Розробка методики розрахунку робочого процесу роторного робочого органу машин для земляних та дорожніх робіт

DOI:

https://doi.org/10.15587/2706-5448.2025.327212Ключові слова:

роторний робочий орган, траєкторія різання, ріжучі ножі, товщина різання, абсолютна швидкість, енерговитратиАнотація

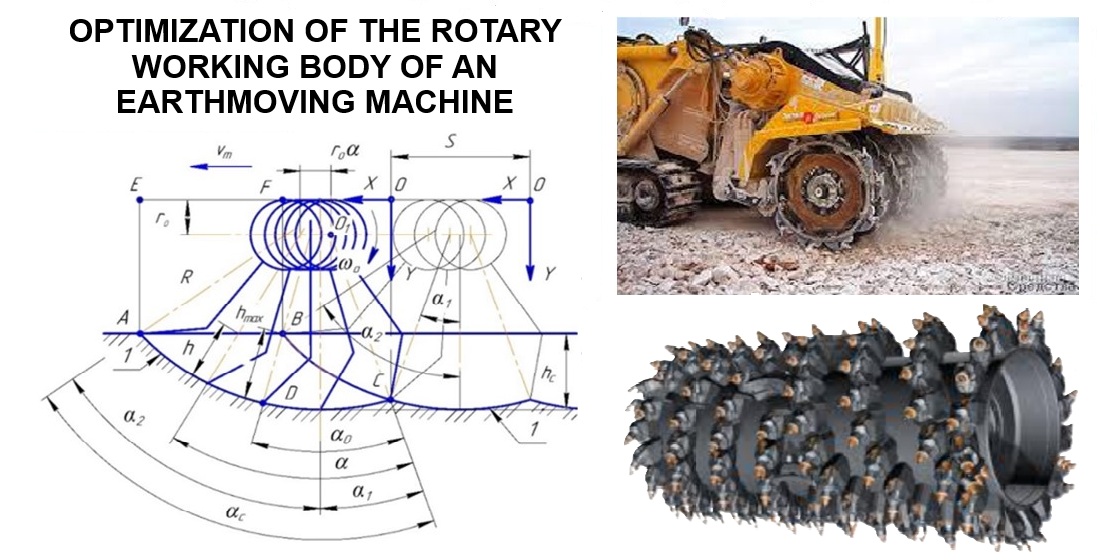

Об’єктом дослідження є робочий процес швидкісного відділення елементів ґрунтового масиву ріжучими елементами ротора. Існуюча проблема полягає в тому, що різання ґрунту ротором відбувається під час поступального руху базової машини. Це створює складну траєкторію ріжучої крайки та призводить до постійної зміни товщини стружки. Врахування траєкторії руху ріжучих крайок і функції зміни товщини стружки дозволяє точніше оцінювати енергетичні характеристики приводу ротора.

Ключові параметри, такі як крутний момент на приводному валу, потужність приводу та споживання енергії, аналізувалися в роботі як функції геометрії робочого органу, частоти обертання, швидкості базової машини та властивостей ґрунту. Отримані математичні моделі враховують фактичні траєкторії ріжучих елементів і зміну товщини різання ґрунту. Також враховано умови взаємодії з навколишнім середовищем та фізико-механічні властивості ґрунту. Розроблено методику інженерного розрахунку та оптимізації параметрів роторного робочого органу. Вона враховує конструкцію та розміри ротора, умови взаємодії та навколишнє середовище. Аналіз робочого процесу роторного робочого органу із заданими параметрами та властивостями ґрунту дозволив встановити наступне:

– Витрати потужності на привід та енергоємність процесу при прямому та зворотному різанні ґрунту практично однакові. Розбіжності не перевищують 5 %.

– У зворотному режимі середня горизонтальна складова опору різанню збільшується у 1,15–1,25 рази, порівняно з прямим різанням. Однак вектор сили опору спрямований у бік руху робочого органу, що зменшує потрібне тягове зусилля базової машини.

– Середнє значення вертикальної складової опору різання у зворотному режимі в 2,0–2,5 рази менше, ніж при прямому різанні. Це зменшує зусилля, необхідне для заглиблення робочого органу або зміни глибини розробки ґрунту.

Представлене дослідження буде корисним для машинобудівних підприємств, що займаються проєктуванням та виготовленням землерийно-дорожніх машин, зокрема з активним роторним робочим органом.

Посилання

- Holubchenko, O. I. (2012). Konstruktsii ta zastosuvannia rizalno-metalnykh orhaniv dlia intensyfikatsii robochykh protsesiv zemleryino-transportnykh mashyn. Stroytelstvo. Materyalovedenye. Mashynostroenye. Seryia: Podemno-transportnye, stroytelnye y dorozhnye mashyny y oborudovanye, 66, 296–302. Available at: https://is.gd/44ZOBj

- Holubchenko, O., Khozhylo, M. (2011). Ohliad ta propozytsii konstruktsii aktyvnoho robochoho obladnannia zemleryino-transportnykh mashyn bezperervnoi dii. Visnyk Prydniprovskoi derzhavnoi akademii budivnytstva ta arkhitektury, 6-7, 48–55.

- Shigley, J. E., Mischke, C. R. (1996). Standard Handbook of Machine Design. New York: McGraw-Hill, 712. Available at: https://is.gd/eRD45S

- Holubchenko, O., Khmara, L. (2023). Formation of working equipment of increased efficiency for earthmoving and transport machines. Visnyk Kharkivskoho natsionalnoho avtomobilno-dorozhnoho universytetu, 2 (101), 88–98.

- Vershkov, O. O., Kolomiiets, S. M., Antonova, H. V. (2014). Kinematyka rotornykh robochykh orhaniv z sylovym pidkliuchenniam gruntoobrobnykh mashyn dlia peredposivnoho obrobitku gruntu. Naukovyi visnyk TDAU, Mashyny i zasoby mekhanizatsii silskohospodarskoho vyrobnytstva, 2 (4), 56–64. Available at: http://nbuv.gov.ua/UJRN/nvtdau_2014_4_2_9

- Tumac, D., Balci, C. (2015). Investigations into the cutting characteristics of CCS type disc cutters and the comparison between experimental, theoretical and empirical force estimations. Tunneling and Underground Space Technology, 45, 84–98. https://doi.org/10.1016/j.tust.2014.09.009

- Kajela, D., Lemu, H. G. (2018). Design and modelling of a light duty trencher for local conditions. Advances in Science and Technology Research Journal, 12, 303–311. https://doi.org/10.12913/22998624/85661

- Yurdakul, M. (2015). Effect of cutting parameters on consumed power in industrial granite cutting processes performed with the multi-disc block cutter. International Journal of Rock Mechanics and Mining Sciences, 76, 104–111. https://doi.org/10.1016/j.ijrmms.2015.03.008

- Kovalychen, Y. (2015). Analytical model of oscillatory disc cutting. International Journal of Rock Mechanics and Mining Sciences, 77, 378–383. https://doi.org/10.1016/j.ijrmms.2015.04.015

- Dixon, P., Crockett, J., Jepson, J. (2012). Performance comparison of diamond-enhanced and tungsten carbide teeth for road milling. Transportation Research Record, 2282, 45–48. https://doi.org/10.3141/2282-05

- Furmanov, D., Chizhov, V., Tyuremnov, I., Troshin, D. (2019). Loads on cutter teeth for removing asphalt pavement. XXII International Scientific Conference: Construction the Formation of Living Environment (FORM-2019). https://doi.org/10.1051/e3sconf/20199706031

- Selech, J., Majchrzycki, W., Ulbrich, D. (2023). Field and laboratory wear tests of machine components used for renovation of dirt roads – A case study. Materials, 16. https://doi.org/10.3390/ma16186180

- Yang, W., Xiao, X., Pan, R., Guo, S., Yang, J. (2023). Numerical simulation of spiral cutter–soil interaction in deep vertical rotary tillage. Agriculture, 13. https://doi.org/10.3390/agriculture13091850

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Oleksandr Holubchenko, Serhii Karpushyn, Roman Krol, Volodymyr Panteleenko, Andrii Chervonoshtan

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.