Determination of the possibilities of using the universal low-temperature rotary apparatus for the production of meat and vegetable products under the conditions of providing uniform heat supply

DOI:

https://doi.org/10.15587/2706-5448.2024.307332Keywords:

low-temperature rotary apparatus, meat-vegetable product, polycomponent vegetable semi-finished products, temperature fieldAbstract

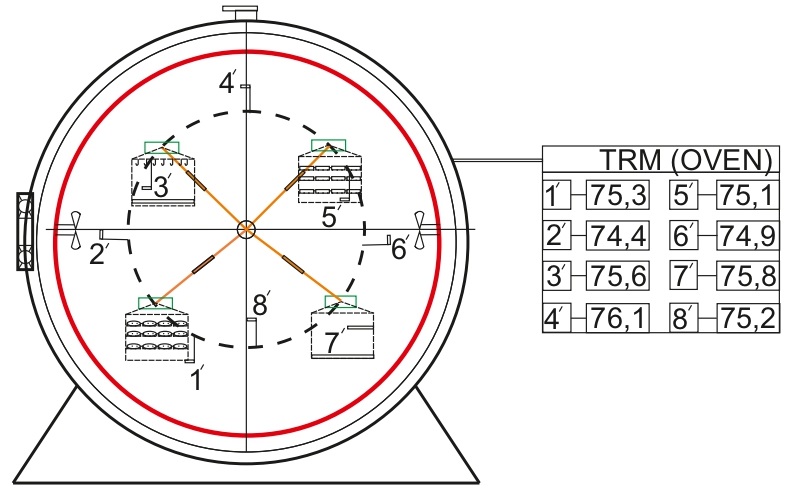

The object of research is the process of frying a meat-vegetable product in the developed universal low-temperature rotary apparatus. The problem of ensuring the uniformity of the temperature field during low-temperature processing of meat and vegetable products is solved in the developed universal low-temperature rotary apparatus. The expected effect during the approbation of the apparatus is predicted under the condition of eliminating high-temperature intermediate coolants (hot air, etc.) due to the use of a film-like resistive electronic heater of the radiating type. The temperature field is established, which confirms the uniformity of the temperature effect on meat and vegetable products, and a slight deviation within the limits of autonomous exhaust fans is not critical and within the permissible error. Also, the introduction of Peltier elements into the design of the rotary apparatus will allow converting thermal energy into a low-voltage supply voltage (3–6 W) and, already at 20 °C, ensure autonomous operation of fans. The obtained results in the form of practical implementation of the developed apparatus will allow to implement low-temperature processing of meat and vegetable products. This allows to maximally preserve the functional properties of meat raw materials and the physiological properties of vegetable semi-finished products with a high degree of readiness.

The practical implementation of the universal low-temperature rotary apparatus from the side of constructive implementation due to the use of functional containers makes it possible to obtain a wide range of assortment of meat products, both in the shell and without the shell. The elimination of high-temperature intermediate heat carriers (hot air, steam, etc.), their technical networks and generating apparatuss ensures energy and metal-intensive resource savings. In addition, the introduction of multicomponent vegetable semi-finished products of a high degree of readiness (powders, pastes, etc.) into the recipes of meat products will lead to a partial replacement of the main recipe components and an increase in the functional properties of the finished products.

References

- Proizvodstvo vetchiny. Piat osnovnykh etapov (2016). Available at: https://foodbay.com/wiki/masnaja-industrija/2016/06/10/proizvodstvo-vetchiny-pyat-osnovnyh-etapov/

- Pankova, N. V. (2012). Innovatcionnye tekhnologii v oblasti pishchevykh produktov i produktcii obshchestvennogo pitaniia funktcionalnogo i spetcializirovannogo naznacheniia. Saint Petersburg: Izd-vo «LEMA», 314.

- Dominguez-Hernandez, E., Salaseviciene, A., Ertbjerg, P. (2018). Low-temperature long-time cooking of meat: Eating quality and underlying mechanisms. Meat Science, 143, 104–113. doi: https://doi.org/10.1016/j.meatsci.2018.04.032

- Vujadinović, D., Marjanović-Balaban, Ž. (2012). Influence of Temperature and Heat Treatment Regime on Chemical Properties of Pork Meat. Quality of Life (Banja Luka) – APEIRON, 6 (3-4), 49–54. doi: https://doi.org/10.7251/qol1203049v

- Halagarda, M., Wójciak, K. M. (2022). Health and safety aspects of traditional European meat products. A review. Meat Science, 184, 108623. doi: https://doi.org/10.1016/j.meatsci.2021.108623

- Park, C. H., Lee, B., Oh, E., Kim, Y. S., Choi, Y. M. (2020). Combined effects of sous-vide cooking conditions on meat and sensory quality characteristics of chicken breast meat. Poultry Science, 99 (6), 3286–3291. doi: https://doi.org/10.1016/j.psj.2020.03.004

- Zahorulko, A., Zagorulko, A., Yancheva, M., Serik, M., Sabadash, S., Savchenko-Pererva, M. (2019). Development of the plant for low-temperature treatment of meat products using ir-radiation. Eastern-European Journal of Enterprise Technologies, 1 (11 (97)), 17–22. doi: https://doi.org/10.15587/1729-4061.2019.154950

- Ruiz-Carrascal, J., Roldan, M., Refolio, F., Perez-Palacios, T., Antequera, T. (2019). Sous-vide cooking of meat: A Maillarized approach. International Journal of Gastronomy and Food Science, 16, 100138. doi: https://doi.org/10.1016/j.ijgfs.2019.100138

- da Silva, F. L. F., de Lima, J. P. S., Melo, L. S., da Silva, Y. S. M., Gouveia, S. T., Lopes, G. S., Matos, W. O. (2017). Comparison between boiling and vacuum cooking ( sous-vide ) in the bioaccessibility of minerals in bovine liver samples. Food Research International, 100, 566–571. doi: https://doi.org/10.1016/j.foodres.2017.07.054

- Zahorulko, O. Ye., Zahorulko, A. M. (2016). Pat. No. 108041 UA. Hnuchkyi plivkovyi rezystyvnyi elektronahrivach vyprominiuiuchoho typu. MPK: G05D 23/19, B01D 1/22, H05B 3/36. No. u201600827; declareted: 02.02.2016; published: 24.06.2016, Bul. No. 12, 4. Available at: http://uapatents.com/5-108041-gnuchkijj-plivkovijj-rezistivnijj-elektronagrivach-viprominyuyuchogo-tipu.html

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Andrii Zahorulko, Aleksey Zagorulko, Nataliia Tytarenko, Eldar Ibaiev, Vitaly Zahorulko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.