An effective indicator determination for the leather material uniformity assessment

DOI:

https://doi.org/10.15587/2706-5448.2023.290018Keywords:

deformation properties of leather, strength properties of leather, syntane-tannin composition, filling-plasticization, homogeneity coefficientAbstract

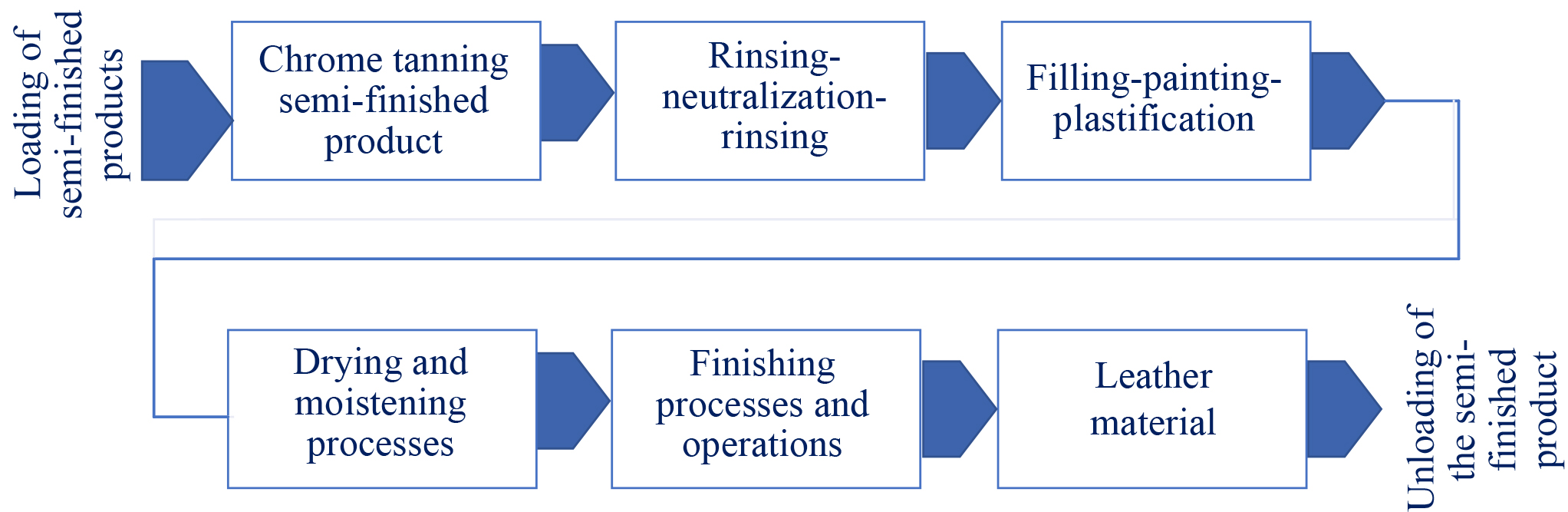

The object of research is the process of determining the objective indicator of the degree of topographic homogeneity of the structure and properties of the leather material. The work defines a set of indicators of properties of semi-finished chrome tanning and leather materials. At the same time, when evaluating the homogeneity of the properties of leather materials, the difference between the values of the physical and mechanical indicators of the shabrack and the bottom is taken into account. At the same time, for a more homogeneous leather material, this difference should be minimal. The maximum differences between the determined physico-mechanical parameters of the semi-finished product of chrome tanning and the minimum for experimental and industrial leather materials were established. The given technological scheme for obtaining an experimental leather material by the technology of syntan-tannin filling-plasticization is more homogeneous with the use of syntan BNS TU 17-06-165-89, mimosa extract with a tannin content of 81.7 %, alkylcarboxyethanolamine of aliphatic acids, dye anionic black K, Fosfol L-1301 emulsions of Cromogenia Units, S.A. (Spain), aluminum potassium alum. For an objective assessment of the homogeneity of the properties of the leather material, a complex indicator is proposed – a coefficient that takes into account the meridian elongation at the crack of the face layer, the limit of strength of the material and its face layer at spherical deformation, which characterize the quality of the leather material according to DSTU 2726-94 «Leather for shoe uppers. Specifications». At the same time, the time-consuming nature of sample preparation and instrumental determination of the properties of leather material is taken into account. The determined complex coefficient of homogeneity of the experimental material is 0.88, and the industrial one is 0.82. This indicates greater homogeneity of the properties of the experimental leather material. A comprehensive analysis and evaluation of the homogeneity of the properties of the experimental leather material testify to the prospects of its use in the manufacture and operation of footwear products.

References

- Heidemann, E. (1995). Überlegungen, wie die Massen von Gerbstoffen und Fetten in der Kollagenstruktur eingelagert werden. Das Leder, 6, 149–154.

- Horbachov, A. A., Kerner, S. M., Andreieva, O. A., Orlova, O. D. (2007). Osnovy stvorennia suchasnykh tekhnolohii vyrobnytstva shkiry ta khutra. Kyiv: Naukova dumka, 190.

- Sathish, M., Subramanian, B., Rao, J. R., Fathima, N. N. (2019). Deciphering the role of individual retanning agents on physical properties of leathers. JALCA, 114 (3), 94–102.

- Xie, H., Sun, Q., Liao, X., Shi, B. (2014). Melamine glyoxal resinasare tanning agent – Preparation and application. Journal of the Society of Leather Technologists and Chemists, 98 (1), 17–22.

- Jin, L. Q., Wang, Y. L., Zhu, D. Y., Xu, Q. H. (2011). Effect of Amphoteric Acrylic Retanning Agent on the Physical Properties of the Resultant Leather. Advanced Materials Research, 284-286, 1925–1928. doi: https://doi.org/10.4028/www.scientific.net/amr.284-286.1925

- Zeng, Y., Song, Y., Li, J., Zhang, W., Shi, B. (2016). Visualization and Quantification of Penetration. Mass Transfer of Acrylic Resin Retanning Agent in Leather using Florescent-Tracing Technique. JALCA, 111 (11), 398–405.

- Sun, X., Jin, Y., Lai, S., Pan, J., Du, W., Shi, L. (2018). Desirable retanning system for aldehyde-tanned leather to reduce the formaldehyde content and improve the physical-mechanical properties. Journal of Cleaner Production, 175, 199–206. doi: https://doi.org/10.1016/j.jclepro.2017.12.058

- Zhang, P., Xu, P., Fan, H., Zhang, Z., Chen, Y. (2018). Phosphorusnitrogen flame retardant waterborne polyurethane/graphene nanocomposite for leather retanning. JALCA, 113 (5), 142–150.

- Li, C., Taotao, Q., Li, X., Longfang, R., Xuechuan, W. (2017). Preparation and application of collagen-based water borne polyurethane retanning agent. Journal of the Society of Leather Technologists and Chemists, 101 (3), 149–154.

- Hlubish, P. A., Teslia, O. P., Kerner, O. M., Kistechko, I. M., Dmytryshyna, I. V., Vitushko, N. V. (2018). Pat. 33051 UA. Sklad dlia dodublennia-napovnennia shkir. MPK S14S 3/00, S14S 9/00; No. u200801313; declareted: 04.02.2018; published: 10.06.2018, Bul. No. 24.

- Zarlok, J., Kowalska, M., Smiechowski, K. (2017). Effect of the type of retanning on hygienic properties of crust leathers. Journal of the Society of Leather Technologists and Chemists, 101 (1), 21–26.

- Danylkovych, A. H. (2006). Praktykum z khimii i tekhnolohii shkiry ta khutra. Kyiv: Feniks, 340.

- Iagoda, L. A., Ostrovskii, V. S. (1978). Pribor i metodika ispytanii kozhi. KOP, 7, 52–55.

- DSTU 2726-94. Shkira dlia verkhu vzuttia. Tekhnichni umovy (1995). Kyiv: Derzhstandart Ukrainy, 14.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Аnatolii Danylkovych, Olga Sanginova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.