Підвищення міцності будівельної кераміки, виготовленої на основі легкоплавких глин

DOI:

https://doi.org/10.15587/2706-5448.2022.266605Ключові слова:

керамічні матеріали, глиниста сировина, механічна міцність, кремнеземисті матеріали, будівельна кераміка, добавка трепелуАнотація

Об'єктом дослідження є фізико-хімічні процеси формування структури та властивостей, інтенсифікація спікання керамічних мас на основі місцевої сировини (Креничанскої легкоплавкої глинистої сировини Київської області України) шляхом регулювання хіміко-мінералогічного складу та технологічних режимів. При виборі глинистої сировини для конкретних керамічних технологій необхідно керуватися комплексною оцінкою фізико-хімічних властивостей глинистої породи. Такими можуть слугувати гранулометричний та речовинний склади, включаючи хімічний та мінералогічний склади глинистої та домішкової складових, наявність аморфізованого матеріалу. Важливим є і стан упорядкованості структури глиноутворюючих мінералів, знання яких дозволяє визначитися зі шляхами регулювання основних технологічних властивостей глинистої породи з метою доведення їх до необхідного рівня.

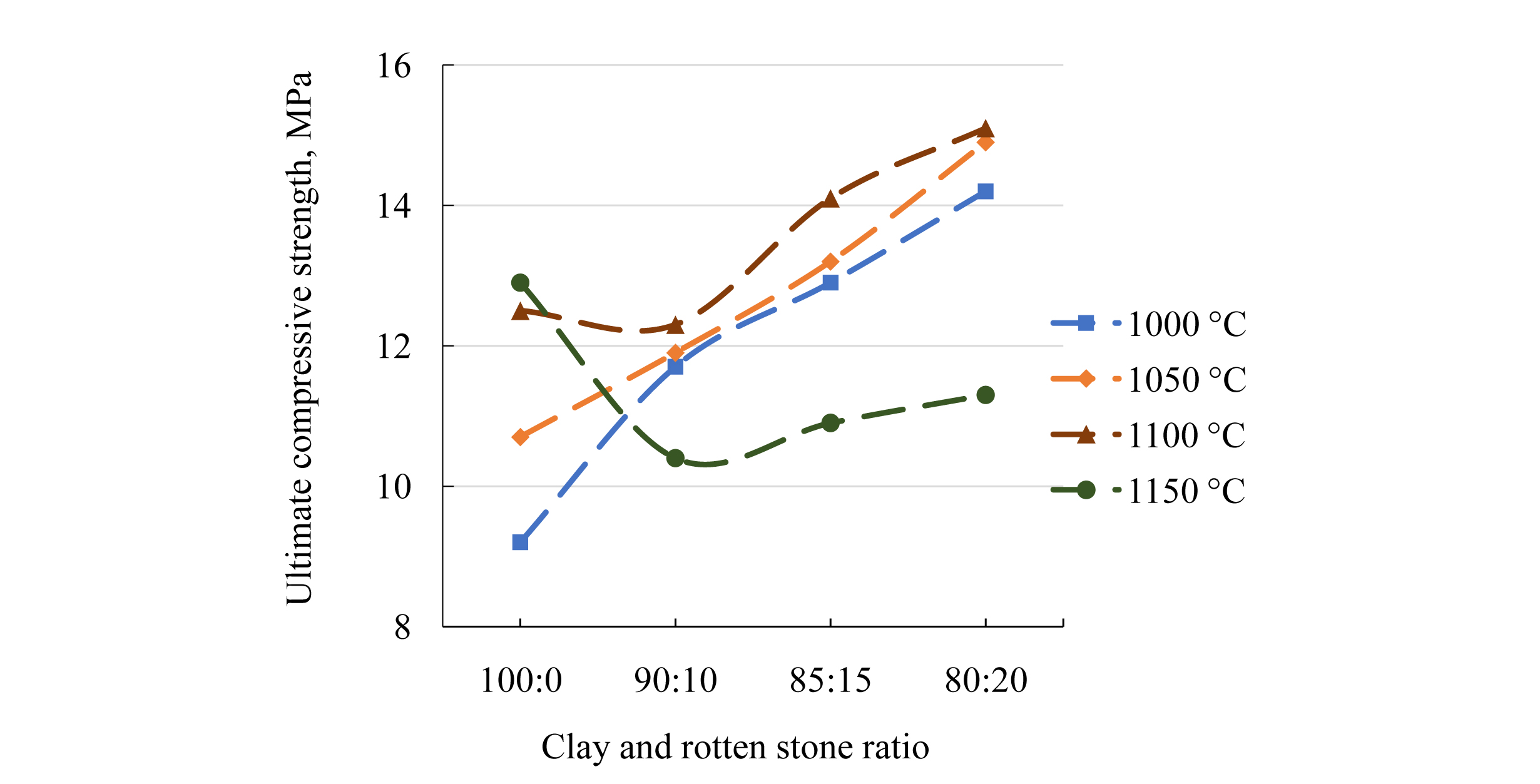

Серед фізико-механічних властивостей механічна міцність є одним з основних критеріїв для визначення придатності сировинних матеріалів для виробництва виробів будівельної кераміки. Проведені дослідження показали, що при збільшенні кількості добавки трепела, що вводився від 10 до 20 % до легкоплавкої глини, механічна міцність керамічних зразків при стискуванні та вигині збільшується. Введення добавки трепелу забезпечує підвищення коефіцієнта чутливості до сушіння легкоплавкої глинистої сировини, що позитивно позначається на тріщиностійкості цеглини-сирцю при сушінні глинистої породи з метою доведення їх до необхідного рівня.

Застосування у складі керамічних мас на основі легкоплавких глин кремнеземистих матеріалів в якості добавки для поліпшення фізико-механічних характеристик готової продукції показало свою ефективність. Це можна пояснити тим, що характер взаємодії кремнеземистих добавок, в якості якої використовували трепел, відрізняється від взаємодії з водою глинистих мінералів, які присутні в керамічній сировині. Так як у трепелі кремнезем існує у вигляді аморфного силікагелю, він сприяє поліпшенню структури глини, робить її монолітною, підвищуючи механічну міцність. Домішки легкоплавких оксидів, які входять до складу трепелу, сприяють утворенню легкоплавкої евтектики, знижуючи вогнетривкість аморфного кремнезему та позитивно впливають на процес спікання, утворюючи склофазу

Спонсор дослідження

- Дослідження проводилося без фінансової підтримки, в рамках Пошукової теми «Керамічні матеріали на основі мінеральної сировини Київського регіону» номер Держреєстрації 0122U000523.

Посилання

- Manoj, D. (2021). Ceramic Technology Diploma&Engineering MCQ. Objective question answers, 107.

- Shestakov, V. L. (2002). Tekhnolohiia keramichnykh stinovykh i lytsiuvalnykh materialiv. Rivne: UDUVHiP, 243.

- Jensen, N. C. (2009). Marketing Silica (quartz, Tripoli, Diatomite, Etc.). Bureau of Mines, Information circular, 7202, 39.

- Şan, O., Gören, R., Özgür, C. (2009). Purification of diatomite powder by acid leaching for use in fabrication of porous ceramics. International Journal of Mineral Processing, 93 (1), 6–10. doi: https://doi.org/10.1016/j.minpro.2009.04.007

- Mymrine, V., Ponte, M. J. J. S., Ponte, H. A., Kaminari, N. M. S., Pawlowsky, U., Solyon, G. J. P. (2013). Oily diatomite and galvanic wastes as raw materials for red ceramics fabrication. Construction and Building Materials, 41, 360–364. doi: https://doi.org/10.1016/j.conbuildmat.2012.11.041

- Wiśniewska, K., Pichór, W., Kłosek-Wawrzyn, E. (2021). Influence of Firing Temperature on Phase Composition and Color Properties of Ceramic Tile Bodies. Materials, 14 (21), 6380. doi: https://doi.org/10.3390/ma14216380

- Mačiulaitis, R., Malaiškienė, J. (2009). Possibilities to control ceramics properties by changing firing cycles. Construction and Building Materials, 23 (1), 226–232. doi: https://doi.org/10.1016/j.conbuildmat.2007.12.012

- Lin, K.-L., Chang, J.-C. (2011). Feasibility of recycling waste diatomite and fly ash cosintered as porous ceramics. Environmental Progress & Sustainable Energy, 32 (1), 25–34. doi: https://doi.org/10.1002/ep.10592

- Hao, L., Gao, W., Yan, S., Niu, M., Liu, G., Hao, H. (2019). Preparation and characterization of porous ceramics with low-grade diatomite and oyster shell. Materials Chemistry and Physics, 235, 121741. doi: https://doi.org/10.1016/j.matchemphys.2019.121741

- Hossain, S. S., Mathur, L., Roy, P. K. (2018). Rice husk/rice husk ash as an alternative source of silica in ceramics: A review. Journal of Asian Ceramic Societies, 6 (4), 299–313. doi: https://doi.org/10.1080/21870764.2018.1539210

- Li, S., Bao, C., Ma, H., Dong, W., Song, S., Wang, Q. et al. (2022). Fabrication and properties of diatomite ceramics with hierarchical pores based on direct stereolithography. Ceramics International, 48 (5), 6266–6276. doi: https://doi.org/10.1016/j.ceramint.2021.11.169

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2022 Іrіna Subbota, Larysa Spasonova, Аnastasia Sholom

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.