Optimization of coagulation wastewater treatment of leather industry

DOI:

https://doi.org/10.15587/2706-5448.2024.303183Keywords:

wastewater from leather factories, coagulation, degree of treatment, optimal parameters of the coagulation processAbstract

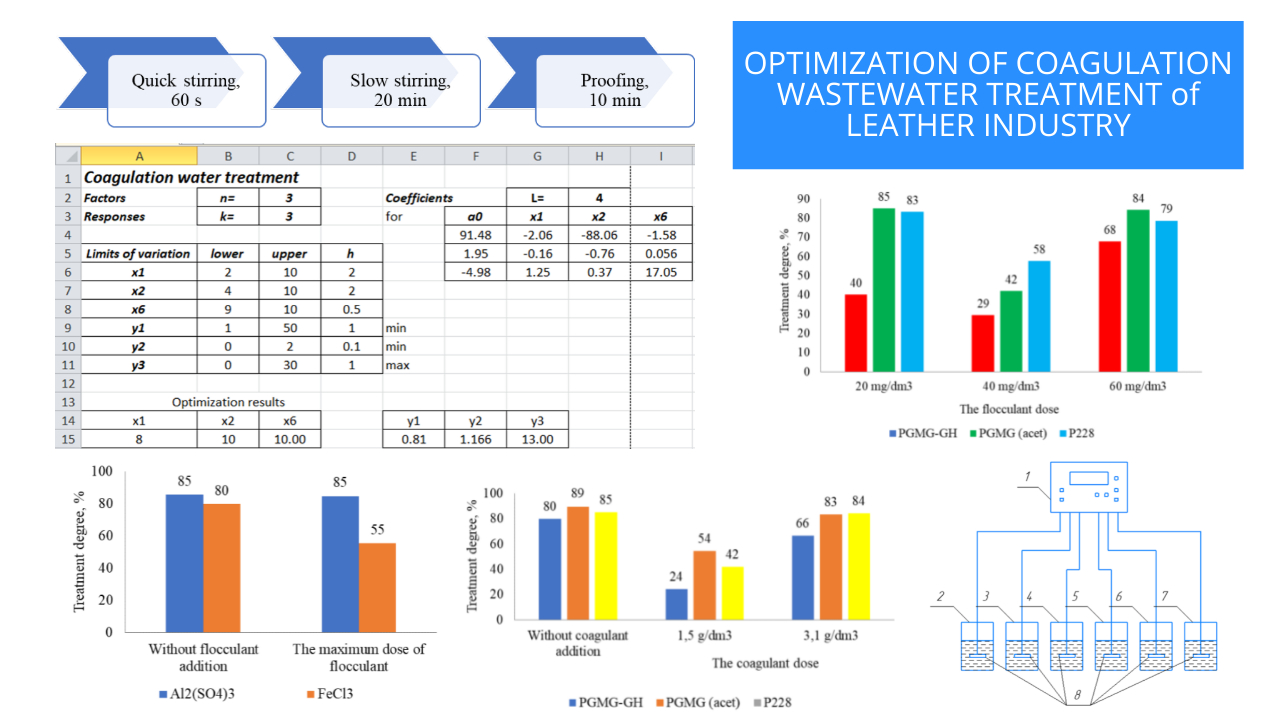

The object of the study was the process of coagulation treatment of wastewater of leather industry enterprises. The treatment of samples of real wastewater from a leather production was investigated. Such wastewater is characterized by high concentrations of pollutants of varying degrees of dispersion, which is due to the use of a large number of various chemicals in the leather production process. During technological operations related to the skinning and processing of skins, these substances enter the wastewater, which is discharged into the sewer. A peculiarity of leather production wastewater is large fluctuations in composition and volume, high concentrations of pollutants, and an increased content of suspended solids. Such waters have certain toxicity. The existing methods of wastewater treatment of leather industry enterprises do not provide the necessary treatment efficiency, do not allow to create a closed circulation of water at enterprises, to use or regenerate valuable components of wastewater, and to ensure their economically feasible disposal. Therefore, the research is aimed at improving the process of coagulation wastewater treatment of leather factories using mathematical modeling and optimization methods. This will make it possible to modernize existing wastewater treatment schemes. The experiments were carried out on the Niva Jar-test laboratory unit, which allows simultaneous examination of 6 samples. Samples of wastewater from leather production after the fattening-filling and dyeing stages were studied. The effectiveness of the coagulation process was determined by the degree of wastewater treatment. The factors were analyzed and the intervals of variation of factors that have a significant impact on the process of coagulation treatment of wastewater from leather factories were established. An experiment plan was drawn up and implemented in order to study the effect of coagulants based on aluminum and ferrum, as well as flocculants on the quality of wastewater treatment. The choice of quality indicators of the coagulation process is substantiated. A statistical analysis of the results of experimental studies was performed, a correlational analysis of the interdependence of parameters and indicators of the quality of the coagulation process was performed. Aluminum-based coagulant has been found to be more effective than iron-based coagulant. The results of mathematical modeling were used to determine the optimal parameters of the coagulation process: pH 10, coagulant dose – 2.5 g/dm3, flocculant dose – 100 mg/dm3.

References

- Vinayagam, V., Sikarwar, D., Das, S., Pugazhendhi, A. (2024). Envisioning the innovative approaches to achieve circular economy in the water and wastewater sector. Environmental Research, 241, 117663. doi: https://doi.org/10.1016/j.envres.2023.117663

- Bellver-Domingo, Á., Hernández-Sancho, F. (2022). Circular economy and payment for ecosystem services: A framework proposal based on water reuse. Journal of Environmental Management, 305, 114416. doi: https://doi.org/10.1016/j.jenvman.2021.114416

- Chojnacka, K., Skrzypczak, D., Mikula, K., Witek-Krowiak, A., Izydorczyk, G., Kuligowski, K. (2021). Progress in sustainable technologies of leather wastes valorization as solutions for the circular economy. Journal of Cleaner Production, 313, 127902. doi: https://doi.org/10.1016/j.jclepro.2021.127902

- Hu, J., Xiao, Z., Zhou, R., Deng, W., Wang, M., Ma, S. (2011). Ecological utilization of leather tannery waste with circular economy model. Journal of Cleaner Production, 19 (2-3), 221–228. doi: https://doi.org/10.1016/j.jclepro.2010.09.018

- Hu, Q., Bin, L., Li, P., Fu, F., Guan, G., Hao, X., Tang, B. (2021). Highly efficient removal of dyes from wastewater over a wide range of pH value by a self-adaption adsorbent. Journal of Molecular Liquids, 331, 115719. doi: https://doi.org/10.1016/j.molliq.2021.115719

- Sablii, L. A. (2013). Fizyko-khimichne ta biolohichne ochyshchennia vysokokontsentrovanykh stichnykh vod. Rivne: NUVHP, 291.

- Xia, Y., Jin, Y., Qi, J., Chen, H., Chen, G., Tang, S. (2021). Preparation of biomass carbon material based on Fomes fomentarius via alkali activation and its application for the removal of brilliant green in wastewater. Environmental Technology & Innovation, 23, 101659. doi: https://doi.org/10.1016/j.eti.2021.101659

- Kumar, R., Basu, A., Bishayee, B., Chatterjee, R. P., Behera, M., Ang, W. L. et al. (2023). Management of tannery waste effluents towards the reclamation of clean water using an integrated membrane system: A state-of-the-art review. Environmental Research, 229, 115881. doi: https://doi.org/10.1016/j.envres.2023.115881

- Mim, S., Hashem, M. A., Payel, S. (2023). Coagulation-adsorption-oxidation for removing dyes from tannery wastewater. Environmental Monitoring and Assessment, 195 (6). doi: https://doi.org/10.1007/s10661-023-11309-3

- Mim, S., Hashem, Md. A., Maoya, M. (2024). Adsorption-oxidation process for dyestuff removal from tannery wastewater. Environmental Nanotechnology, Monitoring & Management, 21. doi: https://doi.org/10.1016/j.enmm.2023.100911

- Haddad, K., Hantous, A., Chagtmi, R., Khedhira, H., Chaden, C., Ben Hassen Trabelsi, A. (2022). Industrial dye removal from tannery wastewater by using biochar produced from tannery fleshing waste: a road to circular economy. Comptes Rendus. Chimie, 25 (S2), 43–60. doi: https://doi.org/10.5802/crchim.148

- Chowdhury, M., Mostafa, M. G., Biswas, T. K., Saha, A. K. (2013). Treatment of leather industrial effluents by filtration and coagulation processes. Water Resources and Industry, 3, 11–22. doi: https://doi.org/10.1016/j.wri.2013.05.002

- Katheresan, V., Kansedo, J., Lau, S. Y. (2018). Efficiency of various recent wastewater dye removal methods: A review. Journal of Environmental Chemical Engineering, 6 (4), 4676–4697. doi: https://doi.org/10.1016/j.jece.2018.06.060

- Sachidhanandham, A., Periyasamy, A. P. (2020). Environmentally Friendly Wastewater Treatment Methods for the Textile Industry. Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications. Cham: Springer, 1–40. doi: https://doi.org/10.1007/978-3-030-11155-7_54-1

- Volokyta, A. M., Selivanov, V. L. (2022). Osnovy teorii planuvannia eksperymentu: Rozdil dystsypliny «Metodyka ta orhanizatsiia naukovykh doslidzhen». Kyiv: KPI im. Ihoria Sikorskoho, 41.

- Nabyvanets, B. Y., Sukhan, V. V., Kalabina, L. V. (1996). Analitychna khimiia pryrodnoho seredovyshcha. Kyiv: Lybid, 304.

- Matematychne ta kompiuterne modeliuvannia khimichnykh i tekhnolohichnykh protsesiv ta system (2020). Available at: https://kxtp.kpi.ua/index.php/uk/science/scientific-school

- Sanhinova, O. V., Bondarenko, S. H. (2021). AC No. 105383 UA. Kompiuterna prohrama «OPTIMIZ-M». declareted: 09.06.2021, Bul. No. 65.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Olga Sanginova, Nataliia Tolstopalova, Tetiana Obushenko, Аnatolii Danylkovych

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.