Development of method for managing risk factors for emergency situations when using low-sulfur content fuel in marine diesel engines

DOI:

https://doi.org/10.15587/2706-5448.2023.290198Keywords:

emergency situation, dynamic loads, environmental indicators, management method, sea transport, marine diesel, heat loads, risk factorAbstract

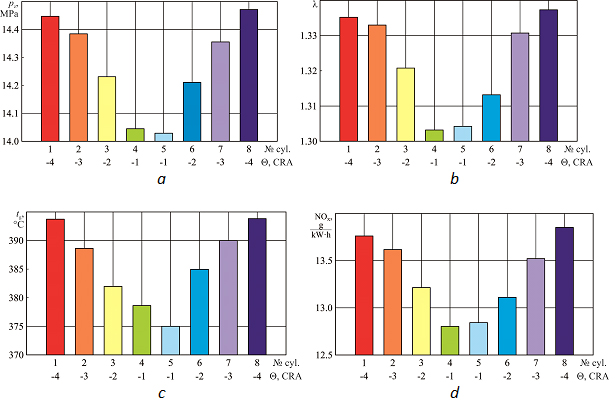

The operation process of marine diesel engines when using fuel with a sulfur content of no more than 0.1 % was chosen as the object of the study. Similar types of fuel are characterized by a lower auto-ignition temperature and higher calorific value. During combustion, this leads to an increase in the rate of fuel combustion and the degree of pressure increase during combustion, precisely because of this, the dynamic loads on the parts of the cylinder-piston group and diesel engine bearings increase. Also, this (due to the increase in temperature at the end of combustion) creates conditions for an increase in the concentration of nitrogen oxides in diesel exhaust gases. This (namely, the change in dynamic and thermal loads that occur during the use of fuels with a reduced sulfur content in marine diesel engines) leads to the occurrence of emergency situations. As a method of managing the risk of such emergency situations, the reconfiguration of the high-pressure fuel equipment, namely the change of the advance angles of the fuel supply, is proposed. The research was carried out on a vessel intended for the transportation of containers and on which a marine diesel engine 8K80ME-8.2-TII MAN-Diesel & Turbo was installed as the main engine. Combustion pressure, the degree of pressure increase during combustion, the temperature of exhaust gases, and the concentration of nitrogen oxides in exhaust gases were chosen as the indicators for evaluating the use and implementation of the proposed method. It has been experimentally proven that this results in an increase in the environmental sustainability of diesel operation by 3.61–10.97 %, an increase in thermal stability – up to 2.54 %, and an increase in dynamic stability – up to 4.82 %. This is due to the shift of the self-ignition and combustion process towards expansion and the corresponding decrease in pressure and temperature at the end of combustion. The most favorable use of this method is on modern diesel engines that have an electronic fuel injection control system, so they do not require mechanical reconfiguration of fuel pumps. Taking this into account, the method based on the change of fuel advance angles is defined as the one that provides management of the risk factors of emergency situations when using low-sulfur fuel in marine diesel engines.

References

- Maryanov, D. (2021). Development of a method for maintaining the performance of drilling fluids during transportation by Platform Supply Vessel. Technology Audit and Production Reserves, 5 (2 (61)), 15–20. doi: https://doi.org/10.15587/2706-5448.2021.239437

- Turpak, S. M., Taran, I. O., Fomin, O. V., Tretiak, O. O. (2018). Logistic technology to deliver raw material for metallurgical production. Scientific Bulletin of National Mining University, 1, 162–169. doi: https://doi.org/10.29202/nvngu/2018-1/3

- Fomin, O., Lovska, A., Skok, P., Rogovskii, I. (2021). Determination of the dynamic load of the carrying structure of the hopper wagon with the actual dimensions of structural elements. Technology Audit and Production Reserves, 1 (1 (57)), 6–11. doi: https://doi.org/10.15587/2706-5448.2021.225458

- Vorokhobin, I., Burmaka, I., Fusar, I., Burmaka, O. (2022). Simulation Modeling for Evaluation of Efficiency of Observed Ship Coordinates. TransNav, the International Journal on Marine Navigation and Safety of Sea Transportation, 16 (1), 137–141. doi: https://doi.org/10.12716/1001.16.01.15

- Sagin, S. V., Sagin, S. S., Madey, V. (2023). Analysis of methods of managing the environmental safety of the navigation passage of ships of maritime transport. Technology Audit and Production Reserves, 4 (3 (72)), 33–42. doi: https://doi.org/10.15587/2706-5448.2023.286039

- Madey, V. V. (2021). Usage of biodiesel in marine diesel engines. The Austrian Journal of Technical and Natural Sciences, 7-8, 18–21. doi: https://doi.org/10.29013/ajt-21-7.8-18-21

- Chu Van, T., Ramirez, J., Rainey, T., Ristovski, Z., Brown, R. J. (2019). Global impacts of recent IMO regulations on marine fuel oil refining processes and ship emissions. Transportation Research Part D: Transport and Environment, 70, 123–134. doi: https://doi.org/10.1016/j.trd.2019.04.001

- Sagin, S., Kuropyatnyk, O., Sagin, A., Tkachenko, I., Fomin, O., Píštěk, V., Kučera, P. (2022). Ensuring the Environmental Friendliness of Drillships during Their Operation in Special Ecological Regions of Northern Europe. Journal of Marine Science and Engineering, 10 (9), 1331. doi: https://doi.org/10.3390/jmse10091331

- Puškár, M., Tarbajovský, P., Lavčák, M., Šoltésová, M. (2022). Marine Ancillary Diesel Engine Emissions Reduction Using Advanced Fuels. Journal of Marine Science and Engineering, 10 (12), 1895. doi: https://doi.org/10.3390/jmse10121895

- Ershov, M. A., Savelenko, V. D., Makhmudova, A. E., Rekhletskaya, E. S., Makhova, U. A., Kapustin, V. M. et al. (2022). Technological Potential Analysis and Vacant Technology Forecasting in Properties and Composition of Low-Sulfur Marine Fuel Oil (VLSFO and ULSFO) Bunkered in Key World Ports. Journal of Marine Science and Engineering, 10 (12), 1828. doi: https://doi.org/10.3390/jmse10121828

- Kuropyatnyk, O. A. (2020). Reducing the emission of nitrogen oxides from marine diesel engines. Scientific research of the SCO countries: synergy and integration, 154–160. doi: https://doi.org/10.34660/INF.2020.24.53689

- Sagin, S. V., Kuropyatnyk, O. A. (2018). The Use of Exhaust Gas Recirculation for Ensuring the Environmental Performance of Marine Diesel Engines. Naše More, 65 (2), 78–86. doi: https://doi.org/10.17818/nm/2018/2.3

- Madey, V. (2022). Assessment of the efficiency of biofuel use in the operation of marine diesel engines. Technology Audit and Production Reserves, 2 (1 (64)), 34–41. doi: https://doi.org/10.15587/2706-5448.2022.255959

- Akimova, O., Kravchenko, A. (2018). Development of the methodology of the choice of the route of work of platform supply vessels in the shelf of the seas. Technology Audit and Production Reserves, 5 (2 (43)), 30–35. doi: https://doi.org/10.15587/2312-8372.2018.146322

- Salova, T., Lekomtsev, P., Likhanov, V., Lopatin, O., Belov, E. (2023). Development of calculation methods and optimization of working processes of heat engines. AIP Conference Proceedings. doi: https://doi.org/10.1063/5.0137793

- Minchev, D. S., Varbanets, R. A., Alexandrovskaya, N. I., Pisintsaly, L. V. (2021). Marine diesel engines operating cycle simulation for diagnostics issues. Acta Polytechnica, 61 (3), 435–447. doi: https://doi.org/10.14311/ap.2021.61.0435

- Maryanov, D. (2022). Control and regulation of the density of technical fluids during their transportation by sea specialized vessels. Technology Audit and Production Reserves, 1 (2 (63)), 19–25. doi: https://doi.org/10.15587/2706-5448.2022.252336

- Melnyk, O., Onyshchenko, S., Onishchenko, O. (2023). Development measures to enhance the ecological safety of ships and reduce operational pollution to the environment. Scientific Journal of Silesian University of Technology. Series Transport, 118, 195–206. doi: https://doi.org/10.20858/sjsutst.2023.118.13

- Gorb, S., Budurov, M. (2021). Increasing the Accuracy of a Marine Diesel Engine Operation Limit by Thermal Factor. International Review of Mechanical Engineering, 15 (3), 115–121. doi: https://doi.org/10.15866/ireme.v15i3.20865

- Varbanets, R., Fomin, O., Píštěk, V., Klymenko, V., Minchev, D., Khrulev, A. et al. (2021). Acoustic Method for Estimation of Marine Low-Speed Engine Turbocharger Parameters. Journal of Marine Science and Engineering, 9 (3), 321. doi: https://doi.org/10.3390/jmse9030321

- Sagin, S. V. (2019). Decrease in mechanical losses in high-pressure fuel equipment of marine diesel engines. Scientific research of the SCO countries: synergy and integration. Part 1, 139–145. doi: https://doi.org/10.34660/INF.2019.15.36258

- Maryanov, D. (2022). Reduced energy losses during transportation of drilling fluid by Platform Supply Vessels. Technology Audit and Production Reserves, 2 (1 (64)), 42–50. doi: https://doi.org/10.15587/2706-5448.2022.256473

- Sagin, S., Madey, V., Stoliaryk, T. (2021). Analysis of mechanical energy losses in marine diesels. Technology Audit and Production Reserves, 5 (2 (61)), 26–32. doi: https://doi.org/10.15587/2706-5448.2021.239698

- Sagin, S., Madey, V., Sagin, A., Stoliaryk, T., Fomin, O., Kučera, P. (2022). Ensuring Reliable and Safe Operation of Trunk Diesel Engines of Marine Transport Vessels. Journal of Marine Science and Engineering, 10 (10), 1373. doi: https://doi.org/10.3390/jmse10101373

- Öztürk, E., Can, Ö. (2022). Effects of EGR, injection retardation and ethanol addition on combustion, performance and emissions of a DI diesel engine fueled with canola biodiesel/diesel fuel blend. Energy, 244, 123129. doi: https://doi.org/10.1016/j.energy.2022.123129

- Sagin, S. V., Kuropyatnyk, O. A., Zablotskyi, Y. V., Gaichenia, O. V. (2022). Supplying of Marine Diesel Engine Ecological Parameters. Naše More, 69 (1), 53–61. doi: https://doi.org/10.17818/nm/2022/1.7

- Sagin, S. V., Kuropyatnyk, O. A. (2021). Using exhaust gas bypass for achieving the environmental performance of marine diesel engines. The Austrian Journal of Technical and Natural Sciences, 7-8, 36–43. doi: https://doi.org/10.29013/ajt-21-7.8-36-43

- Melnyk, O., Onyshchenko, S., Onishchenko, O., Lohinov, O., Ocheretna, V. (2023). Integral Approach to Vulnerability Assessment of Ship’s Critical Equipment and Systems. Transactions on Maritime Science, 12 (1). doi: https://doi.org/10.7225/toms.v12.n01.002

- Burmaka, I., Vorokhobin, M., Vorokhobin, I., Zhuravska, I. (2022). Forming the area of unacceptable values of the parameters of vessels’ movement for the vessels’ divergence at remote control process. Acta Innovations, 44, 5–17. doi: https://doi.org/10.32933/actainnovations.44.1

- Cherniak, L., Varshavets, P., Dorogan, N. (2017). Development of a mineral binding material with elevated content of red mud. Technology Audit and Production Reserves, 3 (3 (35)), 22–28. doi: https://doi.org/10.15587/2312-8372.2017.105609

- Sagin, S. V. (2020). Determination of the optimal recovery time of the rheological characteristics of marine diesel engine lubricating oils. Process Management and Scientific Developments, Part 4, 195–202. doi: https://doi.org/10.34660/INF.2020.4.52991

- Sagin, S. V., Stoliaryk, T. O. (2021). Comparative assessment of marine diesel engine oils. The Austrian Journal of Technical and Natural Sciences, 7-8, 29–35. doi: https://doi.org/10.29013/ajt-21-7.8-29-35

- Stoliaryk, T. (2022). Analysis of the operation of marine diesel engines when using engine oils with different structural characteristics. Technology Audit and Production Reserves, 5 (1 (67)), 22–32. doi: https://doi.org/10.15587/2706-5448.2022.265868

- Sagin, S., Karianskyi, S., Madey, V., Sagin, A., Stoliaryk, T., Tkachenko, I. (2023). Impact of Biofuel on the Environmental and Economic Performance of Marine Diesel Engines. Journal of Marine Science and Engineering, 11 (1), 120. doi: https://doi.org/10.3390/jmse11010120

- Vedachalam, S., Baquerizo, N., Dalai, A. K. (2022). Review on impacts of low sulfur regulations on marine fuels and compliance options. Fuel, 310, 122243. doi: https://doi.org/10.1016/j.fuel.2021.122243

- Zhu, J., Zhou, D., Yang, W., Qian, Y., Mao, Y., Lu, X. (2023). Investigation on the potential of using carbon-free ammonia in large two-stroke marine engines by dual-fuel combustion strategy. Energy, 263, 125748. doi: https://doi.org/10.1016/j.energy.2022.125748

- Wang, X., Zhu, J., Han, M. (2023). Industrial Development Status and Prospects of the Marine Fuel Cell: A Review. Journal of Marine Science and Engineering, 11 (2), 238. doi: https://doi.org/10.3390/jmse11020238

- Winnes, H., Fridell, E., Moldanová, J. (2020). Effects of Marine Exhaust Gas Scrubbers on Gas and Particle Emissions. Journal of Marine Science and Engineering, 8 (4), 299. doi: https://doi.org/10.3390/jmse8040299

- Shu, Z., Gan, H., Ji, Z., Liu, B. (2022). Modeling and Optimization of Fuel-Mode Switching and Control Systems for Marine Dual-Fuel Engine. Journal of Marine Science and Engineering, 10 (12), 2004. doi: https://doi.org/10.3390/jmse10122004

- Sultanbekov, R., Denisov, K., Zhurkevich, A., Islamov, S. (2022). Reduction of Sulphur in Marine Residual Fuels by Deasphalting to Produce VLSFO. Journal of Marine Science and Engineering, 10 (11), 1765. doi: https://doi.org/10.3390/jmse10111765

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Sergii Sagin, Arsenii Sagin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.