Розробка моделі тертя типу «Прилипання-ковзання» для дискретно-елементного моделювання

DOI:

https://doi.org/10.15587/2706-5448.2024.310428Ключові слова:

кулонівське тертя, статика, динаміка, прилипання-ковзання, метод дискретних елементів, м’який контакт, швидкість зсувуАнотація

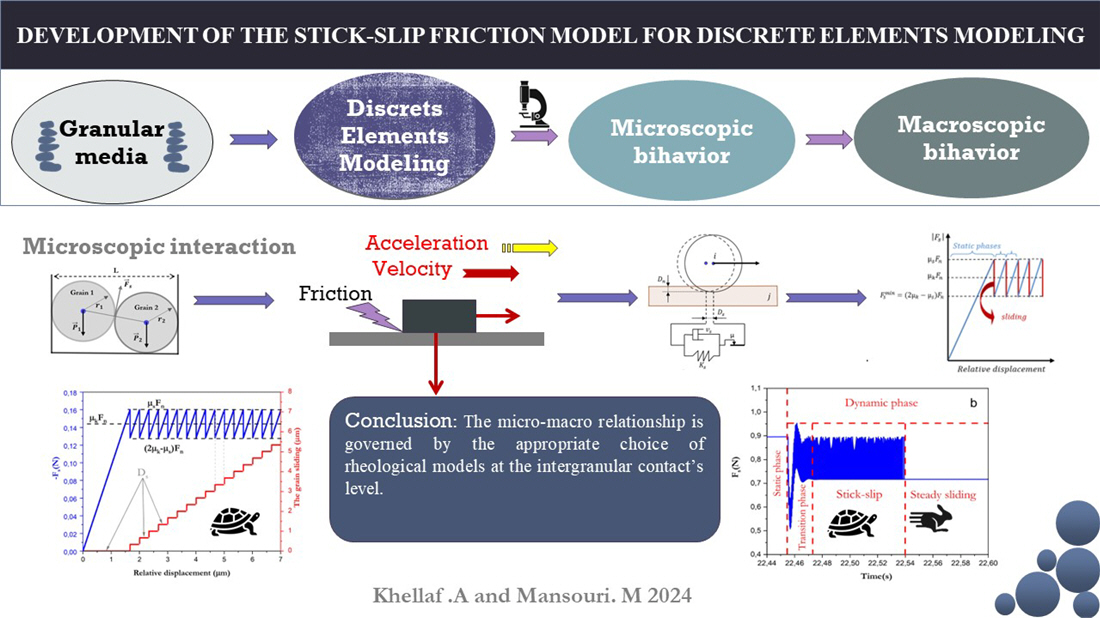

Об’єктом дослідження є модель міжзернового тертя для використання в дискретно-елементному моделюванні механічної поведінки гранульованих матеріалів у статичних і динамічних умовах. Оскільки в цьому підході зерна моделюються незалежними елементами, що взаємодіють через контактні сили, вибір моделей контактних сил, і зокрема для тангенціальної складової (тертя), є найважливішим завданням для отримання найбільш реалістичної макроскопічної поведінки. Існує багато моделей тертя, які добре працюють в динамічних режимах, але не здатні моделювати механічну поведінку в статичних або квазістатичних режимах. У цій роботі було запропоновано модель міжзеренного тертя, засновану на кулонівській регуляризованій моделі тертя, яка враховує явище прилипання, що з'являється при низьких швидкостях ковзання на контакті. Три різні приклади були розроблені та змодельовані для того, щоб продемонструвати стійкість моделі в різних ситуаціях, включаючи статичні, квазістатичні та динамічні режими. Перший – базовий приклад, що складається з поступального руху зерна по плоскій поверхні з відносно низькою постійною швидкістю. Цей приклад дозволив зафіксувати явище прилипання-ковзання. Другий приклад представляє зерно, що знаходиться під дією власної ваги та підтримується в основному силами тертя. Цей приклад показує, що модель добре працює як в квазістатичному, так і в статичному режимах. Третій приклад складається із зернини, що ковзає по пластині та піддається прискореному руху. Він показав вплив швидкості тертя на виникнення прилипання, а також еволюцію сили тертя зі швидкістю ковзання. Отримані результати показали, що модель ефективно описує поведінку зсуву в різних режимах. Таким чином, вона може бути використана в дискретно-елементному моделюванні гранульованих матеріалів як в статичних, так і в динамічних умовах. Оскільки в цій роботі модель сформульовано у 2D, було б цікаво розробити загальну 3D модель формулювання, щоб її можна було легко застосувати в 3D моделюванні.

Посилання

- Cundall, P. A., Strack, O. D. L. (1979). A discrete numerical model for granular assemblies. Géotechnique, 29 (1), 47–65. https://doi.org/10.1680/geot.1979.29.1.47

- Hong, D. C., McLennan, J. A. (1992). Molecular dynamics simulations of hard sphere granular particles. Physica A: Statistical Mechanics and Its Applications, 187 (1-2), 159–171. https://doi.org/10.1016/0378-4371(92)90416-n

- Jean, M. (1999). The non-smooth contact dynamics method. Computer Methods in Applied Mechanics and Engineering, 177 (3-4), 235–257. https://doi.org/10.1016/s0045-7825(98)00383-1

- Haff, P. K., Werner, B. T. (1986). Computer simulation of the mechanical sorting of grains. Powder Technology, 48 (3), 239–245. https://doi.org/10.1016/0032-5910(86)80048-1

- Kruggel-Emden, H., Simsek, E., Rickelt, S., Wirtz, S., Scherer, V. (2007). Review and extension of normal force models for the Discrete Element Method. Powder Technology, 171 (3), 157–173. https://doi.org/10.1016/j.powtec.2006.10.004

- Malone, K. F., Xu, B. H. (2008). Determination of contact parameters for discrete element method simulations of granular systems. Particuology, 6 (6), 521–528. https://doi.org/10.1016/j.partic.2008.07.012

- Machado, M., Moreira, P., Flores, P., Lankarani, H. M. (2012). Compliant contact force models in multibody dynamics: Evolution of the Hertz contact theory. Mechanism and Machine Theory, 53, 99–121. https://doi.org/10.1016/j.mechmachtheory.2012.02.010

- Suhr, B., Six, K. (2016). Friction phenomena and their impact on the shear behaviour of granular material. Computational Particle Mechanics, 4 (1), 23–34. https://doi.org/10.1007/s40571-016-0119-2

- Filippo, M., Di Felice, R. (2021). On the Influence of Contact Models on Friction Forces in Discrete Element Method Simulations. Chemical Engineering Transactions, 86, 811–816.

- Man, T., Zhang, P., Ge, Z., Galindo-Torres, S. A., Hill, K. M. (2022). Friction-dependent rheology of dry granular systems. Acta Mechanica Sinica, 39 (1). https://doi.org/10.1007/s10409-022-22191-x

- Luding, S., Clément, E., Blumen, A., Rajchenbach, J., Duran, J. (1994). Onset of convection in molecular dynamics simulations of grains. Physical Review E, 50 (3), R1762–R1765. https://doi.org/10.1103/physreve.50.r1762

- Luding, S. (2008). Cohesive, frictional powders: contact models for tension. Granular Matter, 10 (4), 235–246. https://doi.org/10.1007/s10035-008-0099-x

- Führer, F., Brendel, L., Wolf, D. E. (2024). Correction of the spring-dashpot-slider model. Granular Matter, 26 (2). https://doi.org/10.1007/s10035-024-01424-4

- Mindlin (1949). Compliance Of Elastic Bodies In Contact. Available at: https://www.researchgate.net/profile/Valentin-Popov-2/post/Does-anyone-have-an-electronic-copy-of-1949-paper-by-Mindlin-Compliance-of-Elastic-Bodies-in-Contact-JAM-16-1949/attachment/5fcfedf53b21a2000160b8d3/AS%3A966581471440897%401607462389742/download/Mindlin_1949_ComplianceOfElasticBodiesInContact.pdf

- Walton, O. R., Braun, R. L. (1986). Viscosity, granular‐temperature, and stress calculations for shearing assemblies of inelastic, frictional disks. Journal of Rheology, 30 (5), 949–980. https://doi.org/10.1122/1.549893

- Shäfer, J., Dippel, S., Wolf, D. E. (1996). Force Schemes in Simulations of Granular Materials. Journal de Physique I, 6 (1), 5–20. https://doi.org/10.1051/jp1:1996129

- Heslot, F., Baumberger, T., Perrin, B., Caroli, B., Caroli, C. (1994). Creep, stick-slip, and dry-friction dynamics: Experiments and a heuristic model. Physical Review E, 49 (6), 4973–4988. https://doi.org/10.1103/physreve.49.4973

- Bengisu, M. T., Akay, A. (1999). Stick–slip oscillations: Dynamics of friction and surface roughness. The Journal of the Acoustical Society of America, 105 (1), 194–205. https://doi.org/10.1121/1.424580

- Togo, T., Shimamoto, T. (2012). Energy partition for grain crushing in quartz gouge during subseismic to seismic fault motion: An experimental study. Journal of Structural Geology, 38, 139–155. https://doi.org/10.1016/j.jsg.2011.12.014

- Persson, B. N. J. (2013). Sliding Friction: Physical Principles and Applications. Springer Science & Business Media.

- Berman, A. D., Ducker, W. A., Israelachvili, J. N. (1996). Origin and Characterization of Different Stick−Slip Friction Mechanisms. Langmuir, 12 (19), 4559–4563. https://doi.org/10.1021/la950896z

- Dunham, E. M., Rice, J. R. (2008). Earthquake slip between dissimilar poroelastic materials. Journal of Geophysical Research: Solid Earth, 113 (B9). https://doi.org/10.1029/2007jb005405

- Singh, T. N., Verma, A. K., Kumar, T., Dutt, A. (2011). Influence of shear velocity on frictional characteristics of rock surface. Journal of Earth System Science, 120 (1), 183–191. https://doi.org/10.1007/s12040-011-0009-1

- Yang, C.-M., Yu, W.-L., Dong, J.-J., Kuo, C.-Y., Shimamoto, T., Lee, C.-T., Togo, T., Miyamoto, Y. (2014). Initiation, movement, and run-out of the giant Tsaoling landslide – What can we learn from a simple rigid block model and a velocity–displacement dependent friction law? Engineering Geology, 182, 158–181. https://doi.org/10.1016/j.enggeo.2014.08.008

- Armstrong-Hélouvry, B., Dupont, P., De Wit, C. C. (1994). A survey of models, analysis tools and compensation methods for the control of machines with friction. Automatica, 30 (7), 1083–1138. https://doi.org/10.1016/0005-1098(94)90209-7

- Luding, S., Clément, E., Blumen, A., Rajchenbach, J., Duran, J. (1994). Anomalous energy dissipation in molecular-dynamics simulations of grains: The «detachment» effect. Physical Review E, 50 (5), 4113–4122. https://doi.org/10.1103/physreve.50.4113

- Ketterhagen, W. R., Curtis, J. S., Wassgren, C. R. (2005). Stress results from two-dimensional granular shear flow simulations using various collision models. Physical Review E, 71 (6). https://doi.org/10.1103/physreve.71.061307

- Teufelsbauer, H., Wang, Y., Pudasaini, S. P., Borja, R. I., Wu, W. (2011). DEM simulation of impact force exerted by granular flow on rigid structures. Acta Geotechnica, 6 (3), 119–133. https://doi.org/10.1007/s11440-011-0140-9

- Mansouri, M., El Youssoufi, M. S., Nicot, F. (2016). Numerical simulation of the quicksand phenomenon by a 3D coupled Discrete Element – Lattice Boltzmann hydromechanical model. International Journal for Numerical and Analytical Methods in Geomechanics, 41 (3), 338–358. https://doi.org/10.1002/nag.2556

- Gallas, J. A. C., Herrmann, H. J., Sokołowski, S. (1992). Molecular dynamics simulation of powder fluidization in two dimensions. Physica A: Statistical Mechanics and Its Applications, 189 (3-4), 437–446. https://doi.org/10.1016/0378-4371(92)90055-u

- Melin, S. (1994). Wave propagation in granular assemblies. Physical Review E, 49 (3), 2353–2361. https://doi.org/10.1103/physreve.49.2353

- Wei, H., Li, M., Li, Y., Ge, Y., Saxén, H., Yu, Y. (2019). Discrete Element Method (DEM) and Experimental Studies of the Angle of Repose and Porosity Distribution of Pellet Pile. Processes, 7 (9), 561. https://doi.org/10.3390/pr7090561

- Wei, S., Wei, H., Saxen, H., Yu, Y. (2022). Numerical Analysis of the Relationship between Friction Coefficient and Repose Angle of Blast Furnace Raw Materials by Discrete Element Method. Materials, 15 (3), 903. https://doi.org/10.3390/ma15030903

- Dhaouadi, W., Marteau, E., Kolvenbach, H., Choukroun, M., Molaro, J. L., Hodyss, R., Schulson, E. M. (2021). Discrete element modeling of planetary ice analogs: mechanical behavior upon sintering. Granular Matter, 24 (1). https://doi.org/10.1007/s10035-021-01167-6

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Abdelghani Khellaf, Mouloud Mansouri

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.