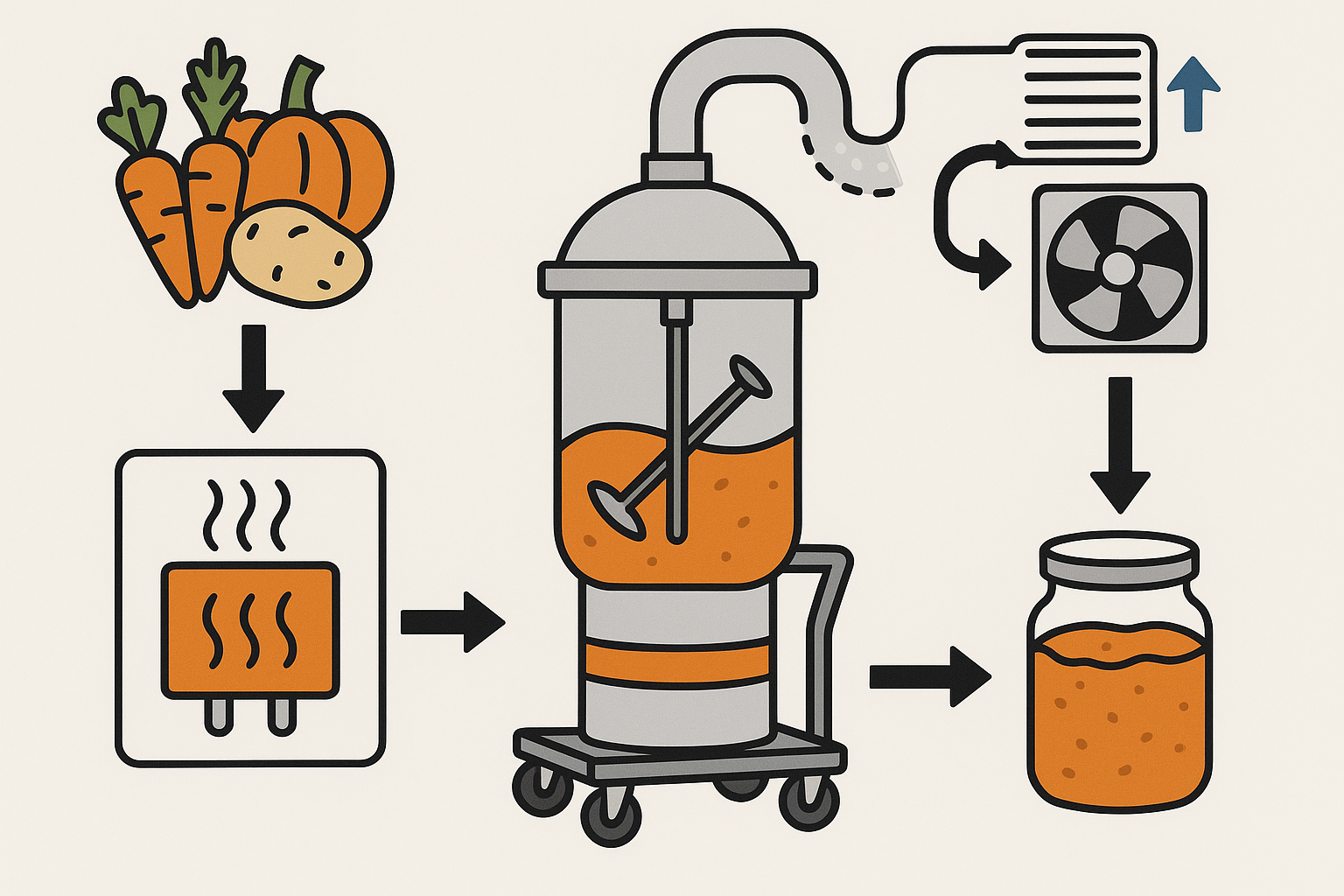

Improvement of a mobile vacuum evaporator for the production of multicomponent vegetable semi-finished products with adjustable thickening for new product formulations

DOI:

https://doi.org/10.15587/2706-5448.2025.344768Keywords:

vacuum evaporator, film-like electric heater, polycomponent semi-finished products, heat recovery, polycomponent vegetable massAbstract

The object of research is the process of manufacturing multicomponent vegetable semi-finished products with adjustable thickening of the mass from Jerusalem artichoke, carrot and pumpkin on an improved mobile vacuum evaporator. Traditional evaporators are characterized by high energy and metal consumption, the presence of a steam jacket with complex temperature range regulation, which leads to an increase in the cycle duration and losses of natural ingredients. The lack of mobility of traditional equipment does not allow it to be used in mobile lines of agricultural complexes and craft production, which is relevant for decentralized use of the device, for example, in front-line regions. In the course of improving the mobile vacuum evaporator, classical methods were used to analyze heat and mass transfer, determine the content and degree of preservation of useful natural ingredients in the conditions of mobile production of multicomponent semi-finished products with adjustable thickening. The design improvement is based on the use of a film-like electric heater of the radiant type, additional increase in the useful heat exchange surface due to the use of a mixer with a heating circuit and Peltier elements for secondary air recovery. Such actions contributed to increasing the resource efficiency of the technological cycle and stabilizing the temperature effect during the controlled thickening of natural masses.

The duration of controlled thickening of multicomponent masses was reduced by 37%, the specific heat consumption by 15.5%, the loss of vitamin C by 21%, the preservation of inulin (94%), β-carotene (87%) and 88% preservation of polyphenols. It is the introduction of electric heating of the working chamber of the apparatus and the artificial increase in the useful heat exchange surface actually due to the mixer circuit, which is heated by 27%, which contributes to the stabilization of the temperature field. And the use of an air thermal insulation jacket allows for the recovery of secondary warm air, further increasing the resource efficiency of the technological cycle. The improvement of the apparatus contributes to the resource-saving processing of plant raw materials into polycomponent semi-finished products of high readiness with adjustable thickening, in particular within 25–45% of dry matter for further introduction into the formulations of new products. A polycomponent semi-finished product of high readiness with adjustable thickening can be used in functional drinks, baby food, confectionery fillings and meat and vegetable products. A comparison of the improved design with basic evaporators is characterized by resource efficiency, mobility for agricultural sectors in conditions of decentralized processing, for example in front-line regions.

Supporting Agency

- The research was carried out within the framework of the state budget theme of the young scientists' project No. 1-24-25 BO “Development of hardware and technological solutions for the production of multi-purpose polycomponent organic semi-finished products and food products in conditions of military operations and post-war reconstruction of the country”, supported by the Ministry of Education and Science of Ukraine. The results were obtained on the basis of the scientific and educational center “Innovative resource-saving technologies for processing organic products” of the State Biotechnological University (Kharkiv, Ukraine).

References

- Zahorulko, A., Cherevko, O., Zagorulko, A., Yancheva, M., Budnyk, N., Nakonechna, Y. et al. (2021). Design of an apparatus for low-temperature processing of meat delicacies. Eastern-European Journal of Enterprise Technologies, 5 (11 (113)), 6–12. https://doi.org/10.15587/1729-4061.2021.240675

- Cherevko, O., Mikhaylov, V., Zahorulko, A., Zagorulko, A., Gordienko, I. (2021). Development of a thermal-radiation single-drum roll dryer for concentrated food stuff. Eastern-European Journal of Enterprise Technologies, 1 (11 (109)), 25–32. https://doi.org/10.15587/1729-4061.2021.224990

- Kasabova, K., Zagorulko, A., Zahorulko, A., Shmatchenko, N., Simakova, O., Goriainova, I. et al. (2021). Improving pastille manufacturing technology using the developed multicomponent fruit and berry paste. Eastern-European Journal of Enterprise Technologies, 3 (11 (111)), 49–56. https://doi.org/10.15587/1729-4061.2021.231730

- Pylypenko, O. (2017). Development of Ukrainian food industry. Scientific Works of NUFT, 23 (3), 15–25. Available at: http://nbuv.gov.ua/UJRN/Npnukht_2017_23_3_4

- Zahorulko, A., Zagorulko, A., Yancheva, M., Ponomarenko, N., Tesliuk, H., Silchenko, E. et al. (2020). Increasing the efficiency of heat and mass exchange in an improved rotary film evaporator for concentration of fruit-and-berry puree. Eastern-European Journal of Enterprise Technologies, 6 (8 (108)), 32–38. https://doi.org/10.15587/1729-4061.2020.218695

- Kiptelaya, L., Zagorulko, A., Zagorulko, A. (2015). Improvement of equipment for manufacture of vegetable convenience foods. Eastern-European Journal of Enterprise Technologies, 2 (10 (74)), 4–8. https://doi.org/10.15587/1729-4061.2015.39455

- O’Shea, N., Ktenioudaki, A., Smyth, T. P., McLoughlin, P., Doran, L., Auty, M. A. E. et al. (2015). Physicochemical assessment of two fruit by-products as functional ingredients: Apple and orange pomace. Journal of Food Engineering, 153, 89–95. https://doi.org/10.1016/j.jfoodeng.2014.12.014

- Huang, L., Bai, L., Zhang, X., Gong, S. (2019). Re-understanding the antecedents of functional foods purchase: Mediating effect of purchase attitude and moderating effect of food neophobia. Food Quality and Preference, 73, 266–275. https://doi.org/10.1016/j.foodqual.2018.11.001

- Marco, S.-C., Adrien, S., Isabelle, M., Manuel, V.-O., Dominique, P. (2019). Flash Vacuum-Expansion Process: Effect on the Sensory, Color and Texture Attributes of Avocado (Persea americana) Puree. Plant Foods for Human Nutrition, 74 (3), 370–375. https://doi.org/10.1007/s11130-019-00749-3

- Zahorulko, A., Zagorulko, A., Kasabova, K., Liashenko, B., Postadzhiev, A., Sashnova, M. (2022). Improving a tempering machine for confectionery masses. Eastern-European Journal of Enterprise Technologies, 2 (11 (116)), 6–11. https://doi.org/10.15587/1729-4061.2022.254873

- Zahorulko, A., Zagorulko, A., Kasabova, K., Shmatchenko, N. (2020). Improvement of zefir production by addition of the developed blended fruit and vegetable pasteinto its recipe. Eastern-European Journal of Enterprise Technologies, 2 (11 (104)), 39–45. https://doi.org/10.15587/1729-4061.2020.185684

- Zagorulko, A., Zahorulko, A., Kasabova, K., Chuiko, L., Yakovets, L., Pugach, A. et al. (2022). Improving the production technology of functional paste-like fruit-and-berry semi-finished products. Eastern-European Journal of Enterprise Technologies, 4 (11 (118)), 43–52. https://doi.org/10.15587/1729-4061.2022.262924

- Zahorulko, A., Zagorulko, A., Mykhailov, V., Ibaiev, E. (2021). Improved rotary film evaporator for concentrating organic fruit and berry puree. Eastern-European Journal of Enterprise Technologies, 4 (11 (112)), 92–98. https://doi.org/10.15587/1729-4061.2021.237948

- Habanova, M., Saraiva, J. A., Holovicova, M., Moreira, S. A., Fidalgo, L. G., Haban, M. et al. (2019). Effect of berries/apple mixed juice consumption on the positive modulation of human lipid profile. Journal of Functional Foods, 60, 103417. https://doi.org/10.1016/j.jff.2019.103417

- Cherevko, A., Kiptelaya, L., Mikhaylov, V., Zagorulko, A., Zagorulko, A. (2015). Development of energy-efficient ir dryer for plant raw materials. Eastern-European Journal of Enterprise Technologies, 4 (8 (76)), 36–41. https://doi.org/10.15587/1729-4061.2015.47777

- Savchenko, T., Lutska, N., Vlasenko, L., Sashnova, M., Zahorulko, A., Minenko, S. et al. (2025). Risk analysis and cybersecurity enhancement of Digital Twins in dairy production. Technology Audit and Production Reserves, 2 (2 (82)), 37–49. https://doi.org/10.15587/2706-5448.2025.325422

- Zahorulko, A., Voronenko, I., Minenko, S., Pugach, A., Nazarenko, O., Lebedenko, O. et al. (2025). Improving the mobile structure of a vertical modular solar dryer for the agricultural sector From field to fork. Eastern-European Journal of Enterprise Technologies, 1 (11 (133), 6–16. https://doi.org/10.15587/1729-4061.2025.323607

- Zahorulko, A., Voronenko, I., Nikolaienko, M., Minenko, S., Ponomarenko, N., Zakharchenko, R. et al. (2025). Design of a combined apparatus for low-temperature processing of confectionery products based on plant-based multicomponent semi-finished products. Eastern-European Journal of Enterprise Technologies, 4 (11 (136)), 15–24. https://doi.org/10.15587/1729-4061.2025.335468

- Borchani, M., Masmoudi, M., Ben Amira, A., Abbès, F., Yaich, H., Besbes, S. et al. (2019). Effect of enzymatic treatment and concentration method on chemical, rheological, microstructure and thermal properties of prickly pear syrup. LWT, 113, 108314. https://doi.org/10.1016/j.lwt.2019.108314

- Bezusov, A., Totsenko, O. (2017). Analysis of modern methods in tomato processing industry. Food Science and Technology, 11 (2). https://doi.org/10.15673/fst.v11i2.513

- Zahorulko, A., Voronenko, I., Nikolaienko, M., Shevchenko, A., Tytarenko, N., Zhelievа, T. (2025). Justification of the practical implementation of innovative technologies for obtaining polycomponent vegetable semi-finished products for new generation food products. EUREKA: Life Sciences, 2, 68–76. https://doi.org/10.21303/2504-5695.2025.003890

- Faure, E., Shcherba, A., Stupka, B., Voronenko, I., Baikenov, A. (2023). A method for reliable permutation transmission in short-packet communication systems. Lecture Notes on Data Engineering and Communications Technologies. Cham: Springer, 178, 177–195. https://doi.org/10.1007/978-3-031-35467-0_12

- Granaturov, V., Kaptur, V., Politova, I. (2015). Determination of tariffs for telecommunication services on the cost simulation modeling. Economic Annals – XXI, 1-2 (1), 52–56. Available at: https://ea21journal.world/wp-content/uploads/2022/04/ea-V147-13.pdf

- Taskila, S., Ahokas, M., Järvinen, J., Toivanen, J., Tanskanen, J. P. (2017). Concentration and Separation of Active Proteins from Potato Industry Waste Based on Low-Temperature Evaporation and Ethanol Precipitation. Scientifica, 2017, 1–6. https://doi.org/10.1155/2017/5120947

- Bozhenko, V., Boyko, A., Voronenko, I. (2023). Corruption as an obstacle of sustainable development. Leadership, Entrepreneurship and Sustainable Development Post COVID-19. NILBEC 2022. Springer Proceedings in Business and Economics. Cham: Springer, 395–407. https://doi.org/10.1007/978-3-031-28131-0_27

- Voronenko, I., Nehrey, M., Laptieva, A., Babenko, V., Rohoza, K. (2022). National cybersecurity: assessment, risks and trends. International Journal of Embedded Systems, 15 (3), 226. https://doi.org/10.1504/ijes.2022.124854

- Nehrey, M., Voronenko, I., Salem, A.-B. M. (2022). Cybersecurity Assessment: World and Ukrainian Experience. 2022 12th International Conference on Advanced Computer Information Technologies (ACIT), 335–340. https://doi.org/10.1109/acit54803.2022.9913081

- Voronenko, I., Klymenko, N., Nahorna, O. (2022). Challenges to Ukraine’s Innovative Development in a Digital Environment. Management and Production Engineering Review, 13 (4), 48–58. https://doi.org/10.24425/mper.2022.142394

- Zahorulko, A., Zagorulko, A. (2025). Pat. No. 158521 UA. State biotechnological university. MPK B01D 1/22. No. u202401910; declareted: 11.04.2024; published: 19.02.2025, Bul. No. 8, 4. Available at: https://sis.nipo.gov.ua/uk/search/detail/1842500/

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Lyudmila Chuiko, Nataliia Tytarenko, Andrii Milenin, Hanna Chmil, Sergei Sabadash, Eldar Ibaiev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.