Improvement of a microfilter prototype and its realization: chemical applications

DOI:

https://doi.org/10.15587/2706-5448.2025.322592Keywords:

MEMS, NEMS, MET, 3D printer, microfilter, microfabrication, chemical microreactor, microseparation unit, air and liquid filtration, human healthAbstract

The object of this research is microfilters. This study aims to develop a microfilter that can be used, for example, for air or water filtration as traditional applications. The closed indoor environments demand the control of the air quality for the health of humans who work there. The implementation of different technologies as MicroElectroMechanical Systems (MEMS), NanoElectroMechanical Systems (NEMS) and MicroEquipment Technology (MET) for microcomponents production is analyzed. The advantages and disadvantages of these technologies are described. MET was used to produce and develop microfilter structure.

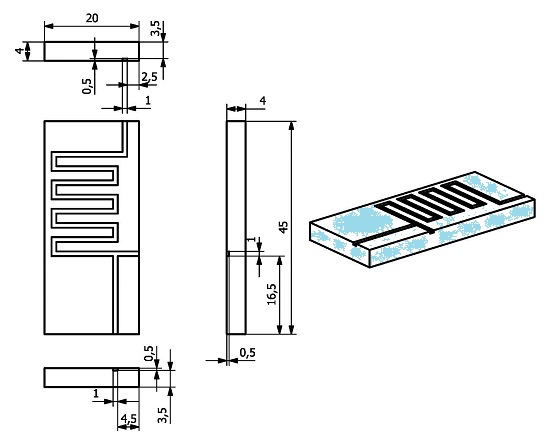

The structffure and model of the microfilter is presented. The problem to be solved is connected with microfilter structure simplification and preparation it for the use of new technologies for their production. For its realization the 3D printer was used. 3D printers are the equipment that realizes an additive technology that has been actively developed in recent years. From computer 3D model it is possible to build the 3D prototype. The essence of the results is the possibility of mass production of microfilters. Different possible applications, not only filtration of air and liquid are described, but applications in chemistry for microreactions module and microseparation units.

It was compared new microfilter design with our previous prototype of microfilter developed and produced using the MET. The MET has advantage that it works with various materials and not just those used in microelectronics. Their tests and investigations demonstrated that the microfilters can be used in practice. New prototype was made by 3D printer. Comparative assessment of the first microfilter prototype and new prototype shows that the new prototype has a simplified structure and is easier to manufacture. One of the most interesting areas of their applications is for chemical microreactors. It is one of the new, interesting and promising areas of application.

Supporting Agency

- This research was partly supported by the project UNAM-DGAPA-PAPIIT IT 102320.

References

- Trimmer, W. S. (1997). Micromechanics and MEMS. Classical and Seminal Papers to 1990. New York: IEEE Press.

- Arab, A., Feng, Q. (2014). Reliability research on micro- and nano-electromechanical systems: a review. The International Journal of Advanced Manufacturing Technology, 74 (9-12), 1679–1690. https://doi.org/10.1007/s00170-014-6095-x

- Guo, H., Lou, L., Chen, X., Lee, C. (2012). PDMS-Coated Piezoresistive NEMS Diaphragm for Chloroform Vapor Detection. IEEE Electron Device Letters, 33 (7), 1078–1080. https://doi.org/10.1109/led.2012.2195152

- Fan, X., Forsberg, F., Smith, A. D., Schröder, S., Wagner, S., Rödjegård, H. et al. (2019). Graphene ribbons with suspended masses as transducers in ultra-small nanoelectromechanical accelerometers. Nature Electronics, 2 (9), 394–404. https://doi.org/10.1038/s41928-019-0287-1

- Kussul, E. M., Rachkovskij, D. A., Baidyk, T. N., Talayev, S. A. (1996). Micromechanical engineering: a basis for the low-cost manufacturing of mechanical microdevices using microequipment. Journal of Micromechanics and Microengineering, 6 (4), 410–425. https://doi.org/10.1088/0960-1317/6/4/008

- Kussul, E., Baidyk, T., Ruiz-Huerta, L., Caballero-Ruiz, A., Velasco, G., Kasatkina, L. (2002). Development of micromachine tool prototypes for microfactories. Journal of Micromechanics and Microengineering, 12 (6), 795–812. https://doi.org/10.1088/0960-1317/12/6/311

- Kussul, E., Baidyk, T., Wunsch, D. C. (2010). Neural Networks and Micromechanics. Berlin, Heidelberg: Springer, 210. https://doi.org/10.1007/978-3-642-02535-8

- Ko, D.-H., Gyak, K.-W., Kim, D.-P. (2017). Emerging Microreaction Systems Based on 3D Printing Techniques and Separation Technologies. Journal of Flow Chemistry, 7 (3-4), 72–81. https://doi.org/10.1556/1846.2017.00013

- Romão Bineli, A., Gimenez Peres, A., Luiz Jardini, A., Maciel Filho, R. (2011). Direct metal laser sintering (DMLS): technology for design and construction of microreactors. 6th Brazilian conference on manufacturing engineering. Brazil.

- Scotti, G., Nilsson, S. M. E., Haapala, M., Pöhö, P., Boije af Gennäs, G. et al. (2017). A miniaturised 3D printed polypropylene reactor for online reaction analysis by mass spectrometry. Reaction Chemistry & Engineering, 2 (3), 299–303. https://doi.org/10.1039/c7re00015d

- Dragone, V., Sans, V., Rosnes, M. H., Kitson, P. J., Cronin, L. (2013). 3D-printed devices for continuous-flow organic chemistry. Beilstein Journal of Organic Chemistry, 9, 951–959. https://doi.org/10.3762/bjoc.9.109

- Riche, C. T., Roberts, E. J., Gupta, M., Brutchey, R. L., Malmstadt, N. (2016). Flow invariant droplet formation for stable parallel microreactors. Nature Communications, 7 (1). https://doi.org/10.1038/ncomms10780

- Jönsson, A., Svejdal, R. R., Bøgelund, N., Nguyen, T. T. T. N., Flindt, H., Kutter, J. P. et al. (2017). Thiol-ene Monolithic Pepsin Microreactor with a 3D-Printed Interface for Efficient UPLC-MS Peptide Mapping Analyses. Analytical Chemistry, 89 (8), 4573–4580. https://doi.org/10.1021/acs.analchem.6b05103

- Yang, Y., Li, X., Zheng, X., Chen, Z., Zhou, Q., Chen, Y. (2017). 3D‐Printed Biomimetic Super‐Hydrophobic Structure for Microdroplet Manipulation and Oil/Water Separation. Advanced Materials, 30 (9). https://doi.org/10.1002/adma.201704912

- Tabassum, T., Iloska, M., Scuereb, D., Taira, N., Jin, C., Zaitsev, V. et al. (2018). Development and Application of 3D Printed Mesoreactors in Chemical Engineering Education. Journal of Chemical Education, 95 (5), 783–790. https://doi.org/10.1021/acs.jchemed.7b00663

- Zhang, L., Zhu, Z., Liu, B., Li, C., Yu, Y., Tao, S., Li, T. (2019). Fluorescent Fluid in 3D‐Printed Microreactors for the Acceleration of Photocatalytic Reactions. Advanced Science, 6 (13). https://doi.org/10.1002/advs.201900583

- Neumaier, J. M., Madani, A., Klein, T., Ziegler, T. (2019). Low-budget 3D-printed equipment for continuous flow reactions. Beilstein Journal of Organic Chemistry, 15, 558–566. https://doi.org/10.3762/bjoc.15.50

- Sundarrajan, S., Tan, K. L., Lim, S. H., Ramakrishna, S. (2014). Electrospun Nanofibers for Air Filtration Applications. Procedia Engineering, 75, 159–163. https://doi.org/10.1016/j.proeng.2013.11.034

- Wlodarczyk, K., Carter, R., Jahanbakhsh, A., Lopes, A., Mackenzie, M., Maier, R. et al. (2018). Rapid Laser Manufacturing of Microfluidic Devices from Glass Substrates. Micromachines, 9 (8), 409. https://doi.org/10.3390/mi9080409

- Rodríguez Andrade, J. (2018). Diseño de microcentro de maquinado para fabricación de microfiltros de aire. [Tesis de Maestría en Ingeniería Eléctrica].

- Rodriguez Andrade, J., Kussul, E., Baydyk, T. (2020). Microchannel filter for air purification. Open Physics, 18 (1), 241–254. https://doi.org/10.1515/phys-2020-0153

- Ley de Poiseuille. HyperPhysics. Available at: http://hyperphysics.phy-astr.gsu.edu/hbasees/ppois.html Last accessed: 09.02.2025

- Curso Hidraulica (2012). Propiedades geométricas de los canales. Available at: http://hidraulicaucentral.blogspot.com/2012/05/variables-y-fenomenos-hidraulicos.html Last accessed: 09.02.2025

- An open-source 3d print software. Robots in the sun. Available at: http://robotsinthesun.org/monkeyprint-an-open-source-3d-print-software/

- FDM vs. SLA vs. SLS: 3D Printing Technology Comparison. Available at: https://formlabs.com/blog/fdm-vs-sla-vs-sls-how-to-choose-the-right-3d-printing-technology/?srsltid=AfmBOorzPrAsINci6DjihgPM5pvvxROR-7MWEdoaZzON_3PTJxvO5EQA Last accessed: 02.05.2025

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Tetyana Baydyk, Masuma Mammadova, Graciela Velasco Herrera, Ernst Kussul

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.