Creation of an identifier database for the ammonia synthesis computer control system

DOI:

https://doi.org/10.15587/2706-5448.2024.307213Keywords:

algorithmic database, identifier, computer-integrated control system, ammonia productionAbstract

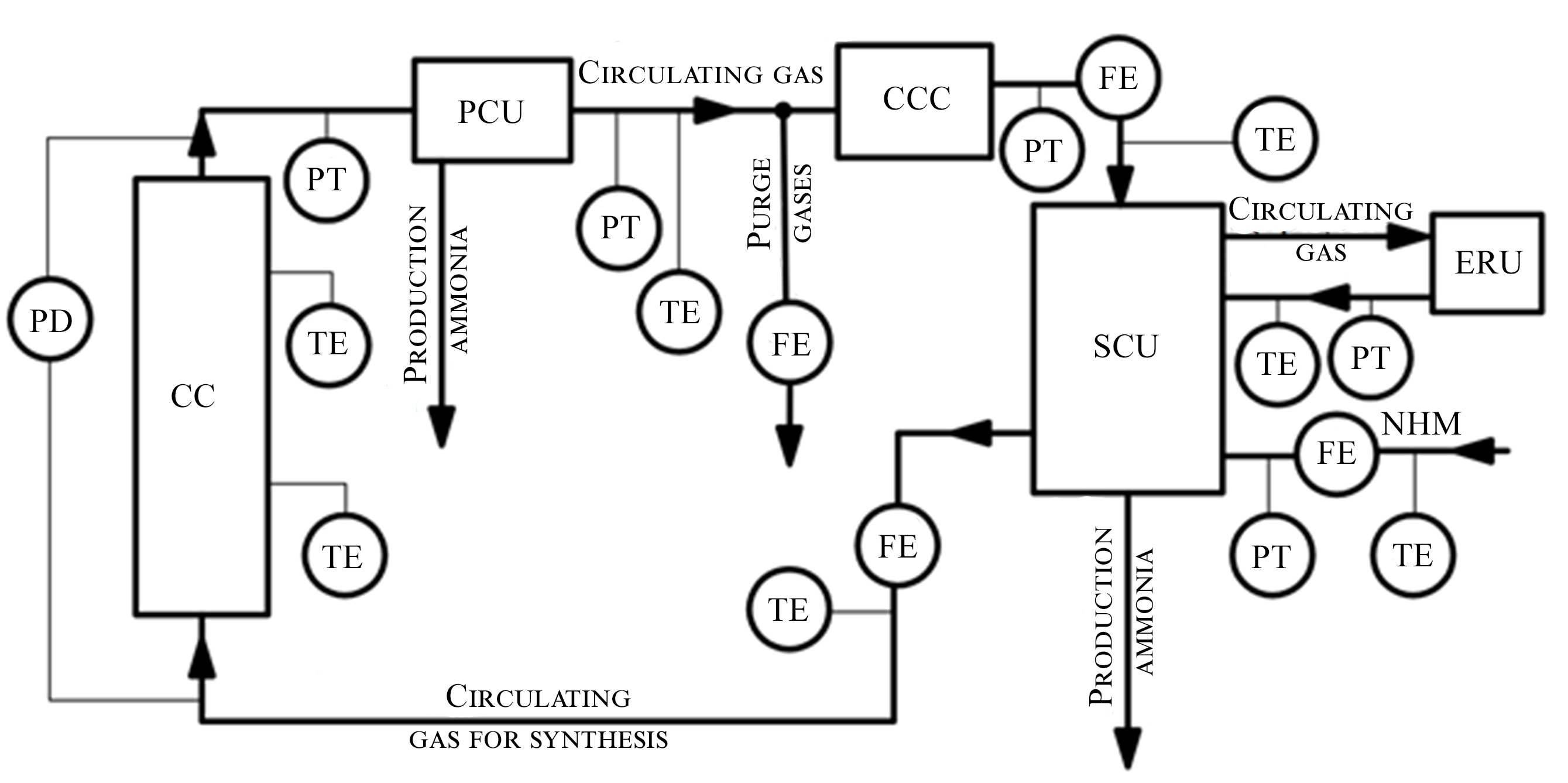

The object of research is the control system of the synthesis department of the large-tonnage ammonia production unit of the AM-1360 series. An analysis of the functioning conditions of the synthesis department was carried out. The significant influence of the content of inerts in the synthesis cycle on the energy efficiency of ammonia production is shown, the optimal value of which depends both on the accepted level of prices for energy carriers and on the method of using purge gases. The need to create a computer-integrated control technology to optimize the use of purge gases is established. The function of the identifier of such a control technology is defined, namely, continuous refinement based on current information about the state of the main sections of the synthesis department, such as the synthesis column, primary and secondary condensation. The operation of these stations takes place in the conditions of seasonal and daily changes in the heat load, which causes parametric uncertainty of such parameters of the connection of the mathematical model as the concentration of ammonia in the circulating gas at the outlet of the stations listed above. Numerical assessment of these uncertainties according to the results of analytical studies for such technological objects is most often performed using stochastic approximation methods. Let’s note that the significant inertia of the objects of the synthesis department under certain conditions makes it impossible to adapt the parameter to its actual value.

An algorithmic base has been created for the formation of an information array of the identifier of the computer-integrated control technology of the ammonia synthesis department, which ensures the separation of transient modes under conditions of uncertainty and allows to perform the task of identifying processes in the synthesis column, in the primary and secondary condensation units. The proposed algorithm allows to perform convergence in the department both on the general and on the component material balances. The algorithm is implemented in the MatLab application program package and tested by means of simulation based on experimental data of industrial operation of AM-1360 series ammonia synthesis units.

References

- Dybkjoker, I. (2013). 100 Years of Ammonia Synthesis Technology. 58th Annual Safety in Ammonia Plants and Related Facilities Symposium. Frankhfurt. Available at: https://www.aiche.org/sites/default/files/docs/conferences/8096_Ammonia2013_Committee_Flyer_v8_0.pdf

- Babichenko, A., Babichenko, J., Kravchenko, Y., Velma, S., Krasnikov, I., Lysachenko, I. (2018). Identification of heat exchange process in the evaporators of absorption refrigerating units under conditions of uncertainty. Eastern-European Journal of Enterprise Technologies, 1 (2 (91)), 21–29. doi: https://doi.org/10.15587/1729-4061.2018.121711

- Babychenko, A. K. (2013). Optimization of operating load conditions of the synthesis branch of ammonia productions. Technology Audit and Production Reserves, 5 (2 (13)), 4–7. doi: https://doi.org/10.15587/2312-8372.2013.18358

- Chen, H., Guo, F. L. (1986). Optimal stochastic adaptive control with quadratic index. International Journal of Control, 43 (3), 869–881. doi: https://doi.org/10.1080/00207178608933508

- Banga, J. R., Seider, W. D. (1996). Global Optimization of Chemical Processes using Stochastic Algorithms. State of the Art in Global Optimization, 563–583. doi: https://doi.org/10.1007/978-1-4613-3437-8_33

- Chen, H. F., Zhang, J. F. (1990). Stochastic adaptive control for AR-MAX systems with unknown orders, time delay and cefficients. 11-th IFAC World Congress. Preprints, 4, 81–86.

- Loboiko, O. Ia., Tovazhnianskyi, L. L., Slabun, I. O. et al. (2001). Metody rozrakhunkiv u tekhnolohii neorhanichnykh vyrobnytstv Chastyna. 1. Zviazanyi azot. Kharkiv: NTU «KhPI», 512.

- Ladaniuk, A. P., Reshetiuk, V. M., Kyshenko, V. D., Smitiukh, Ya. V. (2014). Innovatsiini tekhnolohii v upravlinni skladnymy biotekhnolohichnymy obiektamy ahropromyslovoho kompleksu. Kyiv: Tsentr uchbovoi literatury, 280.

- Salahuddin, T. (2023). Numerical Techniques in MATLAB: Fundamental to Advanced Concepts. Chapman and Hall/CRC. doi: https://doi.org/10.1201/9781003385288

- Tovazhnianskyi, L. L., Loboiko, O. Ia., Hryn, H. I. et al. (2007). Tekhnolohiia zviazanoho azotu. Kharkiv: NTU «KhPI», 537.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Anatoliy Babichenko, Igor Krasnikov, Juliya Babichenko, Oleksandr Dzevochko, Ihor Lysachenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.