Development of a scheme for the distribution of contact areas between the plate and offset cylinders

DOI:

https://doi.org/10.15587/2706-5448.2023.286262Keywords:

actual contact area, roughness, deckle, printing plate, contact zone, micro-protrusions surface roughnessAbstract

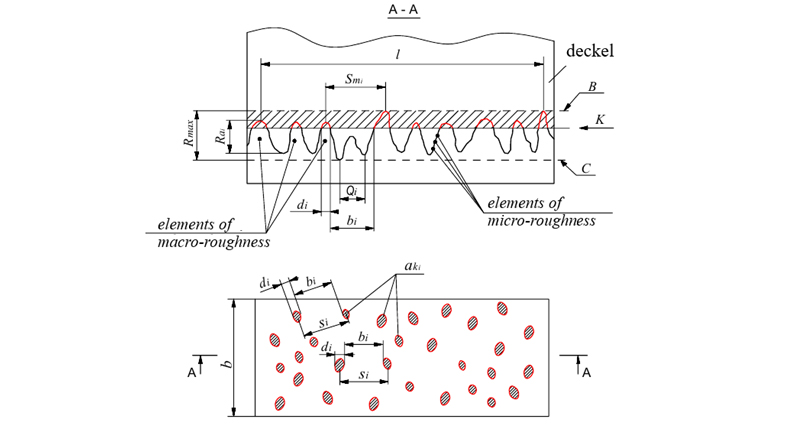

The object of the research is the distribution of contact areas between the plate and offset cylinders. For printing impression in the offset printing process, it is necessary to ensure the transfer of printing ink from the ink unit to the printing plate, from the mold to the rubber-fabric material (deckel) of the offset cylinder and from the deckel to the printed material. At the same time, the quality of the prints is ensured by creating the necessary technological pressure between the plate, offset and printing cylinders, which also contributes to the deformation of the elastic deckel and the transfer of the ink layer in the contact zone. The transfer of illustrative and textual information from the form to the deckel of the offset cylinder occurs due to the actual touch area. Therefore, the study and calculation of the actual contact area is necessary to study the transfer of the paint layer in the contact zones. For this purpose, a review of some studies on contact problems was carried out, their advantages and disadvantages were discussed. Theoretical and experimental relations are given. It has been established that micro protrusions of the surface roughness of the printing plate significantly affect the deformation of the deckel. To study the influence of the surface roughness distribution of the printing plate on the actual deckel contact area in the contact zone, the interaction of micro protrusions of the surface roughness of the printing plate with the deckel surface, leading to additional displacements, was taken into account.

A method for calculating the number of roughness protrusions is proposed to further determine the actual deckel contact area and the actual pressure in the contact zone, taking into account the surface roughness of the printing plate. Based on the parameters calculated by the proposed method with known values of the surface roughness of the printing plate in the future it is possible to determine the actual deckel contact area and the actual contact pressure the optimal values of which are necessary to ensure the required ink transfer and print quality during printing. The data obtained also contribute to the determination of the modes of the printing process when printing the entire circulation, which leads to an increase in the circulation stability of printing forms. Increasing the circulation stability of printing plates allows to save the number of consumed printing plates. In the future, according to the results obtained, it is recommended to compile reference data, which are necessary when setting up and operating the printing machine.

References

- Tiurin, A. A. (1980). Pechatnye mashiny, avtomaty. Moscow: Kniga, 416.

- Wang, J. C., Xing, B. Q., Zhao, T. (2013). Finite Element Analysis on Real Contact Area Based on Fractal Characterization. Key Engineering Materials, 579-580, 517–522. doi: https://doi.org/10.4028/www.scientific.net/kem.579-580.517

- Suslov, M. V. (2010). Diapazon dopustimykh deformatcii tcilindrov pechatnogo apparata. Izvestiia vysshikh uchebnykh zavedenii. Problemy poligrafii i izdatelskogo dela, 4, 41–47.

- Kusaka, Y., Mizukami, M., Yamaguchi, T., Fukuda, N., Ushijima, H. (2019). Patterning defects in high-speed reverse offset printing: lessons from contact dynamics. Journal of Micromechanics and Microengineering, 29 (4). doi: https://doi.org/10.1088/1361-6439/ab024b

- Kim, K., Kim, C. H., Kim, H.-Y., Kim, D.-S. (2010). Effects of Blanket Roller Deformation on Printing Qualities in Gravure-Offset Printing Method. Japanese Journal of Applied Physics, 49 (5S1). doi: https://doi.org/10.1143/jjap.49.05ec04

- Buchner, B., Buchner, M., Buchmayr, B. (2009). Determination of the real contact area for numerical simulation. Tribology International, 42 (6), 897–901. doi: https://doi.org/10.1016/j.triboint.2008.12.009

- Song, B., Yan, S. (2017). Relationship between the real contact area and contact force in pre-sliding regime. Chinese Physics B, 26 (7), 074601. doi: https://doi.org/10.1088/1674-1056/26/7/074601

- Ao, L., Yongming, B., Qifan, C., Guangjun, L. (2019). Fractal Prediction Model for the Contact of Friction Surface and Simulation Analysis. 2019 8th International Conference on Industrial Technology and Management (ICITM), 189–195. doi: https://doi.org/10.1109/icitm.2019.8710745

- Matlin, M. M., Mozgunova, A. I., Kazankina, E. N., Kazankin, V. A. (2014). Calculation of actual area in the contact of a single microasperity modeled by a cone with a smooth surface of the part. Journal of Friction and Wear, 35 (5), 443–447. doi: https://doi.org/10.3103/s1068366614050110

- Matlin, M. M., Mozgunova, A. I., Kazankina, E. N., Kazankin, V. A. (2013). Calculating real area of contact of single microasperity modeled by a cylinder with smooth surface. Journal of Friction and Wear, 34 (5), 391–397. doi: https://doi.org/10.3103/s1068366613050085

- Aliyev, E. A., Khalilov, I. A., Ismailova, Sh. V. (2023). Determination of the actual deckle contact area and the actual pressure in the printed area. Bulletin of the South Ural State University Series «Mechanical Engineering Industry», 23 (1), 40–49. doi: https://doi.org/10.14529/engin230104

- Torskaia, E. V. (2012). Numerical simulation of frictional interaction of a rough indenter and a two-layer elastic half-space. Fizicheskaia mezomekhanika, 15 (2), 31–36.

- Demkin, N. B., Izmailov, V. V. (2010). Zavisimost ekspluatatcionnykh svoistv friktcionnogo kontakta ot mikrogeometrii kontaktiruiushchikh poverkhnostei. Trenie i iznos, 31 (1), 68–77.

- Aliyev, E. A., Khalilov, I. A., Ismailova, Sh. V. (2022). Indirect ink transfer for offset printing, taking into account the roughness of the offset printing plate surface. Machine Science. International scientific-technical journal, 11 (2), 71–79.

- Berkovich, I. I., Gromakovskii, D. G.; Gromakovskii, D. G. (Ed.) (2000). Tribologiia. Fizicheskie osnovy, mekhanika i tekhnicheskie prilozheniia. Samara, 268.

- Kochetkov, A. V., Chvanov, A. V., Arzhanukhina, S. P. (2009). Nauchnye osnovy normirovaniia sherokhovatykh poverkhnostei dorozhnykh pokrytii. Vestnik Volgogradskogo gosudarstvennogo arkhitekturno-stroitelnogo universiteta. Seriia: Stroitelstvo i arkhitektura, 14 (33), 80–86.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Eldar Aliyev, Shebnem Ismailova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.