Determination on energy efficiency in corn grain drying

DOI:

https://doi.org/10.15587/2706-5448.2025.326080Keywords:

corn grain drying, biomass, grain dryer, energy efficiency, biofuel boiler, alternative energy sourcesAbstract

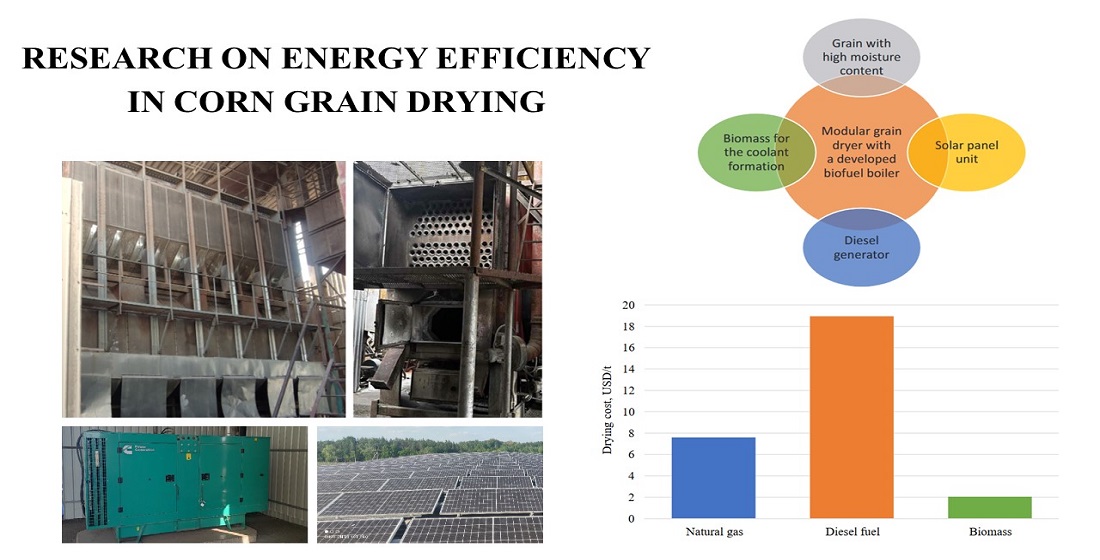

The object of research is the technological processes of corn grain drying, energy plants. One of the most problematic areas for agricultural producers is providing energy for technological processes of bringing grain material to the indicators of product sales. And during the war and post-war period in Ukraine, this requires non-standard approaches and ways of implementation. Therefore, for operation in autonomous mode, the technology involves the use of biomass, electricity from solar panels and/or a diesel generator to supply the coolant to the grain drying zone. The availability of biomass is ensured by cleaning grain material after harvesting and crop residues.

The study examined the technology of corn grain drying in “Agrotechservice” LLC of the Poltava district of the Poltava region (Ukraine) using the Saphir 2134 modular grain dryer with an improved biomass boiler.

The results of studies of the operation of a grain dryer using different types of fuel (gas, diesel fuel, alternative fuel) showed that the energy consumption for reducing humidity by 1 ton-percent was: for gas – 1.5 m3; for diesel fuel – 1.8 l; for biomass – 3.4 kg. The total cost of drying on a Saphir 2134 grain dryer was obtained, which is 0.205 USD, which is 3.7 times less than when using natural gas and 9.2 times less than when using diesel fuel. This is due to the fact that the proposed technology involves the use of an improved biomass boiler and alternative energy sources. This provides the possibility of obtaining average daily savings using a grain dryer of this model with an improved biomass boiler, which will be about 1.1 thousand USD. Compared to similar corn grain drying processes, these studies have shown the economic feasibility of using biomass as an energy material for the production of thermal energy in the corn grain drying process.

References

- Gorbenko, O., Lyashenko, S., Kelemesh, A., Padalka, V., Kalinichenko, A. (2021). Waste Usage as Secondary Resources. Procedia Environmental Science, Engineering and Management, 8 (2), 417–429. Available at: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85101384718&partnerID=40&md5=0f37db7a2ed0b54f62c2d50be70d056e

- Kyrpa, M. Ya., Kulyk, V. O. (2016). Enerhooshchadni pryiomy u tekhnolohiiakh sushinnia nasinnia kukurudzy. Biuleten Instytutu silskoho hospodarstva stepovoi zony NAAN Ukrainy, 11, 82–87. Available at: http://nbuv.gov.ua/UJRN/bisg_2016_11_19

- Wu, Y., Wu, W., Han, F., Zhang, Y., Xu, Y. (2017). Intelligent Monitoring and Control of Grain Continuous Drying Process Based on Multi-parameter Corn Accumulated Temperature Model. 2017 International Conference on Smart Grid and Electrical Automation (ICSGEA), 77–80. https://doi.org/10.1109/icsgea.2017.129

- Kyrpa, M. Ya. (2017). Tekhnolohiia pisliazbyralnoi obrobky ta sushinnia zerna. Propozytsiia. Available at: https://propozitsiya.com/ua/tehnologiya-pislyazbiralnoyi-obrobki-ta-sushinnya-zerna

- Wang, G., Wu, W., Xu, W., Xu, Y., Zhang, Y., Fu, D. (2022). Exergy analysis of an electric grain drying system with internal circulation of the drying medium of corn. International Journal of Exergy, 37 (1), 102–120. https://doi.org/10.1504/ijex.2022.120127

- Amantea, R. P., Sarri, D., Rossi, G. (2024). A system dynamic modeling to evaluate fluidized bed dryers under tempering and recirculation strategies. Applied Chemical Engineering, 7 (1). https://doi.org/10.24294/ace.v7i1.3276

- Fu, D., Wu, W., Wang, G., Xu, H., Han, F., Liu, Z. (2023). Novel Method of Increased Efficiency Corn Drying on a Fixed Bed by Condensation. Foods, 12 (5), 1027. https://doi.org/10.3390/foods12051027

- Kobylianskyi, Ye. O. (2021). Increasing energy efficiency grain dryer works. Perspektyvy rozvytku mashynobuduvannia ta transportu – 2021. Vinnytsia. 383–384. Available at: https://ir.lib.vntu.edu.ua/bitstream/handle/123456789/37069/13477-48237-1-PB.pdf?sequence=1&isAllowed=y

- Wang, G.-Y., Han, F., Liu, Z., Wu, W.-F., Xu, Q.-K., Yue, Z.-F. (2023). Research on Intelligent Test System for Energy Recycling and Saving Technology of Agricultural Products Drying. Science and Technology of Cereals, Oils and Foods, 31 (2), 90–96. https://doi.org/10.16210/j.cnki.1007-7561.2023.02.012

- Heletukha, H., Drahniev, S., Zheliezna, T., Karampinis, M. (2022). Enerhiia z reshtok kukurudzy. UABIO, CERTH, 48. Available at: https://uabio.org/wp-content/uploads/2022/04/Maize-residues-to-Energy_ukr-web.pdf?utm_source=chatgpt.com

- Mondal, Md. H. T., Sarker, Md. S. H. (2024). Comprehensive energy analysis and environmental sustainability of industrial grain drying. Renewable and Sustainable Energy Reviews, 199, 114442. https://doi.org/10.1016/j.rser.2024.114442

- Shapovalenko, O. I., Yevtushenko, O. O., Yaniuk, T. I., Rybchynskyi, R. S. (2020). Sushinnia ta zberihannia zerna. Kherson: Oldi-Plius, 396.

- Pazіuk, V. (2021). Modern approaches to the solution of the problem of increasing the energy efficiency of seed grain drying. Vidnovluvana Energetika, 4 (67), 90–99. https://doi.org/10.36296/1819-8058.2021.4(67).90-99

- Kolotii, V. I., Kolotii, Yu. V., Kolotii, S. Yu., Horbenko, O. V., Lapenko, H. O., Lapenko, T. H. (2024). Pat. No. 157019 UA. Biopalyvnyi kotel dlia sushinnia zerna. MPK (2024.01): F23B 40/00, F24H 3/00. No. u202401924; declareted: 11.04.2024; published: 28.08.2024, Bul. No. 3035, 4.

- Zanko, M., Haidai, T., Sydorenko, S., Nivalova, N. (2021). Doslidzhennia yakosti sushinnia zerna kukurudzy susharkoiu modeli Stela Agrodry MDB-XN 4/15-SU v zhorstkomu rezhymi. Naukovo-tekhnichni zasady rozroblennia, vyprobuvannia ta prohnozuvannia silskohospodarskoi tekhniky i tekhnolohii. Doslidnytske, 195–201. Available at: https://nubip.edu.ua/sites/default/files/u349/zbirnik_tez_2021.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Oleksandr Gorbenko, Hryhorii Lapenko, Taras Lapenko, Samson Kolotii

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.