Search procedure for optimal design and technological solutions to ensure dimensional and geometric accuracy of castings

DOI:

https://doi.org/10.15587/2706-5448.2023.271860Keywords:

shaped castings, dimensional accuracy, geometric accuracy, gating system, design and technological solutionsAbstract

The object of research in the work is the technology of manufacturing shaped castings in disposable sand molds.

The existing problem is that the imperfection of design and technological solutions at the stage of developing the technology of a single sand mold casting leads to deviations in the dimensions and geometry of the castings after their manufacture from the requirements of technological documentation. This can lead to an irreparable shortage of casting.

To develop measures to eliminate or minimize the event, which consists in the formation of a shortage of castings in terms of dimensional and geometric accuracy, a procedure for searching for optimal design and technological solutions is proposed.

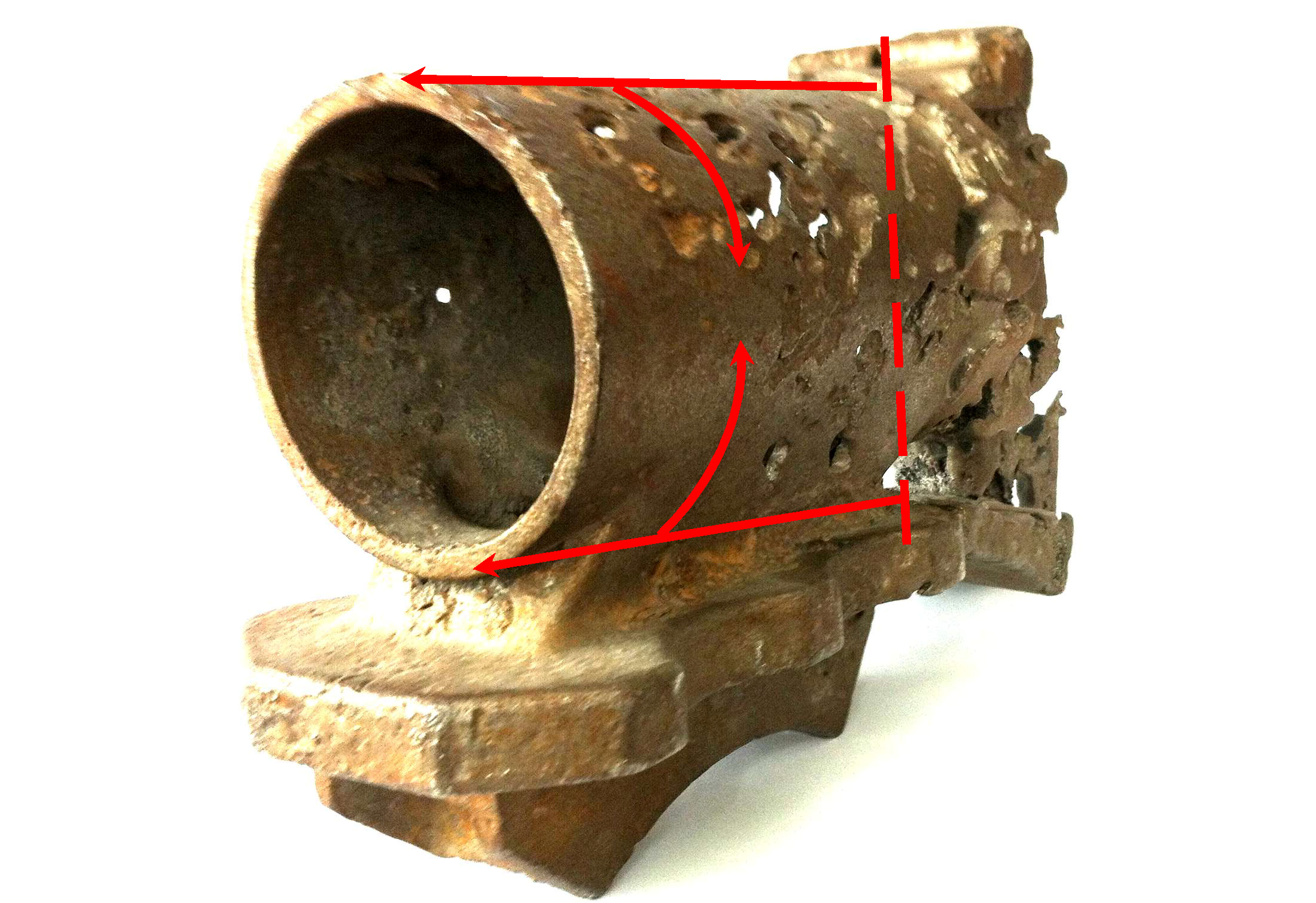

A hypothesis has been put forward that a significant factor that leads to deviations in the dimensional and geometric accuracy of castings from the requirements of technological documentation is the imperfection of the gating system design. It is demonstrated on specific castings how this factor can influence the formation of uneven wall thickness.

The proposed procedure, which includes 10 consecutive steps, allows to build a plan for a complete factorial experiment and obtain a regression equation for it, linking the parameters of the gating system with indicators of dimensional and geometric accuracy. The presence of such equations provides the possibility of further experimental optimization and determination of design and technological solutions for the development or improvement of casting systems that minimize the deviations of the dimensional and geometric accuracy of castings from the requirements of technological documentation. This also minimizes the likelihood of an event consisting in the formation of an irreparable shortage of castings.

The presented study will be useful for machine-building enterprises that have foundries in their structure, where shaped castings are made in disposable sand molds.

References

- ElMaraghy, W., ElMaraghy, H., Tomiyama, T., Monostori, L. (2012). Complexity in engineering design and manufacturing. CIRP Annals, 61 (2), 793–814. doi: https://doi.org/10.1016/j.cirp.2012.05.001

- ElMaraghy, W. H., Urbanic, R. J. (2003). Modelling of Manufacturing Systems Complexity. CIRP Annals, 52 (1), 363–366. doi: https://doi.org/10.1016/s0007-8506(07)60602-7

- Joshi, D., Ravi, B. (2010). Quantifying the Shape Complexity of Cast Parts. Computer-Aided Design and Applications, 7 (5), 685–700. doi: https://doi.org/10.3722/cadaps.2010.685-700

- Budiono, H. D. S., Nurdian, D., Indianto, M. A., Nugroho, H. S. (2022). Development of a process complexity index of low pressure die casting for early product design evaluation. Eastern-European Journal of Enterprise Technologies, 6 (1 (120)), 101–108. doi: https://doi.org/10.15587/1729-4061.2022.264984

- Demin, D. (2018). Investigation of structural cast iron hardness for castings of automobile industry on the basis of construction and analysis of regression equation in the factor space «carbon (C) – carbon equivalent (Ceq)». Technology Audit and Production Reserves, 3 (1 (41)), 29–36. doi: https://doi.org/10.15587/2312-8372.2018.109097

- Demin, D. A. (1998). Change in cast iron’s chemical composition in inoculation with a Si-V-Mn master alloy. Litejnoe Proizvodstvo, 6, 35.

- Chibichik, O., Sil’chenko, K., Zemliachenko, D., Korchaka, I., Makarenko, D. (2017). Investigation of the response surface describing the mathematical model of the effects of the Al/Mg rate and temperature on the Al-Mg alloy castability. ScienceRise, 5 (2), 42–45. doi: https://doi.org/10.15587/2313-8416.2017.101923

- Ponomarenko, O. Y., Trenev, N. S. (2013). Computer modeling of crystallization processes as a reserve of improving the quality of pistons of ICE. Technology Audit and Production Reserves, 6 (2 (14)), 36–40. doi: https://doi.org/10.15587/2312-8372.2013.19529

- Akimov, O. V. (2003). Analiz pogreshnostei formoobrazovaniia otlivok koles turbin turbokompressorov dlia nadduva DVS na etape izgotovleniia ikh voskovykh modelei. Eastern-European Journal of Enterprise Technologies, 3 (3), 16–24.

- Orendarchuk, Y., Marynenko, D., Borysenko, S., Loek, I., Anan’in, V. (2017). Monitoring of castings quality for use in cad systems of foundry production technologies. ScienceRise, 4 (2 (33)), 48–52. doi: https://doi.org/10.15587/2313-8416.2017.99442

- Penzev, P., Pulyaev, A., Gulaga, M., Vlasiuk, V., Makarenko, D. (2017). Parametric classification of pistons of internal combustion engines parts according to the «hole axis shift relative to the piston axis» criterion. ScienceRise, 5 (2 (34)), 38–41. doi: https://doi.org/10.15587/2313-8416.2017.101975

- Demin, D. (2019). Development of «whole» evaluation algorithm of the control quality of «cupola – mixer» melting duplex process. Technology Audit and Production Reserves, 3 (1 (47)), 4–24. doi: https://doi.org/10.15587/2312-8372.2019.174449

- Kuryn, M. (2011). Determination of optimum performance liquid glass of magnetization mixtures with liquid glass. Technology Audit and Production Reserves, 2 (2 (2)), 14–20. doi: https://doi.org/10.15587/2312-8372.2011.4860

- Demin, D. (2017). Strength analysis of lamellar graphite cast iron in the «carbon (C) – carbon equivalent (Ceq)» factor space in the range of C=(3,425–3,563) % and Ceq=(4,214–4,372) %. Technology Audit and Production Reserves, 1 (1 (33)), 24–32. doi: https://doi.org/10.15587/2312-8372.2017.93178

- Demin, D. (2017). Synthesis of optimal control of technological processes based on a multialternative parametric description of the final state. Eastern-European Journal of Enterprise Technologies, 3 (4 (87)), 51–63. doi: https://doi.org/10.15587/1729-4061.2017.105294

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Liliia Frolova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.