Construction of a kinetic equation of carbon removal for controlling steel melting in the metallurgical system “cupola furnace – small converter”

DOI:

https://doi.org/10.15587/2706-5448.2025.325695Keywords:

cupola melting, converter, oxygen blowing, sharp blast in a cupola furnace, kinetic equationsAbstract

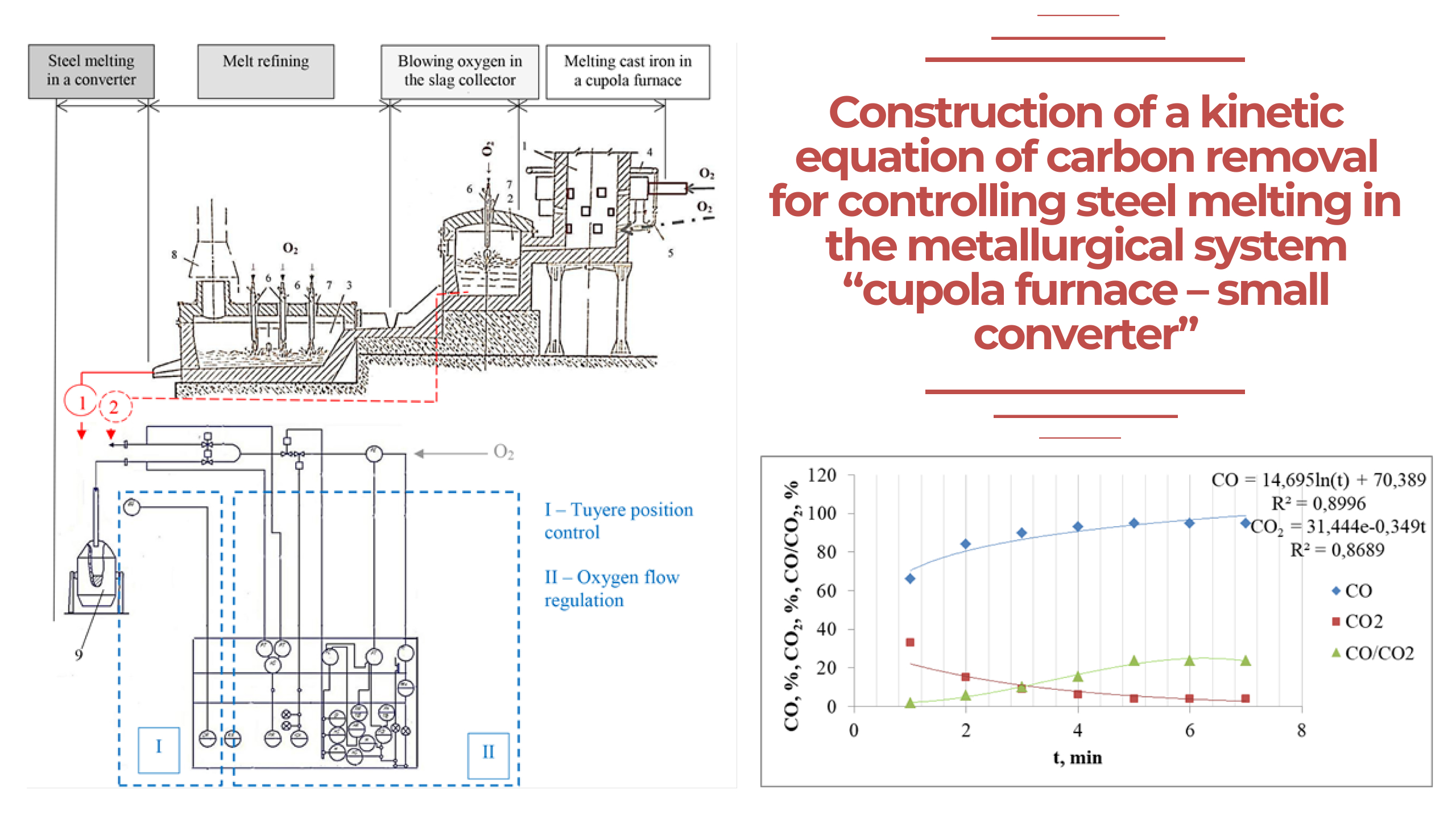

The object of research in the paper is the process of steelmaking in a small converter, which works in tandem with a cupola furnace.

The existing problem is that the control of the process of obtaining steel in an oxygen converter is complicated by the need to determine in real time the current chemical composition of the melt, in particular carbon. This is due to the fact that the rate of carbon removal is too high, as a result of which the process of carbon removal is transient. Therefore, it is too difficult to implement regulation based on feedback on continuous measurement.

The presence of the specified problem requires solutions related to the possibilities of developing or improving software control of the process.

It is shown that in certain sections of the process within each time section of oxygen purging of the melt in the converter, the kinetic curve has a linear form with a constant coefficient value in front of the inlet mine. But the value of the initial coefficient for each equation that describes the process within its limits changes. This allows to state that in case of a change in the initial condition, the kinetic curves shift relative to each other in parallel. On this basis, a system of equations has been constructed that describes the process of carbon removal in a small oxygen converter that receives liquid iron from a cupola furnace.

It has been shown that to use the obtained system of equations, it is necessary to know the initial carbon content in the melt discharged from the cupola furnace, and it depends on the method of oxygen supply to the cupola furnace. Based on the modeling of this process in two variants – using a “sharp blow” and supplying oxygen to the air blown into the tuyeres, a nomogram has been constructed. It allows to determine the initial carbon content for the practical use of the obtained system of equations.

Using the obtained system makes it possible to determine the time after which oxygen cutoff should be made. This will allow to decide to implement software control of the melt blowing process in the converter.

The presented study will be useful for machine-building enterprises that have foundry shops in their structure, where cast iron is smelted for the manufacture of castings.

References

- Ristiana, R., Nurjaman, F., Yunus, M. (2013). Fuzzy Temperature Control for Melting Metals of Mini Cupola Furnaces. Research on Precision Instrument and Machinery, 2 (2).

- Isnugroho, K., Birawidha, D. C. (2018). The production of pig iron from crushing plant waste using hot blast cupola. Alexandria Engineering Journal, 57 (1), 427–433. https://doi.org/10.1016/j.aej.2016.11.004

- Larsen, E. D., Clark, D. E., Moore, K. L., King, P. E. (1997). Intelligent control of Cupola Melting. Available at: https://pdfs.semanticscholar.org/56c2/96af1d56d5cd963a5bcc38635142e5fa1968.pdf

- Moore, K. L., Abdelrahman, M. A., Larsen, E., Clark, D., King, P. (1998). Experimental control of a cupola furnace. Proceedings of the 1998 American Control Conference. ACC (IEEE Cat. No.98CH36207), 6, 3816–3821. https://doi.org/10.1109/acc.1998.703360

- Mahmoud, W. H., Abdelrahman, M., Haggard, R. L. (2004). Field programmable gate arrays implementation of automated sensor self-validation system for cupola furnaces. Computers & Industrial Engineering, 46 (3), 553–569. https://doi.org/10.1016/j.cie.2004.02.001

- Nikolaiev, D. (2024). Construction of a cupola information profile for further modeling for the purpose of controlling melting processes. ScienceRise, 2, 3–14. https://doi.org/10.21303/2313-8416.2024.003674

- Demin, D., Frolova, L. (2024). Construction of a logical-probabilistic model of casting quality formation for managing technological operations in foundry production. EUREKA: Physics and Engineering, 6, 104–118. https://doi.org/10.21303/2461-4262.2024.003518

- Demin, D. (2012). Synthesis of optimal temperature regulator of electroarc holding furnace bath. Scientific Bulletin of National Mining University, 6, 52–58.

- Demin, D. (2014). Mathematical description typification in the problems of synthesis of optimal controller of foundry technological parameters. Eastern-European Journal of Enterprise Technologies, 1 (4 (67)), 43–56. https://doi.org/10.15587/1729-4061.2014.21203

- Demin, D. (2014). Computer-integrated electric-arc melting process control system. Eastern-European Journal of Enterprise Technologies, 2 (9 (68)), 18–23. https://doi.org/10.15587/1729-4061.2014.23512

- Demin, D. (2017). Synthesis of optimal control of technological processes based on a multialternative parametric description of the final state. Eastern-European Journal of Enterprise Technologies, 3 (4 (87)), 51–63. https://doi.org/10.15587/1729-4061.2017.105294

- Demin, D. (2019). Development of «whole» evaluation algorithm of the control quality of “cupola – mixer” melting duplex process. Technology Audit and Production Reserves, 3 (1 (47)), 4–24. https://doi.org/10.15587/2312-8372.2019.174449

- Demin, D. (2023). Experimental and industrial method of synthesis of optimal control of the temperature region of cupola melting. EUREKA: Physics and Engineering, 2, 68–82. https://doi.org/10.21303/2461-4262.2023.002804

- Jopkiewicz, A., Podrzucki, C. (2007). Tendencies to the Improvement of the Cupola Process. Archives of foundry engineering, 13 (3), 61–70.

- Powell, W. L., Druschitz, A. P., Frost, J. (2008). Cupola Furnaces. Casting, 99–107. https://doi.org/10.31399/asm.hb.v15.a0005197

- Aristizábal, R. E., Pérez, P. A., Katz, S., Bauer, M. E. (2014). Studies of a Quenched Cupola. International Journal of Metalcasting, 8 (3), 13–22. https://doi.org/10.1007/bf03355586

- Ajah, S. A., Idorenyin, D., Nwokenkwo, U. C., Nwigwe, U. S., Ezurike, B. O. (2021). Thermal Analysis of a Conventional Cupola Furnace with Effects of Excess Air on the Flue Gases Specific Heat. Journal of Materials and Environmental Science, 12 (2), 192–204.

- Demin, D., Domin, O. (2021). Adaptive technology for constructing the kinetic equations of reduction reactions under conditions of a priori uncertainty. EUREKA: Physics and Engineering, 4, 14–29. https://doi.org/10.21303/2461-4262.2021.001959

- Demin, D. (2013). Adaptive modeling in problems of optimal control search termovremennoy cast iron. Eastern-European Journal of Enterprise Technologies, 6 (4 (66)), 31–37. https://doi.org/10.15587/1729-4061.2013.19453

- Luis, C. J., Álvarez, L., Ugalde, M. J., Puertas, I. (2002). A technical note cupola efficiency improvement by increasing air blast temperature. Journal of Materials Processing Technology, 120 (1-3), 281–289. https://doi.org/10.1016/s0924-0136(01)01053-6

- Jezierski, J., Janerka, K. (2011). Selected Aspects of Metallurgical and Foundry Furnace Dust Utilization. Polish Journal of Environmental Studies, 20 (1), 101–105.

- Nikolaiev, D., Selivorstov, V., Dotsenko, Y., Dzevochko, O., Pereverzieva, A., Dzevochko, A. (2025). Identification of temperature in cupola furnace based on the construction of the “slag composition – slag viscosity” model. Technology Audit and Production Reserves, 1 (1 (81)), 29–33. https://doi.org/10.15587/2706-5448.2025.322458

- Penziev, P., Lavryk, Y. (2023). Diagnostics of the temperature condition of cast iron melting in induction furnaces by the content of SiO2 and CaO in slag. ScienceRise, 1, 14–20. https://doi.org/10.21303/2313-8416.2024.003558

- Demin, D. (2020). Constructing the parametric failure function of the temperature control system of induction crucible furnaces. EUREKA: Physics and Engineering, 6, 19–32. https://doi.org/10.21303/2461-4262.2020.001489

- Stanovska, I., Duhanets, V., Prokopovych, L., Yakhin, S. (2021). Classification rule for determining the temperature regime of induction gray cast iron. EUREKA: Physics and Engineering, 1, 60–66. https://doi.org/10.21303/2461-4262.2021.001604

- Demin, D. (2025). Optimization of parameters of the cupola melting by the criterion of the maximum cast iron temperature. EUREKA: Physics and Engineering, 2, 00–00. https://doi.org/10.21303/2461-4262.2025.003712

- Tang, Y., Fabritius, T., Härkki, J. (2005). Mathematical modeling of the argon oxygen decarburization converter exhaust gas system at the reduction stage. Applied Mathematical Modelling, 29 (5), 497–514. https://doi.org/10.1016/j.apm.2004.09.011

- Park, J., Kwon, S.-K., Lee, J.-E., Kang, Y., Park, J. H. (2023). Effect of oxygen blowing on the competitive removal rate of silicon and iron from molten copper. Journal of Materials Research and Technology, 23, 4634–4641. https://doi.org/10.1016/j.jmrt.2023.02.106

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Dmytro Makarenko, Tetiana Selivorstova, Yuriy Dotsenko, Iryna Osypenko, Oleksandr Dzevochko, Alevtyna Pereverzieva, Alona Dzevochko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.