Determination of rational conditions for the movement of transport and technological units when using technological machines with driving wheels

DOI:

https://doi.org/10.15587/2706-5448.2025.329741Keywords:

transport and technological unit, driving wheels, variable mass, dynamics, vibrations, engine loadAbstract

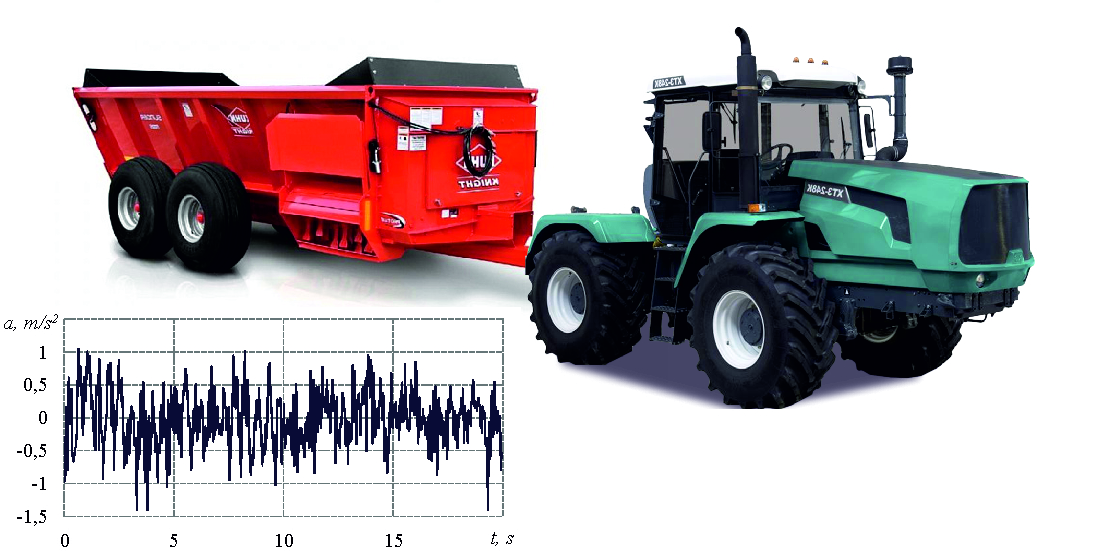

The object of research is the operation process of a transport and technological unit with the driving wheels of a technological machine.

One of the most problematic areas of the effective operation of an energy-intensive tractor as part of a transport and technological unit is the incomplete use of the potential capabilities of the tractor engine. This is due to the fact that at the beginning and at the end of the technological operation the mass of the load of the technological machine will be different. A possible solution to this problem is the use of additional driving axles of the technological machine, which allows to increase the relative share of the coupling weight in the unit. This allows part of the engine power to be realized through the tractor's running system, and part to be transferred to the technological machine.

During the study, it was found that when transferring part of the power to the technological machine, three modes of movement are possible: РkT > Pxm; РkT = Pxm; РkT < Pxm. For their analysis, taking into account the dynamic components of the movement, an equivalent dynamic model of the transport and technological unit was used. The oscillations of longitudinal forces acting on the unit characteristic of each mode of movement were obtained. It was found that the movement of the unit with the transmission of part of the power to the drive wheels of the technological machine must be implemented under the movement condition РkT > Pxm, i. e. under partial underload. This is due to the fact that the proposed movement mode allows stabilizing the oscillations of longitudinal forces and increasing the part of the engine power that can be realized in the traction mode. In particular, for this movement condition, the potential traction force Рka increases to 45.92 kN with a decrease in the mean square deviation σka = 1.74 kN. Also, this movement mode is characterized by the absence of the technological machine running into the tractor, as a result, there are the smallest dynamic oscillations and a stabilizing effect for longitudinal forces.

Due to this, the possibility of activating the wheels of the technological machine with compensation for the negative factors inherent in the movement of all-wheel drive vehicles is ensured. Compared with similar known methods of using full engine power for transport and technological units with variable mass, ensuring a certain movement condition will increase the efficiency of their work.

References

- Darshana, U., Gunathilaka, W., Amadoru, I., Chamara, N. (2018). Performance Evaluation of a Four Wheel Tractor with Different Trailer Loads and Tillage Implements. Proceedings of 17th Agricultural Research Symposium, 232–236. Available at: https://www.researchgate.net/publication/329963372.

- Kalchenko, B. I. (2022). Dynamika rukhu kolisnykh traktoriv. Kharkiv: NTU “KhPI”, 320.

- Shuliak, M. L., Lebedev, A. T., Raputa, V. V., Murchych, M. M. (2025). Energy saving of transport-technological units of variable mass when performing technological operations in crop production. Bulletin of Sumy National Agrarian University. The Series: Mechanization and Automation of Production Processes, 4 (58), 81–88. https://doi.org/10.32782/msnau.2024.4.12

- Rackham, D. H., Blight, D. P. (1985). Four-wheel drive tractors – A review. Journal of Agricultural Engineering Research, 31 (3), 185–201. https://doi.org/10.1016/0021-8634(85)90087-3

- Besselink, B. C. (2003). Tractive efficiency of four-wheel-drive vehicles: An analysis for non-uniform traction conditions. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 217 (5), 363–374. https://doi.org/10.1243/095440703321645070

- Senatore, C., Sandu, C. (2011). Torque distribution influence on tractive efficiency and mobility of off-road wheeled vehicles. Journal of Terramechanics, 48 (5), 372–383. https://doi.org/10.1016/j.jterra.2011.06.008

- Padureanu, V., Lupu, M. I., Canja, C. M. (2013). Theoretical research to improve traction performance of wheeled tractors by using a suplementary driven axle. Computational Mechanics and Virtual Engineering, 410–415.

- Stoilov, S., Kostadinov, G. D. (2009). Effect of weight distribution on the slip efficiency of a four-wheel-drive skidder. Biosystems Engineering, 104 (4), 486–492. https://doi.org/10.1016/j.biosystemseng.2009.08.011

- Shafaei, S. M., Loghavi, M., Kamgar, S. (2020). Ascertainment of driving lead of tractor front wheels as loaded by draft force. Measurement, 165, 108134. https://doi.org/10.1016/j.measurement.2020.108134

- Shafaei, S. M., Loghavi, M., Kamgar, S. (2018). An extensive validation of computer simulation frameworks for neural prognostication of tractor tractive efficiency. Computers and Electronics in Agriculture, 155, 283–297. https://doi.org/10.1016/j.compag.2018.10.027

- Bulgakov, V., Ivanovs, S., Adamchuk, V., Antoshchenkov, R. (2019). Investigations of the Dynamics of a Four-Element Machine-and-Tractor Aggregate. Acta Technologica Agriculturae, 22 (4), 146–151. https://doi.org/10.2478/ata-2019-0026

- Antoshchenkov, R., Halych, I., Nykyforov, А., Cherevatenko, H., Chyzhykov, I., Sushko, S. et al. (2022). Determining the influence of geometric parameters of the traction-transportation vehicle’s frame on its tractive capacity and energy indicators. Eastern-European Journal of Enterprise Technologies, 2 (7 (116)), 60–67. https://doi.org/10.15587/1729-4061.2022.254688

- Kozhushko, A., Pelypenko, Y., Kravchenko, S., Danylenko, V. (2023). Improving the procedure for modeling low-frequency oscillations of the free surface liquid in a tractor tank. Eastern-European Journal of Enterprise Technologies, 2 (7 (122)), 61–68. https://doi.org/10.15587/1729-4061.2023.277254

- Kozhushko, A.; Cioboată, D. D. (Eds.) (2023). Hydrodynamics Analysis on Partially Filled Agricultural Tanks by Driving Cycle of Transportation. International Conference on Reliable Systems Engineering (ICoRSE), ICoRSE 2023. Lecture Notes in Networks and Systems, 762. Cham: Springer, 253–262. https://doi.org/10.1007/978-3-031-40628-7_21

- Preda, I. (2005). Aspects Regarding the Wheel Loads of Tractor-Semitrailer Road Train. CAR 2005 International Automotive Congress At: Pitesti, Romania, 1114. Available at: https://www.researchgate.net/publication/263238490

- Alipour, K., Robat, A. B., Tarvirdizadeh, B. (2019). Dynamics modeling and sliding mode control of tractor-trailer wheeled mobile robots subject to wheels slip. Mechanism and Machine Theory, 138, 16–37. https://doi.org/10.1016/j.mechmachtheory.2019.03.038

- Ha, D. V., Tan, V. V., Niem, V. T., Sename, O. (2022). Evaluation of Dynamic Load Reduction for a Tractor Semi-Trailer Using the Air Suspension System at all Axles of the Semi-Trailer. Actuators, 11 (1), 12. https://doi.org/10.3390/act11010012

- Chaplinskyi, A., Nadykto, V. (2024). Research of the plowing quality with a unit based on a modular traction-transportation vehicle. E3S Web of Conferences, 508, 08002. https://doi.org/10.1051/e3sconf/202450808002

- Churakova, E. Y. (2023). Rational Design of Wheel Systems of Multi-Axle Heavy Trucks Taking into Account the Stressed State of Pavement. Transportation Research Procedia, 68, 739–749. https://doi.org/10.1016/j.trpro.2023.02.102

- Antoshchenkov, R., Cherevatenko, G., Zadorozhny, V., Svitlichny, O., Kuskov, M. (2023). Research of the dynamics of the all-wheel-drive tractor-transport machine. Ukrainian Journal of Applied Economics and Technology, 8 (3), 336–341. https://doi.org/10.36887/2415-8453-2023-3-51

- Karelina, M., Rakov, V., Ershov, V., Klimenko, V. (2021). A hybrid drive system for off-roaders with a powered trailer to be used in the Arctic Region. Transportation Research Procedia, 57, 285–290. https://doi.org/10.1016/j.trpro.2021.09.053

- Rebrov, O., Kozhushko, A., Kalchenko, B., Mamontov, A., Zakovorotniy, A., Kalinin, E., Holovina, E. (2020). Mathematical model of diesel engine characteristics for determining the performance of traction dynamics of wheel-type tractor. EUREKA: Physics and Engineering, 4, 90–100. https://doi.org/10.21303/2461-4262.2020.001352

- Lebedev, A., Shuliak, M., Lebedev, S., Khalin, S., Haidai, T., Kholodov, A. et al. (2024). Determining conditions for providing maximum traction efficiency of tractor as part of a soil tillage unit. Eastern-European Journal of Enterprise Technologies, 1 (1 (127)), 6–14. https://doi.org/10.15587/1729-4061.2024.297902

- Podryhalo, M. A., Artomov, M. P. (2025). Metod partsialnykh pryskoren ta yoho zastosuvannia v dynamitsi mobilnykh mashyn. Kharkiv: Vyd-vo “Estet Print”, 232.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Mykhailo Shuliak, Andrii Chepizhnyi, Tetiana Khvorost, Serhii Sokolik, Maksym Murchych

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.