Reducing the risk of air pollution in working areas by construction dust using a combined dust collector

DOI:

https://doi.org/10.15587/2706-5448.2025.325775Keywords:

air purification, combined dust collector, differential distribution curve, non-carcinogenic risk, dust removal systemsAbstract

The object of research is methods for reducing the level of air pollution in working areas with industrial dust. The problem of reducing the impact of dustiness of production premises on the workers' health is solved by improving the aspiration air purification system.

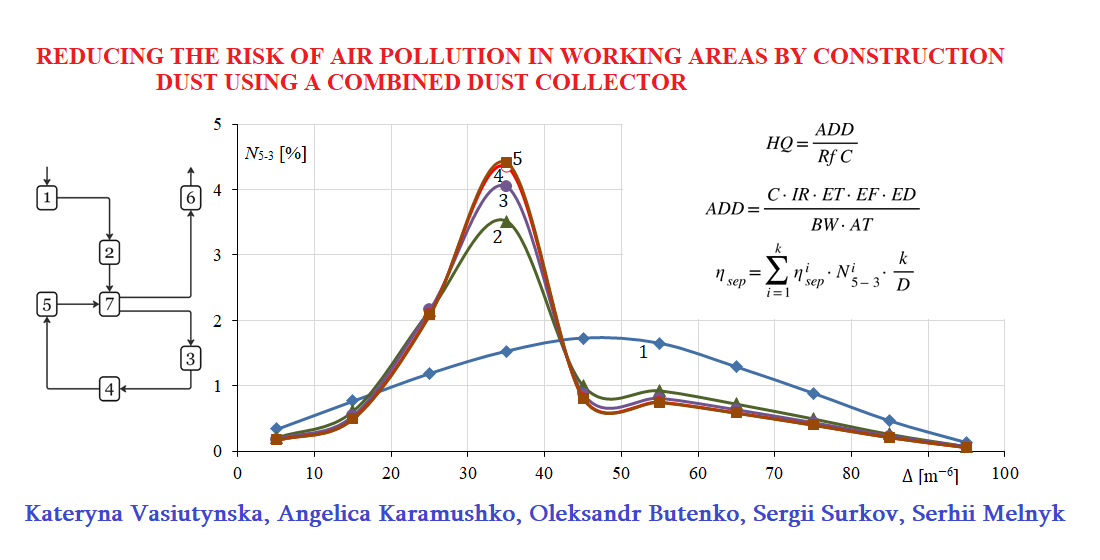

A new approach is proposed that provides the blower (fan) with an additional purification function by attaching a dust collector to its housing. By organizing the circulation movement of the dust-gas flow, part of the dust settles in the dust collector before it enters the main dust collector. Such a combined dust collector can be used as an independent device in closed aspiration systems or as part of complex dust removal systems, reducing the load on the main device. A methodology for calculating purification indicators has been developed, which is based on the discretization of the differential dust mass distribution curve by particle size. The method allows to assess the efficiency of the process, determine the dimensions of the dust collection container and the frequency of dust discharge from it. The technology was used for the air aspiration system of the working area of the building materials processing facility to reduce the risk to workers' health from air pollution. The calculations have established the conditions of acceptable non-carcinogenic risk at the level of construction dust concentration not higher than 61.42 mg/m3, and with the introduction of the proposed combined dust collector, it is possible to increase the dust level to 99.1 mg/m³ without exceeding the risk threshold.

The proposed technology is cost-effective, requires minimal design changes and can be implemented at most industrial facilities, especially in conditions of high dustiness of production premises.

References

- Brauer, M., Brook, J. R., Christidis, T., Chu, Y., Crouse, D. L., Erickson, A. et al. (2019). Mortality–air pollution associations in low-exposure environments (MAPLE): phase 1. Research Reports: Health Effects Institute. Available at: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7334864/

- Brauer, M., Brook, J. R., Christidis, T., Chu, Y., Crouse, D. L., Erickson, A., et al. (2022). Mortality–air pollution associations in low exposure environments (MAPLE): Phase 2. Research Reports: Health Effects Institute. Available at: https://pubmed.ncbi.nlm.nih.gov/36224709/

- Li, C. Z., Zhao, Y., Xu, X. (2019). Investigation of dust exposure and control practices in the construction industry: Implications for cleaner production. Journal of Cleaner Production, 227, 810–824. https://doi.org/10.1016/j.jclepro.2019.04.174

- Wang, M., Yao, G., Sun, Y., Yang, Y., Deng, R. (2023). Exposure to construction dust and health impacts – A review. Chemosphere, 311, 136990. https://doi.org/10.1016/j.chemosphere.2022.136990

- Miller, B. G. (2010). Advanced flue gas dedusting systems and filters for ash and particulate emissions control in power plants. Advanced Power Plant Materials, Design and Technology. Woodhead Publishing, 217–243. https://doi.org/10.1533/9781845699468.2.217

- Omine, M., Nagayasu, T., Ishizaka, H., Miyake, K., Orita, K., Kagawa, S. (2017). AQCS (air quality control system) for thermal power plants capable of responding to wide range of coal properties and regulations. Mitsubishi Heavy Industries Technical Review, 54 (3), 55‒62. Available at: https://www.mhps.com/jp/randd/technical-review/pdf/index_44e.pdf

- Ng, B. F., Xiong, J. W., Wan, M. P. (2017). Application of acoustic agglomeration to enhance air filtration efficiency in air-conditioning and mechanical ventilation (ACMV) systems. PLOS ONE, 12 (6), e0178851. https://doi.org/10.1371/journal.pone.0178851

- Yan, J., Chen, L., Yang, L. (2016). Combined effect of acoustic agglomeration and vapor condensation on fine particles removal. Chemical Engineering Journal, 290, 319–327. https://doi.org/10.1016/j.cej.2016.01.075

- Ono, Y., Asami, T., Miura, H. (2023). Agglomeration of aerosol using small equipment with two small aerial ultrasonic sources. Japanese Journal of Applied Physics, 62 (SJ), SJ1029. https://doi.org/10.35848/1347-4065/acbbd3

- Riera, E., González-Gómez, I., Rodríguez, G., Gallego-Juárez, J. A. (2023). Ultrasonic agglomeration and preconditioning of aerosol particles for environmental and other applications. Power Ultrasonics. Elsevier, 861–886. https://doi.org/10.1016/b978-0-12-820254-8.00029-4

- Hoda, Y., Asami, T., Miura, H. (2022). Aerosol agglomeration by aerial ultrasonic sources containing a cylindrical vibrating plate with the same diameter as a circular tube. Japanese Journal of Applied Physics, 61 (SG), SG1073. https://doi.org/10.35848/1347-4065/ac55db

- Madani, M. (2023). Protection of the atmosphere of urbanized areas from dust emissions during the manufacture of aerated concrete structures. Technogenic and Ecological Safety, 13 (1/2023), 11–19. https://doi.org/10.52363/2522-1892.2023.1.2

- Afshari, A., Ekberg, L., Forejt, L., Mo, J., Rahimi, S., Siegel, J. et al. (2020). Electrostatic Precipitators as an Indoor Air Cleaner – A Literature Review. Sustainability, 12 (21), 8774. https://doi.org/10.3390/su12218774

- Muzafarov, S., Tursunov, O., Balitskiy, V., Babayev, A., Batirova, L., Kodirov, D. (2020). Improving the efficiency of electrostatic precipitators. International Journal of Energy for a Clean Environment, 21 (2), 125–144. https://doi.org/10.1615/interjenercleanenv.2020034379

- Klymets, V. V., Kozyra, I. M. (2013). Stvorennia pryntsypovo novykh konstruktsii aparativ dlia vlovlennia pylu, shcho nalypaie. Informatsiini tekhnolohii: nauka, tekhnika, tekhnolohiia, osvita, zdorovia. Kharkiv, 324.

- Butenko, O., Vasiutynska, K., Smyk, S. (2018). Development of double-circuit closed-loop dedusting system for increasing the atmosphere safety level. Odes’kyi Politechnichnyi Universytet Pratsi, 3 (56), 102–108. https://doi.org/10.15276/opu.3.56.2018.11

- Zhou, D., Luo, Z., Jiang, J., Chen, H., Lu, M., Fang, M. (2016). Experimental study on improving the efficiency of dust removers by using acoustic agglomeration as pretreatment. Powder Technology, 289, 52–59. https://doi.org/10.1016/j.powtec.2015.11.009

- Larki, I., Zahedi, A., Asadi, M., Forootan, M. M., Farajollahi, M., Ahmadi, R., Ahmadi, A. (2023). Mitigation approaches and techniques for combustion power plants flue gas emissions: A comprehensive review. Science of The Total Environment, 903, 166108. https://doi.org/10.1016/j.scitotenv.2023.166108

- Hlushchenko, O. L., Litvinov, M. P. (2023). Development of the flue gas cleaning system of boiler units operating on solid fuel. Modern Engineering and Innovative Technologies, 1 (26-01), 37–43. https://doi.org/10.30890/2567-5273.2023-26-01-051

- Butenko, O., Vasiutynska, K., Smyk, S., Karamushko, A. (2024). Basics of calculation of a two-circuit air purification system for polydisperse dust. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, 2, 113–119. https://doi.org/10.33271/nvngu/2024-2/113

- Otsinka ryzykiv dlia zdorovia pratsivnykiv vid zabrudnennia povitria robochoi zony khimichnymy rechovynamy (2024). Nakaz MOZ Ukrainy No. 358. 02.03.2024. Available at: https://zakon.rada.gov.ua/rada/show/v0358282-24#Text

- Luo, Q., Huang, L., Xue, X., Chen, Z., Zhou, F., Wei, L., Hua, J. (2021). Occupational health risk assessment based on dust exposure during earthwork construction. Journal of Building Engineering, 44, 103186. https://doi.org/10.1016/j.jobe.2021.103186

- Install Python support in Visual Studio/Article (2024). Available at: https://learn.microsoft.com/en-us/visualstudio/python/installing-python-support-in-visual-studio?view=vs-2022

- Pandas 3.0. Installation. Available at: https://pandas.pydata.org/pandas-docs/dev/getting_started/install.html

- Derzhavni medyko-sanitarni normatyvy dopustymoho vmistu khimichnykh rechovyn u povitri robochoi zony (2024). Zatverdzheno Nakazom MOZ Ukrainy vid No. 1192. 24.07.2024. Available at: https://zakon.rada.gov.ua/laws/show/z1107-24#n19

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Kateryna Vasiutynska, Angelica Karamushko, Oleksandr Butenko, Sergii Surkov, Serhii Melnyk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.