Analysis of refrigerants used in supermarket commercial equipment and the potential for increasing energy efficiency and reducing environmental impact

DOI:

https://doi.org/10.15587/2706-5448.2024.307323Keywords:

propane, isobutane, refrigerant, hydrocarbons and their mixtures, fire hazard, commercial refrigeration equipmentAbstract

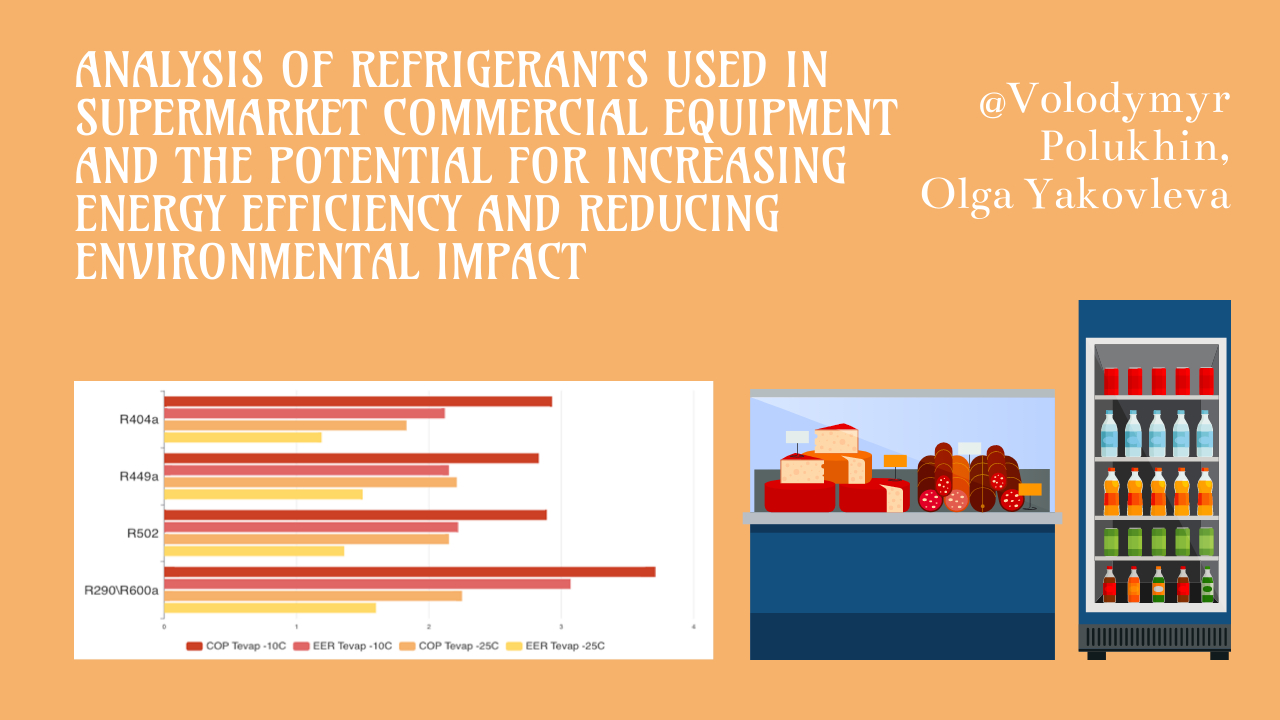

Refrigerants used in the commercial equipment of supermarkets are the object of the research. The Montreal Protocol calls for a complete phase-out of hydrochlorofluorocarbons (HCFCs) by 2030, and the Kigali Amendment regulates the use of hydrofluorocarbons (HFCs) from 2019. Developed countries began phasing out HFC use in 2019, while developing countries plan to freeze HFC consumption from 2024. These global efforts are aimed at reducing the depletion of the ozone layer and combating climate change. The number of supermarkets in the world varies greatly: in Europe they number from 110 thousand to 115 thousand, and in China – from 65 thousand to 70 thousand, which reflects various needs in refrigeration equipment. Stringent environmental regulations are forcing the commercial refrigeration sector to remain globally competitive. Modernization of supermarkets using natural refrigerants is important for solving emerging challenges. The results of the study show significant improvements in energy efficiency ratio (EER) and coefficient of performance (COP) when using a mixture of hydrocarbons (R290: 85 %, R600a: 15 %) compared to traditional refrigerants R404a, R449a and R502. Specifically, at the evaporation temperature of Tevap=–10 °C, EER increased by 38–44 % and COP by 26–31 % compared to R404a and R449a, respectively. At Tevap=–25 °C, EER increased by 17–34 % and COP by 2–22 % compared to R404a and R449a. Additionally, compared to R502, the hydrocarbon blend showed a 38–44 % increase in EER and 28–31 % COP at Tevap=–10 °C, and a 17–34 % increase in EER and 5–22 % COP at Tevap=–25 °C. These results highlight the advantages of the hydrocarbon mixture at different evaporation temperatures, indicating its potential to improve energy efficiency in refrigeration applications. The obtained data suggest the possibility of a wider application of the mixture of hydrocarbons in commercial refrigeration plants, offering both improved performance and compliance with safety regulations.

References

- About Montreal Protocol. UN Environment Programme. Available at: https://www.unep.org/ozonaction/who-we-are/about-montreal-protocol

- Amendment to the Montreal Protocol on Substances that Deplete the Ozone Layer (2016). United Nations Treaty Collection. Available at: https://treaties.un.org/Pages/ViewDetails.aspx?src=IND&mtdsg_no=XXVII-2-f&chapter=27&clang=_en

- EU-Rules. Guidance on the EU's F-gas Regulation and its legal framework. European Commission. Available at: https://climate.ec.europa.eu/eu-action/fluorinated-greenhouse-gases/eu-rules_en

- Summary of the Clean Air Act. United States Environmental Protection Agency. Available at: https://www.epa.gov/laws-regulations/summary-clean-air-act

- Hisashima, S. (2003). Fluorocarbon recovery and destruction: legislation. Refrigeration, 78 (904). Available at: https://iifiir.org/en/fridoc/fluorocarbon-recovery-and-destruction-legislation-120757

- Foster, A., Evans, J., Maidment, G. (2018). Benchmarking of Supermarket Energy Consumption. 5th IIR International Conference on Sustainability and the Cold Chain. Beijing. doi: https://doi.org/10.18462/iir.iccc.2018.0006

- Yakovleva, O. Y., Khmelniuk, M. G., Ostapenko, O. V. (2018). Energy efficiency projects. Refrigeration Engineering and Technology, 54 (2), 25–29. doi: https://doi.org/10.15673/ret.v54i2.1099

- Morrison, O. (2023). Inside the ‘Supermarket of the Future’ Promising to Waste Less Energy and Less Food. FoodNavigator. Available at: https://www.foodnavigator.com/Article/2023/06/30/Inside-the-supermarket-of-the-future-promising-to-waste-less-energy-and-less-food

- BS EN 60335-2-89:2010+A2:2017. Household and Similar Electrical Appliances. Safety Particular Requirements for Commercial Refrigerating Appliances with an Incorporated or Remote Refrigerant Unit or Compressor. European Standard. Available at: https://www.en-standard.eu/bs-en-60335-2-89-2010-a2-2017-household-and-similar-electrical-appliances-safety-particular-requirements-for-commercial-refrigerating-appliances-with-an-incorporated-or-remote-refrigerant-unit-or-compressor/?gad_source=1&gclid=Cj0KCQjwjLGyBhCYARIsAPqTz1_1-CDsqY_nRdtye2HU2x-2Sb6EhkFxs50fWF9xbHFXVEKJtlfQ2w8aAoJDEALw_wcB

- F-Gas regulation (2022). IIR. Available at: https://iifiir.org/en/news/latest-news-about-regulation-in-europe

- Energy Efficiency 2023. International energy agency. Available at: https://iea.blob.core.windows.net/assets/dfd9134f-12eb-4045-9789-9d6ab8d9fbf4/EnergyEfficiency2023.pdf

- Food security (2022). Climate Change and Land, 437–550. doi: https://doi.org/10.1017/9781009157988.007

- ISO 5149-1:2014(en). Refrigerating systems and heat pumps – Safety and environmental requirements – Part 1: Definitions, classification and selection criteria. ISO. Available at: https://www.iso.org/obp/ui#iso:std:iso:5149:-1:ed-1:v1:en

- ISO 5149-2:2014(en). Refrigerating systems and heat pumps – Safety and environmental requirements – Part 2: Design, construction, testing, marking and documentation. ISO. Available at: https://www.iso.org/obp/ui#iso:std:iso:5149:-2:ed-1:v1:en

- ISO 5149-3:2014(en). Refrigerating systems and heat pumps – Safety and environmental requirements – Part 3: Installation site. ISO. Available at: https://www.iso.org/obp/ui#iso:std:iso:5149:-3:ed-1:v1:en

- Global Hydrocarbons Market – Industry Trends and Forecast to 2030. DataBridge. Available at: https://www.databridgemarketresearch.com/reports/global-hydrocarbons-market

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Volodymyr Polukhin, Olga Yakovleva

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.