Математичні та графічні підходи удосконалення в циркуляційній системі бурової установки процесу насичення промивальної рідини повітрям

DOI:

https://doi.org/10.15587/2706-5448.2025.329744Ключові слова:

циркуляційна система, блок очистки, конструкція, піногенератор, математичне моделювання, програмне середовище, графічні дослідженняАнотація

Об’єктом дослідження є процес насичення промивальної рідини повітрям із використанням багатосоплового піногенератора у циркуляційних системах бурових установок.

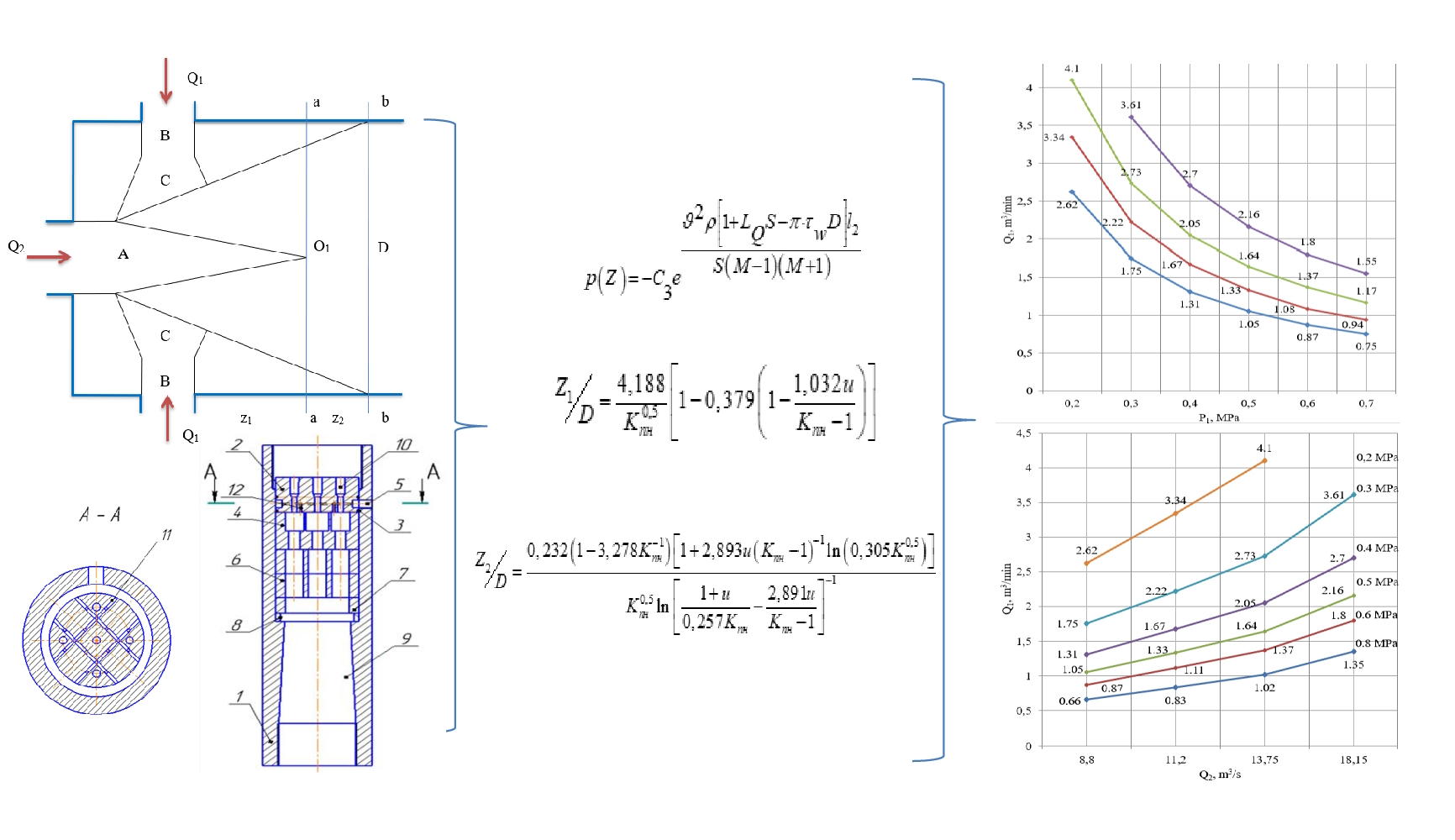

Одним з найбільш проблемних місць у відомих конструкціях піногенераторів є недостатня ефективність насичення рідини повітрям, яка вирішується за допомогою запропонованої в роботі конструкції. Запропонована конструкція багатосоплового піногенератора шляхом удосконалення камери змішування. Дана конструкція дозволила забезпечити покращене піноутворення, ефективніше насичення промивальної рідини повітрям, скорочення часу освоєння свердловин та підвищення продуктивності пристрою без зміни тиску та подачі рідини та повітря.

В ході дослідження використовувалися комп’ютерні математичні моделювання (в програмному середовищі Maple 9.5), виконувалося дослідження залежностей витрати повітря від тиску та витрати рідини при діаметрах сопла 4 мм і 6 мм. В дослідженнях розглянуто графічний аналіз для визначення оптимальних режимів роботи піногенератора.

Отримано удосконалений багатосопловий піногенератор з покращеною ефективністю піноутворення, рівномірним насиченням промивальної рідини повітрям, зменшеними енергетичними витратами та скороченим часом освоєння свердловин. Це пов'язано з удосконаленням конструкції камери змішування, що має ряд особливостей. Запропонована конструкція забезпечує інтенсивну турбулентність, рівномірне змішування рідини з повітрям, оптимізацію геометричних параметрів сопел і каналів подачі, а також зменшення гідравлічних втрат у процесі піноутворення.

Завдяки цьому дослідженню забезпечується можливість отримання показників, що характеризують закономірність нарощення витрати повітря пропорційно до зростання тиску. У порівнянні з відомими аналогами, запропонований піногенератор, завдяки змінним геометричним параметрам камери змішування та сопел, дозволяє отримувати пінні суміші з ширшим спектром властивостей. Такі геометричні зміни забезпечують краще насичення рідини повітрям, створюють більш інтенсивну турбулентність, знижують гідравлічні втрати, а також підвищують продуктивність і ефективність освоєння свердловин.

Посилання

- Savyk, V. M., Liakh, M. M., Mykhailiuk, V. V. (2013). Pat. No. 77955 UA. Pinoheneruiuchyi prystrii bahatosoplovyi. MPK V01F 3/04, E02V 8/00. No. u201205435; declareted: 03.05.12; published: 11.03.13. Bul. No. 5, 6.

- Liakh, M. M., Savyk, V. M., Molchanov, P. O. (2017). Experimental and industrial research on foamgenerating devices. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, 5 (161), 17–23. Available at: https://nvngu.in.ua/index.php/uk/arkhiv-zhurnalu/za-vipuskami/1493-2017-ukr/zmist-5-2017/rozrobka-rodovishch-korisnikh-kopalin/4151-eksperimentalni-ta-promislovi-doslidzhennya-pinogeneruyuchikh-pristrojiv

- Kuzmenko, V. P., Lysenko, O. M. (2012). Otsinka vplyvu heometrychnykh parametriv na robotu pinoheneruiuchoho prystroiu. Rozvidka ta rozrobka naftovykh i hazovykh rodovyshch, 2 (43), 123–130. Available at: https://irbis-nbuv.gov.ua/cgi-bin/irbis_nbuv/cgiirbis_64.exe?C21COM=2&I21DBN=UJRN&IMAGE_FILE_DOWNLOAD=1&Image_file_name=PDF%2Frrngr_2012_2_23.pdf&P21DBN=UJRN

- Petrenko, I. V., Sydorenko, R. M. (2016). Improving the efficiency of foamgenerating devices of pump-circulative systems of drilling sets. Naukovyi visnyk NHU, 3, 56–63. Available at: https://mail.nvngu.in.ua/index.php/uk/arkhiv-zhurnalu/za-vipuskami/1247-2016/zmist-3-2016/rozrobka-rodovishch-korisnikh-kopalin/3517-pidvishchennya-efektivnosti-pinogeneruyuchikh-pristrojiv-nasosno-tsirkulyatsijnikh-sistem-burovikh-ustanovok

- Cao, P., Chen, Z., Liu, M., Cao, H., Chen, B. (2019). Numerical and experimental study of a novel aerodynamic foam breaker for foam drilling fluid. Energy Science & Engineering, 7 (6), 2410–2420. https://doi.org/10.1002/ese3.428

- Shendrik, O., Fyk, M., Biletskyi, V., Kryvulia, S., Donskyi, D., Alajmeen, A., Pokhylko, A. (2019). Energy-saving intensification of gas-condensate field production in the east of Ukraine using foaming reagents. Mining of Mineral Deposits, 13 (2), 82–90. https://doi.org/10.33271/mining13.02.082

- Liakh, M. M., Savyk, V. M., Molchanov, P. O. (2016). Improving the efficiency of foam-generating devices of pump-circulative systems of drilling sets. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, 3, 16–23. Available at: https://nvngu.in.ua/index.php/uk/arkhiv-zhurnalu/za-vipuskami/1247-2016/zmist-3-2016/rozrobka-rodovishch-korisnikh-kopalin/3517-pidvishchennya-efektivnosti-pinogeneruyuchikh-pristrojiv-nasosno-tsirkulyatsijnikh-sistem-burovikh-ustanovok

- Krot, O. Yu., Korobko, B. O., Krot, O. P., Virchenko, V. V. (2023). Eksperymentalni metody doslidzhen. Poltava: NUPP, 192.

- Syvko, V. Ya., Skubok, Ye. O. (1998). Rukh dynamichnoi systemy z urakhuvanniam vnutrishnoho oporu seredovyshcha. Zbirnyk naukovykh prats “Vibrotekhnolohiia – 98”. Obrobka dyspersnykh materialiv i seredovyshch. Teoriia, doslidzhennia. Tekhnolohiia ta obladnannia. Kyiv: NVO “VOTUM”, 16–21.

- Kaliuzhnyi, A., Molchanov, P., Savyk, V., Knysh, M., Yaremiychuk, R. (2022). Determining foaming regularities enabled by a five-nozzle foam generator for drilling technologies under conditions of abnormally low pressures. Eastern-European Journal of Enterprise Technologies, 4 (1 (118)), 72–79. https://doi.org/10.15587/1729-4061.2022.262506

- Lu, C., Wu, Y., Zhu, D., Liang, Y. (2024). Study on the foam production characteristics of air self-suction foam generator by jet. https://doi.org/10.21203/rs.3.rs-4804887/v1

- Li, D., Li, F., Deng, S., Liu, J., Huang, Y., Yang, S. (2022). Preparation of Oil-Based Foam Gel with Nano-SiO2 as Foam Stabilizer and Evaluation of Its Performance as a Plugging Agent for Fractured Shale. Geofluids, 2022, 1–12. https://doi.org/10.1155/2022/9539999

- Al-Darweesh, J., Aljawad, M. S., Al-Ramadan, M., Elkatatny, S., Mahmoud, M., Patil, S. (2022). Review of underbalanced drilling techniques highlighting the advancement of foamed drilling fluids. Journal of Petroleum Exploration and Production Technology, 13 (4), 929–958. https://doi.org/10.1007/s13202-022-01596-w

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Petro Molchanov, Tetiana Surzhko, Maksym Knysh, Yuliya Sribna, Vasyl Savyk, Serhii Novopysmennyi, Oleksii Debre, Yuliia Salenko, Serhii Hudz, Dmytro Zakomirnyi

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.