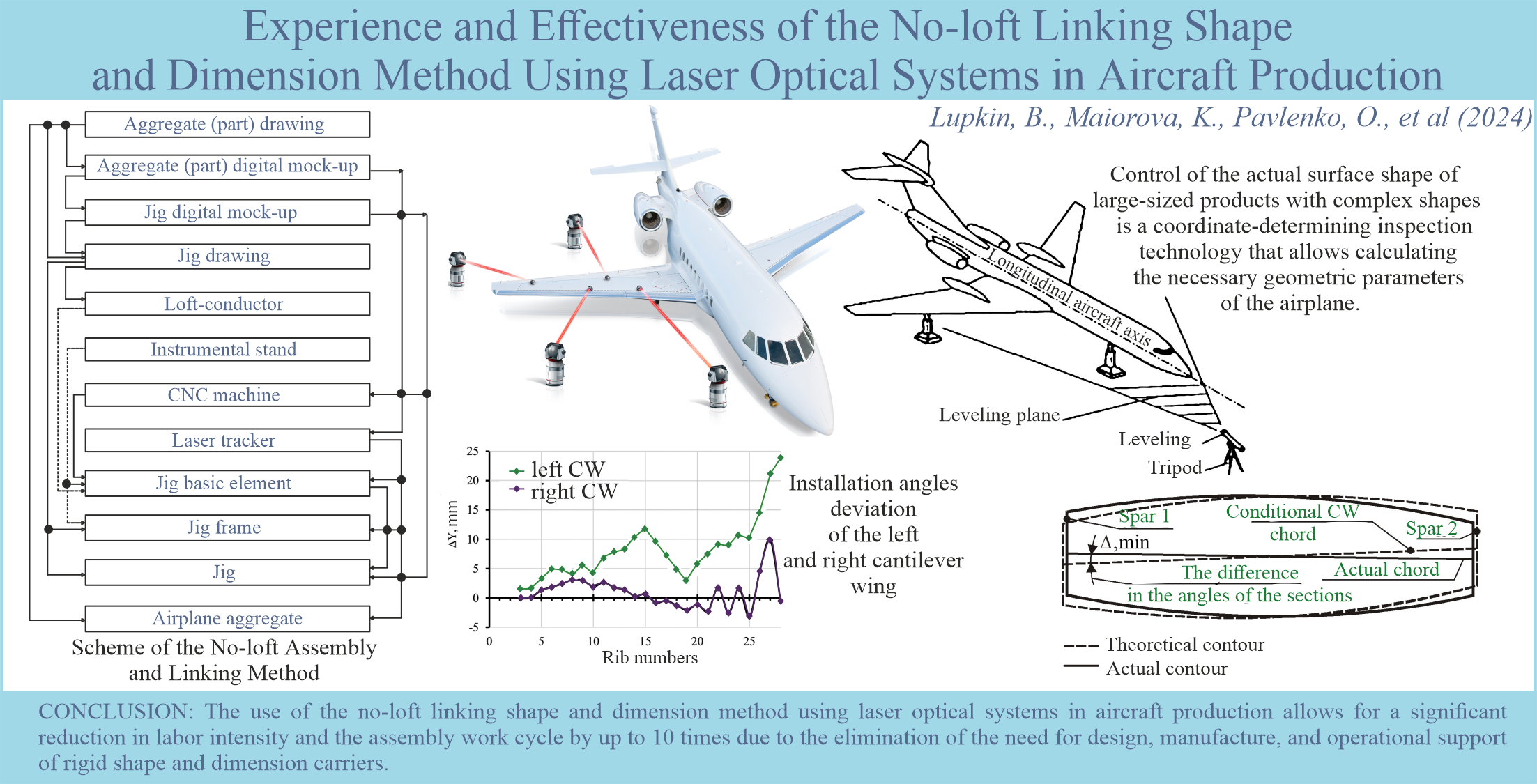

Experience and effectiveness of the no-loft linking shape and dimension method using laser optical systems in aircraft production

DOI:

https://doi.org/10.15587/2706-5448.2024.307330Keywords:

accuracy of aircraft contours, laser means of inspection, aggregate digital mock-up, no-loft assembly method, laser tracker, aircraft levelingAbstract

The object of research is the application of the no-loft linking shapes and dimension method using laser measuring tools to reduce the labor intensity and cycle of mounting work. The study of the accuracy of the geometric parameters of cantilever wing and technological equipment at various stages of production was carried out. The problem is to create a method of using laser optical systems in aircraft production at the stage of mounting of technological equipment to minimize the impact on the accuracy of the dimensions of assembled parts of aggregates. The following results were obtained: the advantages of using the no-loft linking method in the modern production of aviation equipment were analyzed, which makes it possible to reduce the preparation cycle by 2–3 times. A study was conducted on the effective use of the Coordinate Measuring Machine (CMM) of laser tracker in the manufacture of the cantilever wing (CW) of the AN series airplane at all stages of mounting, as well as on the accuracy inspection of geometric parameters in comparison with the theoretical master geometry (MG).

The practical significance of the research is that the proposed method of using laser optical systems during the installation of equipment allows to reduce to a minimum the impact on the accuracy of low rigidity frames. And also, to reduce the equipment deformation due to the mass of the parts of the assembled aggregates and temperature deformations, which allows to ensure a reduction of the mounting error to ±0.1 mm. Also, the application of this technique allows to enter the plane's coordinate system without prior leveling, to mounting and inspection the installation of the wing, fin, stabilizer, engines and landing gear on the fuselage. In general, the application of the no-loft linking shape and dimension method with using laser optical systems in aircraft production allows to reduce the labor intensity and cycle of mounting work up to 10 times.

References

- DSTU 2232-93. Bazuvannia ta bazy mashynobuduvannia. Terminy ta vyznachennia (1994). Vved. 09.09.93. Kyiv: Derzhstandart Ukrainy, 35.

- Aviatsiini pravyla Ukrainy. Chastyna 21 «Sertyfikatsiia povitrianykh suden, poviazanykh z nymy vyrobiv, komponentiv ta obladnannia, a takozh orhanizatsii rozrobnyka ta vyrobnyka» APU-21 (Part-21) (2019). Nakaz Derzhavnoi aviatsiinoi sluzhby Ukrainy No. 529. 26.04.2019. Available at: https://avia.gov.ua/wp-content/uploads/2017/02/Aviatsijni-pravila-Ukrayini-APU-21Part-21_27_06_2019.pdf

- Donets, O. D. (2019). Naukovi osnovy stvorennia suchasnykh reaktyvnykh rehionalnykh pasazhyrskykh litakiv. PhD Dissertation; Natsionalnyi aviatsiinyi universytet.

- Fiedler, F., Ehrenstein, J., Höltgen, C., Blondrath, A., Schäper, L., Göppert, A., Schmitt, R. (2024). Jigs and Fixtures in Production: A Systematic Literature Review. Journal of Manufacturing Systems, 72, 373–405. doi: https://doi.org/10.1016/j.jmsy.2023.10.006

- Mei, Z., Maropoulos, P. G. (2014). Review of the application of flexible, measurement-assisted assembly technology in aircraft manufacturing. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 228 (10), 1185–1197. doi: https://doi.org/10.1177/0954405413517387

- Bukin, Yu. M., Vorobyov, Yu. A. (2003). Technology of airplanes and helicopters production. Assembling, mounting and testing operations in airplane and helicopter production. Synopses of lections in English and Russian. Kharkiv: National aerospace University «Kharkiv aircraft institute», 331.

- Sikulskiy, V., Boborykin, Yu., Vasilchenko, S., Pyankov, A., Demenko, V. (2006). Technology of airplane and helicopter manufacturing. Fundamentals of aircraft manufacturing. The course lecture for foreign students. Kharkiv: National Aerospace University «Kharkiv Aviation Institute», 206.

- Tereshchenko, Yu. M., Volianska, L. H., Zhyvotovska, K. A. et al.; Tereshchenko, Yu. M. (Ed.) (2006). Tekhnolohiia vyrobnytstva litalnykh aparativ. Kn. 2. Tekhnolohiia skladannia litalnykh aparativ. Kyiv: Knyzhkove vyd-vo NAU, 492.

- Stupnytskyi, V. V. (2009) Efektyvnist vprovadzhennia CALS-tekhnolohii na mashynobudivnykh pidpryiemstvakh Ukrainy. Kontrol yakosti, informatsiini i vymiriuvalni systemy. Lviv: Natsionalnyi universytet «Lvivska politekhnika», 80–84.

- Tokarchuk, D. V. (2022). Perspektyvy rozvytku intehratsiinykh protsesiv u lohistychnii systemi Ukrainy. Spetsialnist 292 Mizhnarodni ekonomichni vidnosyny. Osvitnia prohrama «Mizhnarodni ekonomichni vidnosyny». Vinnytsia: Donetskyi natsionalnyi universytet imeni Vasylia Stusa.

- Jamshidi, J., Kayani, A., Iravani, P., Maropoulos, P. G., Summers, M. D. (2009). Manufacturing and assembly automation by integrated metrology systems for aircraft wing fabrication. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 224 (1), 25–36. doi: https://doi.org/10.1243/09544054jem1280

- Virchenko, H. A., Pasichnyk, D. D. (2014). Osoblyvosti niveliuvannia litakiv za dopomohoiu lazernoi koordynatno-vymiriuvalnoi mashyny. Informatsiini systemy, mekhanika ta keruvannia, 10, 152–159.

- Vorobiov, I., Maiorova, K., Voronko, I., Skyba, O., Komisarov, O. (2024). Mathematical models creation for calculating dimensional accuracy at the construction stages of an analytical standard using the chain method. Technology Audit and Production Reserves, 1 (1 (75)), 26–34. doi: https://doi.org/10.15587/2706-5448.2024.297732

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Borys Lupkin, Kateryna Maiorova, Oleksiy Pavlenko, Sergey Tolstoy, Iryna Voronko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.