Оцінка деформаційних процесів у закладальних масивах на моделях з подрібненої породи

DOI:

https://doi.org/10.15587/2706-5448.2025.333869Ключові слова:

закладальний масив, деформація, ущільнення, подрібнена порода, конвергенція, безпечні умови праціАнотація

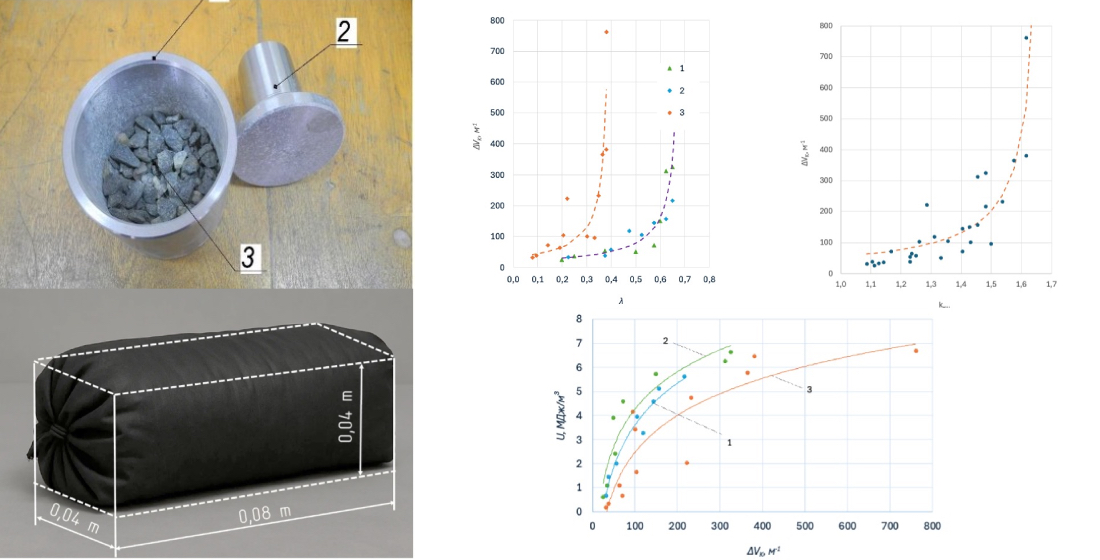

Об’єктом дослідження були деформаційні процеси у закладальних масивах з подрібненої породи, які застосовуються для управління покрівлею на виїмкових ділянках. Досліджувалась проблема запобігання обвалень бічних порід за рахунок забезпечення тримкості закладальних масивів. Деформаційні процеси досліджувались на експериментальних моделях з подрібненої породи, які імітували різні закладальні масиви. Розглядалось одновісне стиснення подрібненої породи з можливістю її бічного розширення та компресійне стиснення. Одновісне стиснення застосовувалось для моделювання часткового, а компресійне стиснення – повного закладання виробленого простору. В умовах навантаження закладальних масивів встановлено гіперболічну залежність між відносною змінною об’єму закладального матеріалу на одиницю конвергенції бічних порід ΔVK (м–1) та коефіцієнтом ущільнення подрібненої породи, яка дозволяє спрогнозувати граничну усадку матеріалу. Визначальним фактором встановленої залежності є відносна деформація закладального масиву. При навантаженні подрібненої породи та порівнюваних величинах коефіцієнту її ущільнення, різниця у деформаційних характеристиках досягає 2,5–3 разів. Вона фіксується за рахунок трансформації форми або зміни об’єму у різних умовах стиснення. Показано, що зі зростанням параметру ΔVK

питома потенціальна енергія деформації закладального матеріалу змінюється за логарифмічною залежністю. Густина енергії обумовлюється механічними характеристиками та умовами стиснення подрібненої породи.

Максимальну стійкість підготовчих виробок, підтримуваних позаду очисного вибою здатне забезпечити застосування повної закладки виробленого простору, при чому очікувана усадка закладального масиву залежить від початкової щільності закладання та деформаційних характеристик подрібненої породи, що використовується для закладки.

Посилання

- Feng, X., Zhang, N., Gong, L., Xue, F., Zheng, X. (2015). Application of a Backfilling Method in Coal Mining to Realise an Ecologically Sensitive “Black Gold” Industry. Energies, 8 (5), 3628–3639. https://doi.org/10.3390/en8053628

- Jiang, H., Cao, Y., Huang, P., Fang, K., Li, B. (2015). Characterisation of coal-mine waste in solid backfill mining in China. Mining Technology, 124 (1), 56–63. https://doi.org/10.1179/1743286315y.0000000002

- Yıldız, T. D. (2020). Waste management costs (WMC) of mining companies in Turkey: Can waste recovery help meeting these costs? Resources Policy, 68, 101706. https://doi.org/10.1016/j.resourpol.2020.101706

- Bachurin, L. L., Iordanov, I. V., Simonova, Yu. I., Korol, A. V., Podkopaiev, Ye. S., Kayun, O. P. (2020). Experimental studies of the deformation characteristics of filling massifs. Technical Engineering, 2 (86), 136–149. https://doi.org/10.26642/ten-2020-2(86)-136-149

- KD 12.01.01.503-2001. Upravlenie krovlei i kreplenie v ochistnykh zaboiakh na ugolnykh plastakh s uglom padeniia do 35°(2002). Kyiv: Mintopenergo Ukrainy, DonUGI, 141.

- Jing, Y., Xu, Y., Bai, J., Li, Y., Li, J. (2025). Mechanism and Control Technology of Lateral Load-Bearing Behavior of a Support System Adjacent to Empty Roadways. Applied Sciences, 15 (3), 1200. https://doi.org/10.3390/app15031200

- Podkopaiev, S., Gogo, V., Yefremov, I., Kipko, O., Iordanov, I., Simonova, Y. (2019). Phenomena of stability of the coal seam roof with a yielding support. Mining of Mineral Deposits, 13 (4), 28–41. https://doi.org/10.33271/mining13.04.028

- Krupnik, L. A., Shaposhnik, Yu. N., Shaposhnik, S. N., Tursunbaeva, A. K. (2013). Backfilling technology in Kazakhstan mines. Journal of Mining Science, 49 (1), 82–89. https://doi.org/10.1134/s1062739149010103

- Zhukov, V. E., Vystorop, V. V., Kolchin, A. M., Grigoriuk, E. V. (1984). Malootkhodnaia tekhnologiia dobychi uglia. Kyiv: Tekhnika, 144.

- Malashkevych, D. S. (2021). Rozrobka tekhnolohichnykh skhem selektyvnoho vidpratsiuvannia plastiv iz zalyshenniam porody u vyroblenomu prostori (na prykladi shakht Zakhidnoho Donbasu). Dnipro: LizunovPres, 189.

- Shashenko, O. M., Maikherchyk, T., Sdvyzhkova, O. O. (2005). Heomekhanichni protsesy u porodnykh masyvakh. Dnipropetrovsk: Natsionalnyi hirnychyi universytet, 319.

- Kline, S. J. (1986). Similitude and Approximation Theory. Springer Berlin Heidelberg, 229. https://doi.org/10.1007/978-3-642-61638-9

- Shashenko, O. M., Pustovoitenko, V. P., Sdvyzhkova, O. O. (2016). Heomekhanika. Kyiv: Novyi druk, 528.

- Pappas, D. M., Mark, C. (1993). Behavior of simulated longwall gob material (Report of Investigations No. 9458). U.S. Bureau of Mines.

- Sadd, M. H. (2009). Elasticity. Elsevier. https://doi.org/10.1016/B978-0-12-374446-3.X0001-6

- Chepiga, D., Polii, D., Podkopaiev, S., Bachurin, L., Bielikov, A., Slashchov, I. et al. (2025). Evaluating the stiffness of a cast strip for protecting a preparatory mine working. Eastern-European Journal of Enterprise Technologies, 2 (1 (134)), 40–50. https://doi.org/10.15587/1729-4061.2025.324548

- Petlovanyi, M., Malashkevych, D., Sai, K., Bulat, I., Popovych, V. (2021). Granulometric composition research of mine rocks as a material for backfilling the mined-out area in coal mines. Mining of Mineral Deposits, 15 (4), 122–129. https://doi.org/10.33271/mining15.04.122

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Oleksandr Tkachuk, Daria Chepiga, Leonid Bachurin, Serhii Podkopaiev, Yaroslava Bachurina, Yevgen Podkopayev, Mykola Rudynets, Olena Visyn

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.