Determination of the temperature of mineral fertiliser granules after contact with the air in a granulation tower

DOI:

https://doi.org/10.15587/2706-5448.2024.310855Keywords:

granulation tower, heat transfer coefficient, rotating vibrating granulator, mineral fertilizers, thermodynamic processes, hydrodynamic parametersAbstract

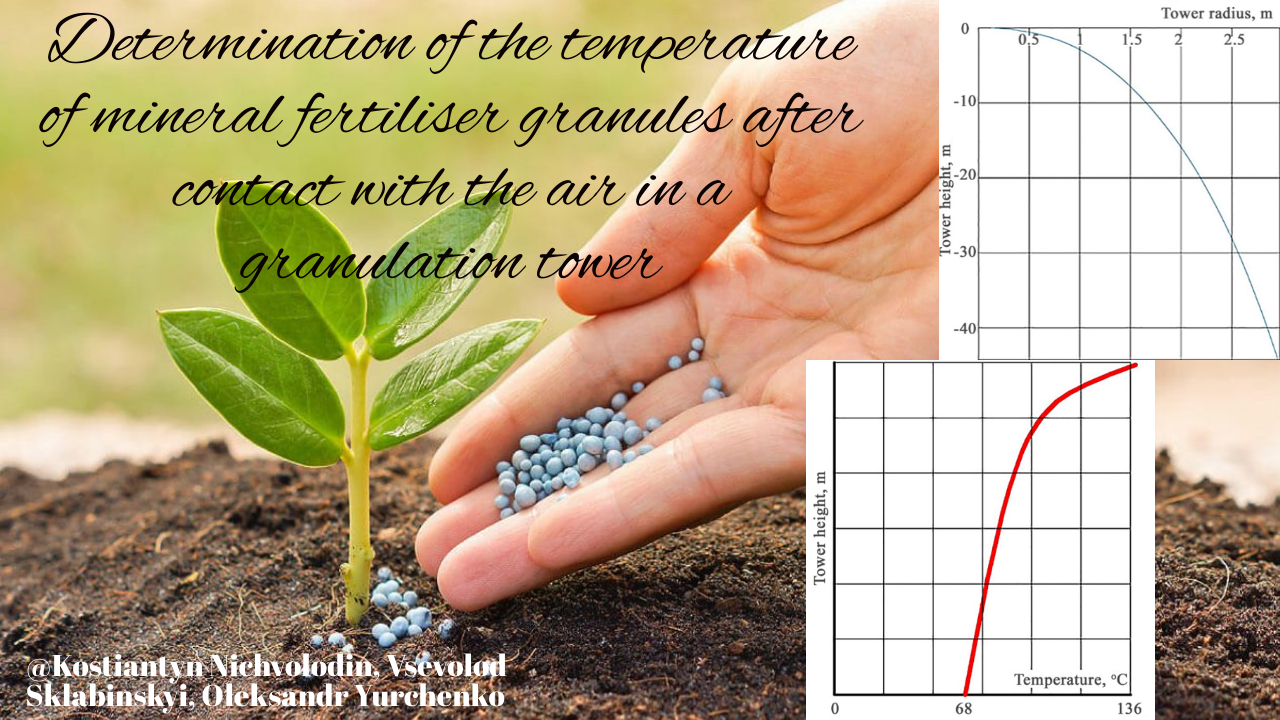

The object of research is the process of cooling mineral fertilizer granules in a granulation tower. The main problem that was solved was the analysis of the temperature mode of cooling the granules to increase their strength and quality, as well as to reduce the probability of their destruction during storage and transportation.

The design of a rotating vibrating granulator (RVG) and a mathematical model for calculating the temperature of granules and air at different stages of the granulation process are presented. Reynolds, Peclet and Prandtl criteria are used to describe hydrodynamic and thermodynamic processes.

In the course of the work, a calculation model and the possibility of predicting the final temperature of mineral fertilizer granules were created, which allows to avoid negative consequences, such as a decrease in the strength of the granules and their destruction during shipment, transportation and introduction into the soil. Improving the technological performance of the granulation tower, in particular the temperature regimes of granule cooling, contributes to the improvement of product quality. The calculation model allows to adjust the process parameters to ensure the formation of granules with specified properties that meet modern requirements for the monodisperse composition of mineral fertilizer granules.

Results were obtained that show the influence of hydrodynamic and thermodynamic factors on the process of cooling and crystallization of granules. This is due to the use of a rotating vibrating granulator, which ensures uniform distribution of liquid droplets across the cross section of the tower and their effective cooling due to contact with the air flow.

The results can be used in practice to improve the operation of granulation towers in the production of mineral fertilizers, which allows to improve the quality of products and improve their storage and use. Compared to similar methods, the use of the proposed models provides increased strength and uniformity of granules, which are key advantages in conditions of large-scale production of fertilizers.

References

- Skydanenko, M. S. (2014). Hidromekhanichni pokaznyky prystroiv dlia otrymannia monodyspersnykh krapel ta hranul. PhD dissertation.

- Islamova, A. (2018). Experimental determination of the heat transfer coefficient during evaporation and boiling of thin liquid film. MATEC Web of Conferences, 194, 01022. https://doi.org/10.1051/matecconf/201819401022

- Vossel, T., Wolff, N., Pustal, B., Bührig-Polaczek, A., Ahmadein, M. (2021). Heat Transfer Coefficient Determination in a Gravity Die Casting Process with Local Air Gap Formation and Contact Pressure Using Experimental Evaluation and Numerical Simulation. International Journal of Metalcasting, 16 (2), 595–612. https://doi.org/10.1007/s40962-021-00663-y

- Moreira, T. A., Colmanetti, A. R. A., Tibiriçá, C. B. (2019). Heat transfer coefficient: a review of measurement techniques. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 41 (6). https://doi.org/10.1007/s40430-019-1763-2

- Wu, C., Xu, W., Wan, S., Luo, C., Lin, Z., Jiang, X. (2022). Determination of Heat Transfer Coefficient by Inverse Analyzing for Selective Laser Melting (SLM) of AlSi10Mg. Crystals, 12 (9), 1309. https://doi.org/10.3390/cryst12091309

- Petrich, C., Arntsen, M., Dayan, H., Nilsen, R. (2013). Heat Transfer in a Bed of Dry Iron Ore Pellets. ISIJ International, 53 (4), 723–725. https://doi.org/10.2355/isijinternational.53.723

- Chung, C.-H., Yang, K.-S., Chien, K.-H., Jeng, M.-S., Lee, M.-T. (2014). Heat Transfer Characteristics in High Power LED Packaging. Smart Science, 2 (1), 1–6. https://doi.org/10.1080/23080477.2014.11665596

- Yurchenko, O., Sklabinskyi, V., Ochowiak, M., Ostroha, R., Gusak, O. (2022). Rational Choice of a Basket for the Rotational Vibropriller. Journal of Engineering Sciences, 9 (1), F16–F20. https://doi.org/10.21272/jes.2022.9(1).f3

- Coulson, J. M., Richardson, J. F. (1999). Chemical Engineering. Vol. 1. Elsevier.

- Chepurnyi, M. M., Tkachenko, S. Y. (2004). Osnovy tekhnichnoi termodynamiky. Vinnytsia: Podillia-2000, 358.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Vsevolod Sklabinskyi, Kostiantyn Nichvolodin, Oleksandr Yurchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.