Вплив властивостей зливків вторинного α-титану, отриманих безкамерною електрошлаковою виплавкою, на оброблюваність точінням

DOI:

https://doi.org/10.15587/2706-5448.2025.331902Ключові слова:

зливок, оброблюваність, α-титан, шорсткість, міцність, макростуктура, мікроструктура, точіння, зносостійкість, твердістьАнотація

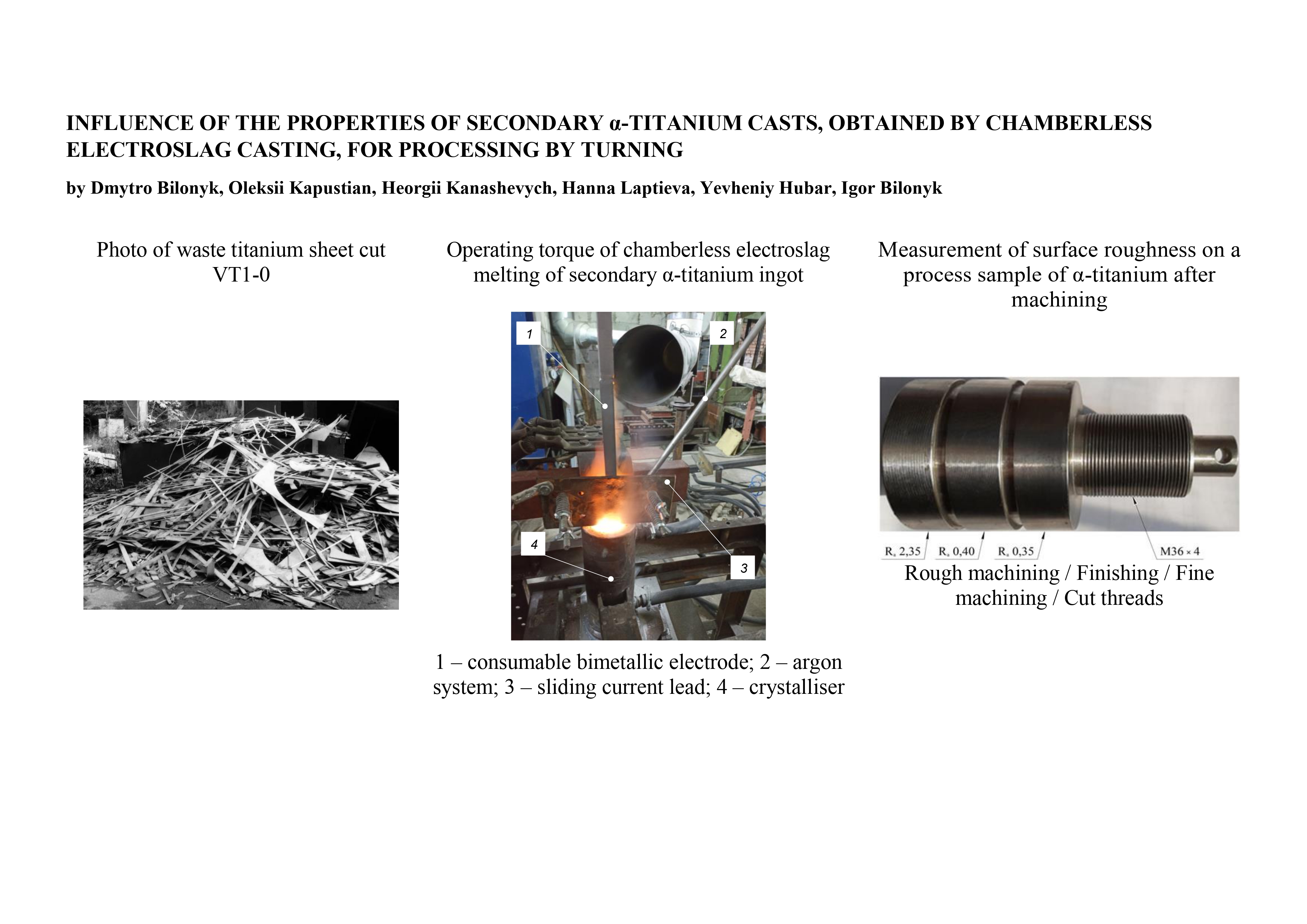

Об’єктом досліджень є здатність до оброблюваності точінням зливків вторинного α-титану, отриманих за технологією безкамерної електрошлакової виплавки (далі – вторинний α-титан) з залученням до виготовлення витратних електродів 100% відходів листової обрізі титану ВТ1-0. Одним з найбільш проблемних місць є важкість механічної обробки титану та вторинного титану. Зокрема, це налипання стружки на інструмент обробки, що обумовлене високою пластичністю титанових сплавів, а також підвищення температури на контактних поверхнях, що призводить до окислювання.

В ході дослідження використовувалися сучасні металографічні методи для вивчення макроструктури, хімічного складу та механічних властивостей α-титану, експериментальні методи підбору раціональних режимів точіння, метод графічної інтерполяції для визначення коефіцієнту оброблюваності. Оцінювання зносостійкості різців проводилося методом порівняння.

Встановлено оптимальні параметри режиму для видалення альфірованого шару, а також для отримання шорсткості поверхні 5–8 класу: швидкість різання V = 25–30 мм⁄хв; подача S = 0,5–0,9 мм⁄об; глибина різання Т = 1,0–1,2 мм. Визначені режими точіння дозволяють отримувати складні різьбові профілі у відповідності до вимог ISO 724:1993. Проведеними дослідженнями доведено, що точіння зливків вторинного α-титану не потребує додаткових технологічних заходів та високо зносостійких спеціальних інструментів. При цьому, коефіцієнт оброблюваності складає 0,47–0,48. Покращена оброблюваність зливків вторинного α-титану пояснюється його високою якістю, забезпеченою крапельним перенесенням металу та послідовною кристалізацією зливків у водоохолоджувальному мідному кристалізаторі, що призводить до підвищення рівня щільності та однорідності структурного стану. Застосування безкамерної електрошлакової технології виплавки забезпечило покращення якості α-титану та розширило можливості використання даного сплаву для виготовлення деталей машинобудівної, хімічної, авіаційної галузей.

Отримання вторинного α-титану з використанням титанових відходів безкамерною технологією виплавки забезпечує зниження собівартості отримання вторинного α-титану в межах 25–30%.

Посилання

- Sheiko, I. V., Shapovalov, V. A., Konstantinov, V. S. (2007). Alternative technologies of remelting of industrial wastes of titanium and alloys thereof. Sovremennaia elektrometallurgiia, 3 (88), 44–53. Available at: http://dspace.nbuv.gov.ua/handle/123456789/95819

- Kolobov, G. A., Vodennikov, S. A., Pecheritca, K. A., Lichkonenko, N. V., Bubinetc, A. V. (2017). Technologies of utilization of circulating castings wastes are in productions of titanic shaped casting and bars. Metallurgiia, 2 (38), 46–60. Available at: https://dspace.znu.edu.ua/jspui/handle/12345/466

- Tebaldo, V., Gautier di Confiengo, G., Duraccio, D., Faga, M. G. (2023). Sustainable Recovery of Titanium Alloy: From Waste to Feedstock for Additive Manufacturing. Sustainability, 16 (1), 330. https://doi.org/10.3390/su16010330

- Burnashev, V. R., Nykytenko, Yu. O., Barabash, V. V., Shapovalov, V. O. (2021). Remelting wastes of titanium and titanium alloys under the conditions of plasma-arc melting. Suchasna Elektrometallurgiya, 4, 32–37. https://doi.org/10.37434/sem2021.04.05

- Mazur, M. P., Vnukov, Yu. M., Hrabchenko, A. I., Dobroskok, V. L., Zaloha, V. O., Novosolov, Yu. K., Yakubov, F. Ya. (2020). Osnovy teorii rizannia materialiv. Lviv: Novyi Svit – 2000, 471.

- Kiianovskyi, M. V., Tsyvinda, N. I., Pikilniak, A. V., Zuiev, I. O. (2024). Zalezhnosti protsesu rizannia vazhkoobrobliuvanykh materialiv detalei hirnycho-metalurhiinoho kompleksu yak vypadkovi funktsii. Rozvytok promyslovosti ta suspilstva. Kryvyi Rih, 169. Available at: http://ds.knu.edu.ua/jspui/handle/123456789/7090

- Che-Haron, C. H. (2001). Tool life and surface integrity in turning titanium alloy. Journal of Materials Processing Technology, 118 (1-3), 231–237. https://doi.org/10.1016/s0924-0136(01)00926-8

- Niknam, S. A., Khettabi, R., Songmene, V. (2014). Machinability and Machining of Titanium Alloys: A Review. Machining of Titanium Alloys, 1–30. https://doi.org/10.1007/978-3-662-43902-9_1

- Bilanenko, V. H. (2019). Physical and technological features of titanium alloy machining. ΛΌГOΣ. The art of scientific mind, 2, 90–93.

- Seredenko, B. M., Zabolotnii, O. A., Orobchenko, A. P. (2016). Determination of cutting temperature while milling titanium alloy by face mills. Journal of Mechanical Engineering the National Technical University of Ukraine “Kyiv Polytechnic Institute”, 3 (78), 71–75. https://doi.org/10.20535/2305-9001.2016.78.84954

- Mazur, M. P., Vnukov, Yu. M., Hrabchenko, A. I., Dobroskok, V. L., Zaloha, V. O., Novosolov, Yu. K., Yakubov, F. Ya. (2021). Osnovy teorii rizannia materialiv. Vydannia 2-e pereroblene i dopovnene. Lviv: Novyi Svit – 2000, 428.

- Bulyha, Yu. V., Veselovska, N. R., Miskov, V. P. (2019). Teoriia rizannia. Rozrakhunok rezhymiv rizannia. Vinnytsia: VNTU, 67.

- Palyvoda, Yu. Ye., Diachun, A. Ye., Leshchuk, R. Ya. (2019). Instrumentalni materialy, rezhymy rizannia, tekhnichne normuvannia mekhanichnoi obrobky. Ternopil: Ternopilskyi natsionalnyi tekhnichnyi universytet imeni Ivana Puliuia, 240.

- Bilonik, D. I., Ovchynnykov, О. V., Bilonik, I. M., Kapustian, O. Ye., Shumikin, S. A., Raspornia, D. V., Savonov, Yu. M. (2022). Electroslag melting in an open mould of ingots from sheet scrap wastes of titanium VT1-0. Suchasna Elektrometallurgiya, 1, 34–39. https://doi.org/10.37434/sem2022.01.04

- Mishchenko, A. V. (2019). Status and trends of development of the production of cold-rolled tubes from titanium alloys. Metall i lite Ukrainy, 3-4, 58–68. Available at: http://nbuv.gov.ua/UJRN/MLU_2019_3-4_10

- Koike, M., Jacobson, D., S. Chan, K., Okabe, T. (2009). Grindability of alpha-case formed on cast titanium. Dental Materials Journal, 28 (5), 587–594. https://doi.org/10.4012/dmj.28.587

- Mishchenko, V. G., Menyaylo, A. I. (2015). Control of carburization and decarburization processes of alloy steels at thermo-chemical and thermal treatment. Metallurgical and Mining Industry, 11, 244–249.

- Netrebko, V. V., Volchok, I. P., Popov, S. M., Akimov, I. V. (2022). Specific Features of the Fracture of High-Chromium Cast Irons Under Abrasive Wear. Materials Science, 57 (4), 439–445. https://doi.org/10.1007/s11003-022-00563-4

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Dmytro Bilonyk, Oleksii Kapustian, Heorgii Kanashevych, Hanna Laptieva, Yevheniy Hubar, Igor Bilonyk

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.