Consideration of the issue of regulating low-frequency vibrations of the drill string when drilling with a downhole motor

DOI:

https://doi.org/10.15587/2706-5448.2024.302255Keywords:

drill string, downhole motor, bit, low-frequency oscillations, oscillatory processes, hole deepeningAbstract

The object of research is the dynamic processes that occur in the drill string during the deepening of the hole in deep wells. The work is aimed at solving the problem for an idealized system in the form of rod systems while preserving its main oscillatory properties.

The nature of oscillatory processes that occur in the drill string during drilling with downhole motors is considered, in some cases it turns out to be very complicated. In the general case, the dynamic process changes according to an aperiodic law, which is superimposed by processes of an oscillating nature with an increasing (damping) nature of the amplitudes of different frequencies.

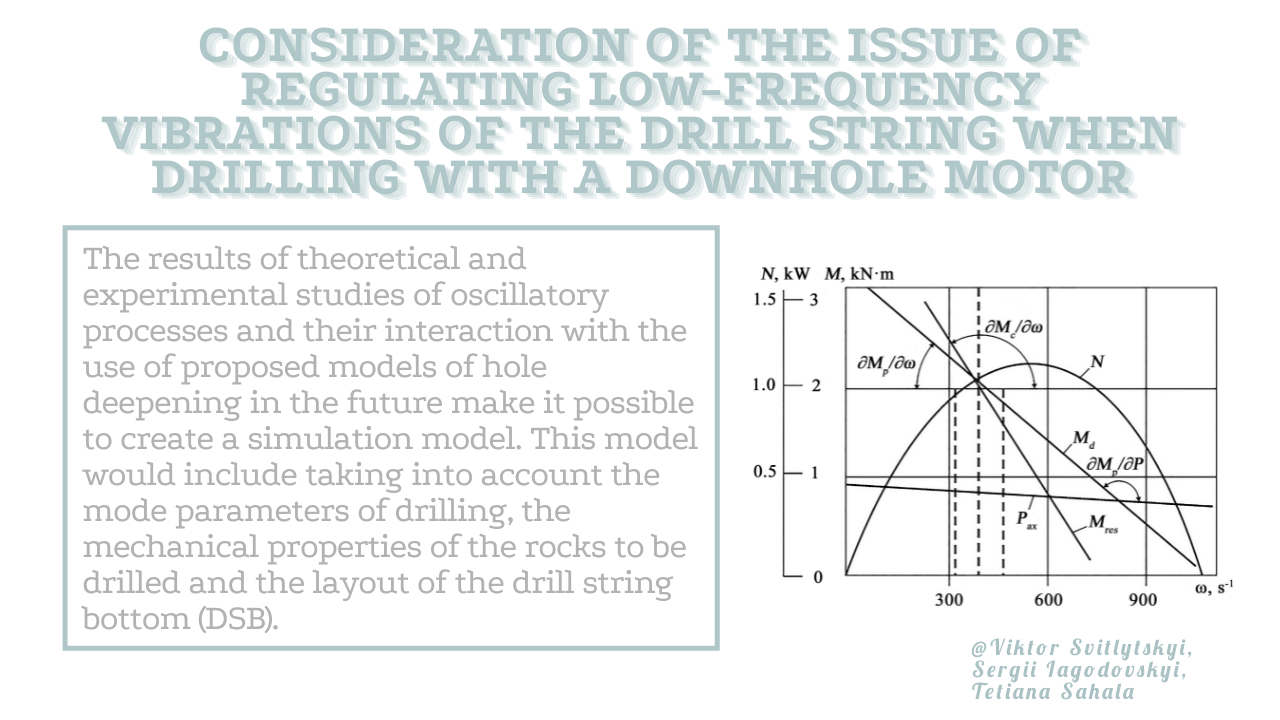

The influence of the torque characteristics of the downhole motor and bit on the development of oscillatory processes in the drill string during well drilling has been theoretically determined.

The results of theoretical and experimental studies of oscillatory processes and their interaction with the use of proposed models of hole deepening in the future make it possible to create a simulation model. This model would include taking into account the mode parameters of drilling, the mechanical properties of the rocks to be drilled and the layout of the drill string bottom (DSB).

The obtained research results can be applied in practice in the process of designing the structure of the drill string bottom (DSB) with the use of downhole motors, in particular, screw motors, the use of which leads to energy stress, the complication of work processes and structural schemes. As a result, the nature of vibrations changes and the vibration loads on parts of the downhole motor, bits and elements of the drill string are reduced.

In the future, it is necessary to take into account the hydrodynamics and the type, as well as the design and parameters of the applied downhole elements for the development of their dynamic models.

References

- Zhang, X. D., Zhu, X. F., He, S., et al. (2015). Stability analysis of stick-slip vibration and discussion of vibration reduction method of drill string system. Drill Prod Technol, 38, 89–90.

- Xiaohua, Z., Liping, T., Pingping, M. et al. (2012). Stick-slip vibration mechanism analysis of PDC bit. Oil Field Equipment, 41, 13–16.

- Gusman, M. T., Liubimov, B. G., Nikitin, G. M. et al. (1976). Raschet, konstruiravanie i ekspluatatciia turboburov. Nedra, 368.

- Vaziri, V., Kapitaniak, M., Wiercigroch, M. (2018). Suppression of drill-string stick–slip vibration by sliding mode control: Numerical and experimental studies. European Journal of Applied Mathematics, 29 (5), 805–825. doi: https://doi.org/10.1017/s0956792518000232

- Richard, T., Germay, C., Detournay, E. (2007). A simplified model to explore the root cause of stick–slip vibrations in drilling systems with drag bits. Journal of Sound and Vibration, 305 (3), 432–456. doi: https://doi.org/10.1016/j.jsv.2007.04.015

- Ogorodnikov, P. I. (1991). Upravlenie uglubleniem skvazhini na baze izucheniia dinamicheskikh protcesov v burilnoi kolone. Doctoral dissertation.

- Besaisow, A. A., Payne, M. L. (1988). A Study of Excitation Mechanisms and Resonances Inducing Bottomhole-Assembly Vibrations. SPE Drilling Engineering, 3 (1), 93–101. doi: https://doi.org/10.2118/15560-pa

- Aarrestad, T. V., Kyllingstad, Å. (1988). An Experimental and Theoretical Study of a Coupling Mechanism Between Longitudinal and Torsional Drillstring Vibrations at the Bit. SPE Drilling Engineering, 3 (1), 12–18. doi: https://doi.org/10.2118/15563-pa

- Fomenko, F. N. (1974). Burenie skvazhin elektroburom. Moscow: Nedra, 267.

- Bashmal, S. M. (2005). Finite element analysis of stick-slip vibrations in drillstrings. King Fahd University of Petroleum and Minerals.

- Haiwei, M., YingWand Chunjie, H. (2011). Analysis of stick-slip vibration of drill string. China Petr Mach, 39, 67–69.

- Grigorian, N. A., Bagirov, R. E. (1982). Analiz protcessov turbinnogo bureniia. Nedra, 207.

- Finnie, I., Bailey, J. J. (1960). An Experimental Study of Drill-String Vibration. Journal of Engineering for Industry, 82 (2), 129–135. doi: https://doi.org/10.1115/1.3663020

- Gureev, I. L. (1975). Issledovanie dinamiki sharoshechnogo dolota po informatcii na uste skvazhiny. Doctoral dissertation.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Viktor Svitlytskyi, Sergii Iagodovskyi, Tetiana Sahala

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.