Розробка аналітичної моделі контрольованого руху зернового матеріалу по пересипним полицям завантажувальної гравітаційно-каскадної установки

DOI:

https://doi.org/10.15587/2706-5448.2025.330574Ключові слова:

швидкість руху зерна, розгінні та гальмівні полиці, змінні кути нахилуАнотація

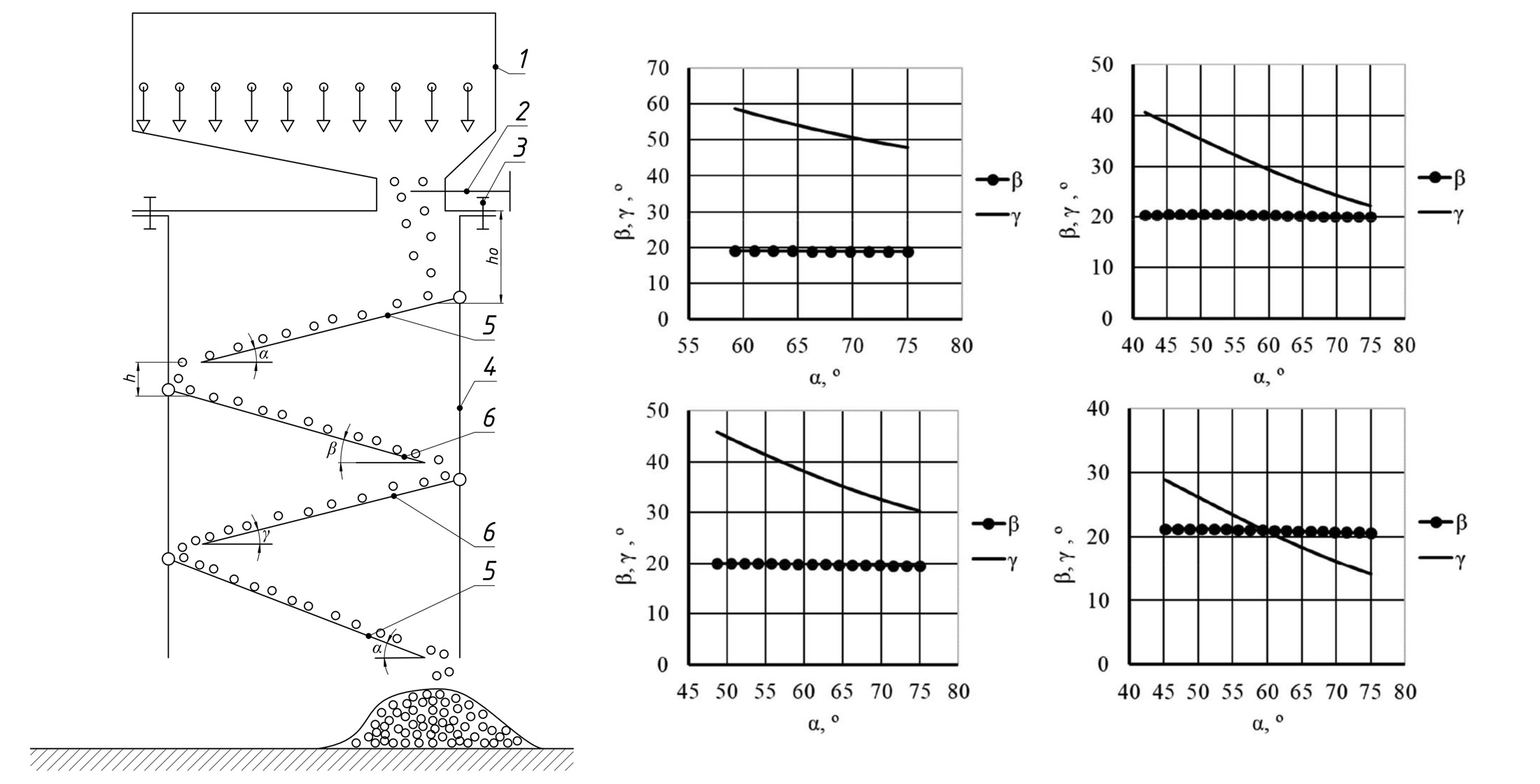

Об’єктом дослідження є гравітаційний рух зерна по пересипним полицям та каскадній завантажувальній установці з двома розгінними та двома гальмівними ділянками. Дослідження такого руху здійснюється для підтвердження теоретичних досліджень, щодо розробки та обґрунтування аналітичної моделі контрольованого гравітаційного руху зерна по пересипним полицям.

При завантаженні зерна воно, падаючи зі значної висоти та ударяючись об дно та стінки ємності, може травмуватися. Зазначена проблема потребує розробки та дослідження технічного рішення, яке б забезпечувало регулювання швидкості руху зерна при його завантаженні у ємності.

Теоретичні дослідження проводилися із застосуванням розробленої аналітичної моделі руху зерна та запропонованих рівнянь для знаходження співвідношень між кутами нахилу розгінних та гальмівних полиць гравітаційно-каскадної установки. На основі аналітичної моделі була виготовлена експериментальна установка із двох розгінних і двох гальмівних полиць. Полиці можуть вільно повертатись на осях на необхідний кут в межах від 0° до 90° відносно горизонтальної площини. Для полиць розгінних ділянок кут нахилу α вибирався з варіативного ряду 45°, 50°, 60°. Орієнтуючись на кут α, згідно моделі полиця першої гальмівної ділянки встановлювалась під кутом 20,43°, 20,48°, 20,32°, а полиця другої гальмівної ділянки – 38,46°, 35,28°, 29,32°.

Експериментальні дослідження показали, що швидкість руху зерна дійсно регулюється комбінацією співвідношень кутів розгінних та гальмівних полиць. При цьому швидкість зерна на останній гальмівній ділянці є близькою до початкової швидкості потоку на початку першої розгінної полиці. Значення абсолютних та відносних похибок дослідів експериментально визначених швидкостей та теоретичного значення швидкості засвідчують цілком допустимі межі відхилень для даного багатофакторного експерименту. Відносне відхилення експериментальної від теоретичної швидкості руху зернової маси не перевищує 12,76%.

Отримані результати та їх аналіз свідчать про те, що представлена аналітична модель та спроектована гравітаційно-каскадна установка за рахунок гальмівних і розгінних ділянок дозволяє вирішити проблему контрольованого руху швидкості зерна для його завантаження у ємності без травмування, зокрема у силосні споруди.

Посилання

- Derev’ianko, D., Sukmaniuk, O., Sarana, V., Derev’ianko, O. (2020). Justification of influence of the working bodies of combine harvesters on damage and quality of seed. Visnyk Agrarnoi Nauky, 98 (2), 64–71. https://doi.org/10.31073/agrovisnyk202002-10

- Nurmagambetov, A., Kurmanov, A., Ryspayev, K., Bekmyrza, Z., Keklis, A. (2024). Analysis of Grain Damage by the Bucket Elevator during Loading/Unloading. Communications – Scientific Letters of the University of Zilina, 26 (1), B54–B62. https://doi.org/10.26552/com.c.2024.013

- Chen, Z., Wassgren, C., Ambrose, K. (2020). A Review of Grain Kernel Damage: Mechanisms, Modeling, and Testing Procedures. Transactions of the ASABE, 63 (2), 455–475. https://doi.org/10.13031/trans.13643

- Derev’ianko, D. A., Melnik, V. І., Derev’ianko, O. D. (2015). Influence workspace bucket carrier injury and quality cereal seeds. Tekhnіka, energetika, transport APK, 3 (92), 73–78.

- Zeng, C., Wang, Y. (2019). Compressive behaviour of wheat from confined uniaxial compression tests. International Agrophysics, 33 (3), 347–354. https://doi.org/10.31545/intagr/110809

- Gao, M., Cheng, X., Hu, M., Du, X. (2019). Simulation of static stress distribution of wheat piles in silos by the modified Cam-clay model. International Agrophysics, 33 (1), 11–19. https://doi.org/10.31545/intagr/103749

- Tverdokhlib, I. V. (2017). Dynamics of particle movement in cutting grain environment. Vibratsiia v tekhnitsi ta tekhnolohiiakh, 3 (86), 128–135.

- Antonets, A. V., Flegantov, L. O., Ivanov, O. M., Arendarenko, V. M., Koshova, O. P. (2021). Investigating controlled grain gravitational movement in sloping channel with three variable angles. Bulletin of Poltava State Agrarian Academy, 3, 265–273. https://doi.org/10.31210/visnyk2021.03.33

- Arendarenko, V., Antonets, A., Ivanov, O., Dudnikov, I., Samoylenko, T. (2021). Building an analytical model of the gravitational grain movement in an open screw channel with variable inclination angles. Eastern-European Journal of Enterprise Technologies, 3 (7 (111)), 100–112. https://doi.org/10.15587/1729-4061.2021.235451

- Pylypaka, S., Nesvidomin, V., Zaharova, T., Pavlenko, O., Klendiy, M. (2019). The Investigation of Particle Movement on a Helical Surface. Advances in Design, Simulation and Manufacturing II, 671–681. https://doi.org/10.1007/978-3-030-22365-6_67

- Arendarenko, V., Samoilenko, Т., Ivanov, О., Ryzhkova, Т. (2023). Results of experimental research on the distribution of a falling grain from a toro-shaped plate on a flat surface. Scientific Progress & Innovations, 26 (1), 96–101. https://doi.org/10.31210/spi2023.26.01.15

- Melnyk, V. I., Samoilenko, T. V. (2018). Analysis of directions for improving the design of devices for loading silos. Engineering of nature management, 1 (9), 83–90.

- Narendran, R. B., Jian, F., Jayas, D. S., Fields, P. G., White, N. D. G. (2019). Segregation of canola, kidney bean, and soybean in wheat bulks during bin loading. Powder Technology, 344, 307–313. https://doi.org/10.1016/j.powtec.2018.12.042

- Han, Y., Li, D., Chen, J., Jing, H., Duan, J. (2018). Experimental study on boundary pressure and wall friction under static grain storage in silo. Transactions of the Chinese Society of Agricultural Engineering, 34 (13), 296–302. https://doi.org/10.11975/j.issn.1002-6819.2018.13.036

- Abdelbarr, M. H., Ramadan, O. M. O., Hilal, A., Sanad, A. M., Abdalla, H. A. (2024). Retracted Article: Current design of rectangular steel silos: limitations and improvement. Journal of Engineering and Applied Science, 71 (1). https://doi.org/10.1186/s44147-024-00401-1

- Samojlenko, T. V., Arendarenko, V. N., Melnik, V. I. (2019). Theoretical simulation of the process of gravitational loading of a silo with grain through an open screw channel. Engineering of nature management, 2 (12), 73–78.

- Morozov, I. V., Dudin, O. V. (2003). Model of grain trajectory on the surfaces of agricultural machines. Bulletin of Kharkiv State Technical University of Agriculture “Mechanization of Agricultural Production”, 21, 124–131.

- Gevko, B. M. (2012). Mathematical model of grain movement on moving surfaces of sowing machines. Collection of scientific works of Vinnytsia National Agrarian University. Technical Sciences, 11 (1), 113–118.

- Omarov, A., Müller, P., Tomas, J. (2013). Influence of Loading Rate on the Deformation and Fracture Behavior of Wheat Grains. Chemie Ingenieur Technik, 85 (6), 907–913. https://doi.org/10.1002/cite.201200054

- Fan, J., Wang, H., Luu, L.-H., Philippe, P., Wang, L., Wei, Z., Yu, J. (2023). Numerical study of granular discharge flows through centred and off-centred rectangular hoppers using discrete element simulations. Powder Technology, 429, 118964. https://doi.org/10.1016/j.powtec.2023.118964

- Naumenko, M. M., Sokol, S. P., Filipenko, D. V., Guridova, V. O. (2017). Mathematical model of grain mixture motion in a cylindrical sieve rotating around an axis. Geotechnical Mechanics, 133, 250–256.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Anatolii Antonets, Volodymyr Arendarenko, Oleg Ivanov, Ihor Dudnikov, Serhii Liashenko

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.