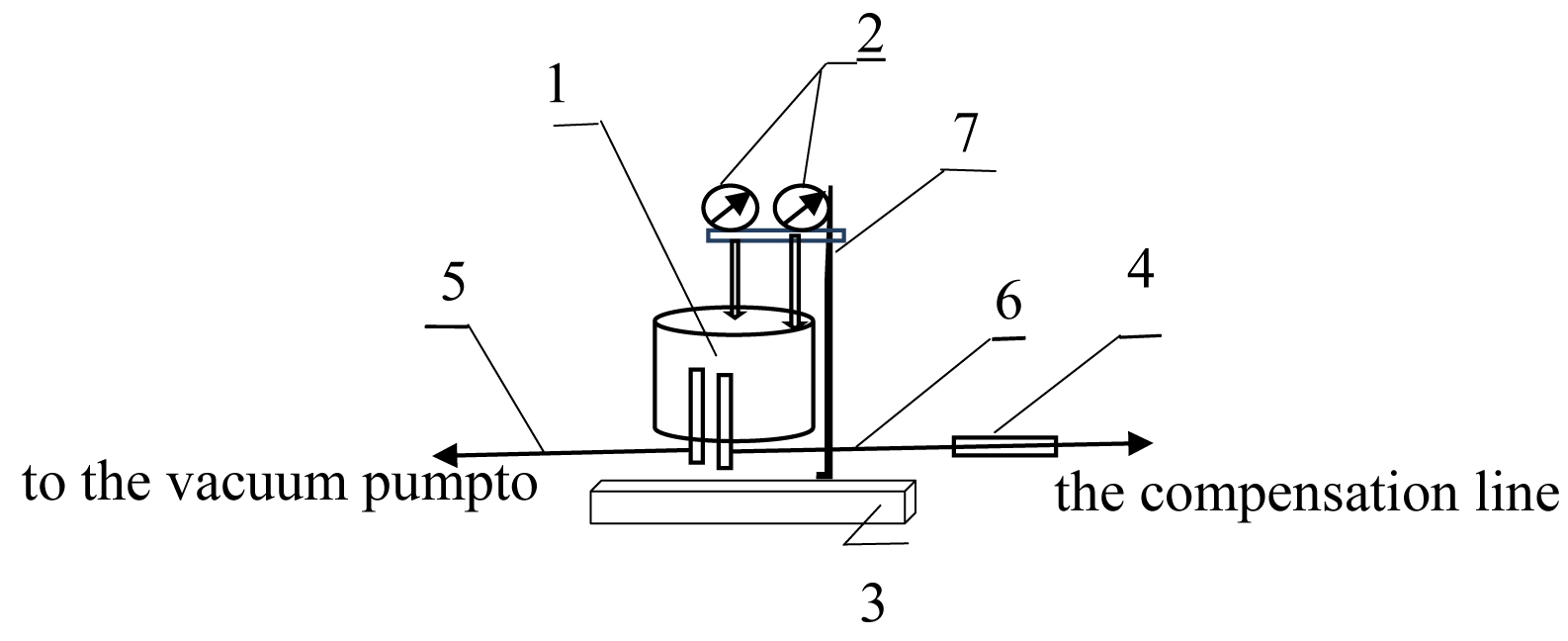

Different types of consumer containers are used for food packaging: glass, metal, polymer. Polymer containers are in the greatest demand among consumers, due to such advantages as cheapness, small weight, unlimited range of products and volume, pleasant, bright appearance. In the food industry, hard, semi-hard, soft and other consumer polymer containers are used. To use such packaging in technology with high-temperature heat treatment of food products, it must have a heat-resistant barrier layer. Therefore, the object of research is a polymer combined C-PET container, which consists of a semi-rigid container-tray and a heat-resistant multi-layer polymer soft film for its closure. C-PET packaging is made of barrier polymer materials that ensure its mechanical resistance to high temperatures. Therefore, such containers can withstand high-temperature processing and guarantee the tightness of the package and the microbiological stability of the product during storage. Each polymer material has its own specific indicators of heat resistance. The work solves the problem of using the latest polymeric C-PET containers for long-term storage food products, investigates the conditions for preserving the tightness of the containers during heat treatment, which are ensured by the clogging strength parameter. Different types of polymer films for sealing C-PET packaging with the product are also investigated and their mechanical characteristics are compared. In the course of the study, a standard membrane-compensation method was used to measure the clogging strength or depressurization pressure of the package. The essence of the obtained results: the parameters of the use of different types of polymer films of different types were experimentally determined, on the basis of which the type of film was chosen, which ensures the clogging strength of C-PET containers. The results are explained by the fact that the depressurization pressure value obtained will allow to develop scientifically based thermal modes of sterilization and pasteurization for food products in C-PET containers. This will make it possible in practice for enterprises to apply the same regimes and produce high-quality, biologically stable, safe food products with a long shelf life.

Supporting Agency

- Presentation of research in the form of publication through financial support in the form of a grant from SUES (Support to Ukrainian Editorial Staff).

References

- Verkhivker, Y., Myroshnichenko, E. (2021). Modern types of polymer containers for canned food. Tovaroznavchiy Visnik, 1 (14), 6–17. doi: https://doi.org/10.36910/6775-2310-5283-2021-14-1

- Pishchevaia upakovka: vidy, tekhnologii proizvodstva i tendentcii razvitiia otrasli. Available at: https://www.kp.ru/guide/pishchevaja-upakovka.html Last accessed: 15.01.2023

- Nisticò, R. (2020). Polyethylene terephthalate (PET) in the packaging industry. Polymer Testing, 90, 106707. doi: https://doi.org/10.1016/j.polymertesting.2020.106707

- Auras, R. A., Singh, S. P., Singh, J. J. (2005). Evaluation of oriented poly(lactide) polymers vs. existing PET and oriented PS for fresh food service containers. Packaging Technology and Science, 18 (4), 207–216. doi: https://doi.org/10.1002/pts.692

- Butylki iz barernogo PET: tekhnologii i rynok (2020). Available at: http://newchemistry.ru/letter.php?n_id=1617

- Poliformaldegidy (2023). Material Wizard. Available at: https://materialwizard.com.ua/poliformaldegidy/

- Termoplastichnye poliefiry, polietilentereftalat (PET). Plastik technologies. Available at: https://ptl.by/index.pl?act=PRODUCT&id=44

- Benyathiar, P., Kumar, P., Carpenter, G., Brace, J., Mishra, D. K. (2022). Polyethylene Terephthalate (PET) Bottle-to-Bottle Recycling for the Beverage Industry: A Review. Polymers, 14 (12), 2366. doi: https://doi.org/10.3390/polym14122366

- Innovatcionnaia upakovka. Available at: https://mega-tray.ru/pack/sealable-trays/cpet

- RR i RR/RE. Pentaplast. Available at: http://pentaplastspb.ru/pp_pp_pe

- Allahvaisi, S. (2012). Polypropylene in the industry of food packaging. Polypropylene, 978–953.

- Verkhivker, Ya. G., Miroshnychenko, Ye. M. (2020). Сanning food in semi-rigid polymeric and composite containers. Food Science and Technology, 2, 111–118. doi: https://doi.org/10.15673/fst.v14i2.1719

- Krylova, V. B., Gustova, T. V. (2010). Innovatcionnye tekhnologii konservirovaniia produktov pitaniia v polimernoi potrebitelskoi tare. Vse o miase, 1, 4–7.

- Rukovodstvo po razrabotke rezhimov sterilizatcii i pasterizatcii konservov i konservirovannykh polufabrikatov (2011). Moscow: VNIIKOP, 93.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Yakov Verkhivker, Walery Okulicz-Kozaryn, Оlena Myroshnichenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.