Optimization of the composition of aluminum phosphate and walnut shell-based composition to increase the corrosion resistance of paint coatings

DOI:

https://doi.org/10.15587/2706-5448.2025.334800Keywords:

aluminum phosphate, walnut shell, pigment, corrosion, mathematical model of corrosion rateAbstract

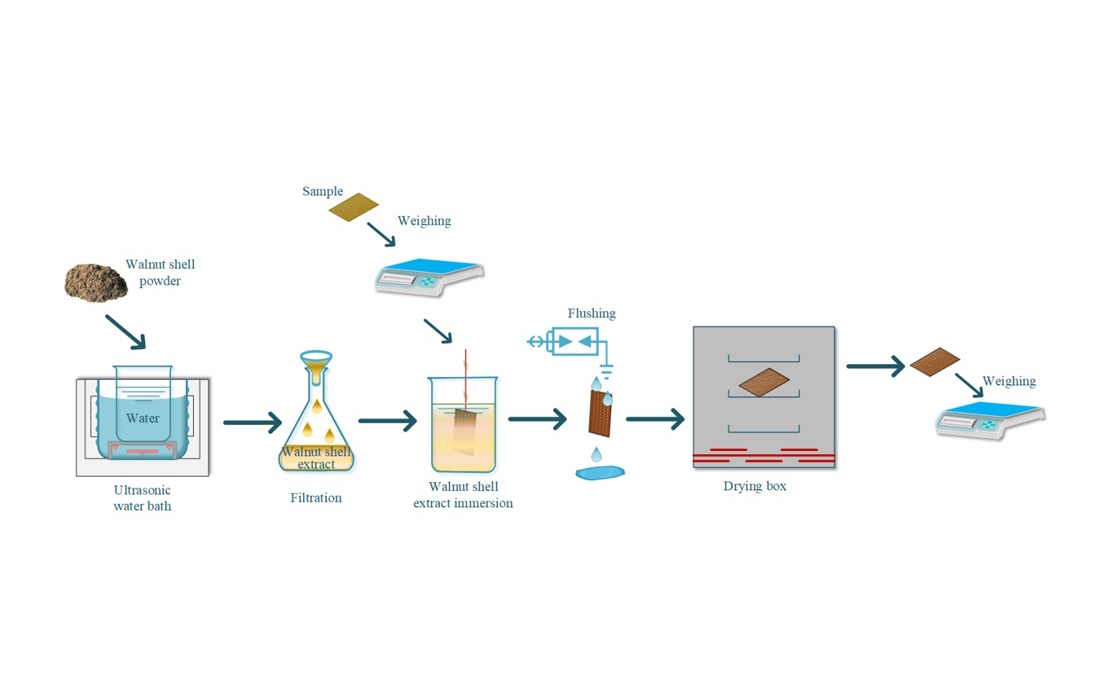

The object of the study is аnti-corrosion properties of walnut shell powder and aluminum phosphate mixtures. The existing problem is that the most effective chromate-containing pigments, which were traditionally used for the manufacture of paint and varnish coatings, are toxic. Given this fact, the research of scientists aims at finding alternative low-toxic compounds, which are phosphate pigments. Since they are inferior in efficiency, modern research is aimed either at the synthesis of new modifications and complex forms of pigments, or at the development of effective mixtures of pigments that would provide the necessary level of anti-corrosion protection of steel. Along with this, an urgent direction is to increase the level of environmental friendliness of paint and varnish coatings using annually renewable plant waste, which, due to the content of tannins, have proven themselves well for surface preparation before painting. The work investigated the effect of a mixture of non-toxic aluminum phosphate and finely ground walnut shell powder on the corrosion behavior of steel. An adequate mathematical model “composition – mass corrosion index” was proposed. The mathematical model allowed to establish the relationship between the composition and corrosion rate and find the optimal composition of the studied mixture. The calculations showed that at a ratio of aluminum phosphate and walnut shell powder of about 8:1, the mass corrosion rate of steel in the obtained extract is 0.020 g / (m2 · h). By experimentally verifying the optimal composition of the study, a mass corrosion index of 0.018 g / (m2 · h) was achieved, which confirms the theoretical calculations and ensures the practical applicability of the results obtained.

The results of the study will be useful for specialists working in the field of developing water-based anti-corrosion paints and coatings, with an emphasis on studying the influence of pigments and fillers on the corrosion behavior of steel.

References

- Sinko, J. (2001). Challenges of chromate inhibitor pigments replacement in organic coatings. Progress in Organic Coatings, 42 (3-4), 267–282. https://doi.org/10.1016/s0300-9440(01)00202-8

- Jašková, V., Kalendová, A. (2012). Anticorrosive coatings containing modified phosphates. Progress in Organic Coatings, 75 (4), 328–334. https://doi.org/10.1016/j.porgcoat.2012.07.019

- Kowalczyk, K., Łuczka, K., Grzmil, B., Spychaj, T. (2012). Anticorrosive polyurethane paints with nano- and microsized phosphates. Progress in Organic Coatings, 74 (1), 151–157. https://doi.org/10.1016/j.porgcoat.2011.12.003

- Ahmed, N. M., Mohamed, H. A. (2011). Performance of phosphate–alumina pigments in waterborne paints for protection of cold-rolled steel. Journal of Coatings Technology and Research, 8 (2), 201–210. https://doi.org/10.1007/s11998-010-9288-8

- Naderi, R., Arman, S. Y., Fouladvand, Sh. (2014). Investigation on the inhibition synergism of new generations of phosphate-based anticorrosion pigments. Dyes and Pigments, 105, 23–33. https://doi.org/10.1016/j.dyepig.2014.01.015

- Ramezanpour, J., Ramezanzadeh, B., Samani, N. A. (2024). Progress in bio-based anti-corrosion coatings; A concise overview of the advancements, constraints, and advantages. Progress in Organic Coatings, 194, 108556. https://doi.org/10.1016/j.porgcoat.2024.108556

- Sienkiewicz, N., Dominic, M., Parameswaranpillai, J. (2022). Natural Fillers as Potential Modifying Agents for Epoxy Composition: A Review. Polymers, 14 (2), 265. https://doi.org/10.3390/polym14020265

- Nnaji, N., Mbah, P. C., Ebenso, E. E. (2023). The role of vegetal tannins in metal corrosion inhibition vis-à-vis agricultural wastes. Smart Anticorrosive Materials, 401–420. https://doi.org/10.1016/b978-0-323-95158-6.00014-x

- Queirós, C. S. G. P., Cardoso, S., Lourenço, A., Ferreira, J., Miranda, I., Lourenço, M. J. V. et al. (2020). Characterization of walnut, almond, and pine nut shells regarding chemical composition and extract composition. Biomass Conversion and Biorefinery, 10 (1), 175–188. https://doi.org/10.1007/s13399-019-00424-2

- Haddadi, S. A., Kohlan, T. B., Momeni, S., Ramazani, S. A., A., Mahdavian, M. (2019). Synthesis and application of mesoporous carbon nanospheres containing walnut extract for fabrication of active protective epoxy coatings. Progress in Organic Coatings, 133, 206–219. https://doi.org/10.1016/j.porgcoat.2019.04.046

- Chyhyrynets, O. Е. (2023). Influence of ultrasonic treatment of combined mixtures based on walnut shell and titanium dioxide on their extractiveness. Scientific Notes of Taurida National V. I. Vernadsky University. Series: Technical Sciences, 34 (2 (73)), 67–71. https://doi.org/10.32782/2663-5941/2023.2.2/12

- GB/T 700-2006: Carbon structural steels (2006). Available at: https://www.antpedia.com/standard/5124518-1.html Last accessed: 25.02.2025

- Salleh, S. Z., Yusoff, A. H., Zakaria, S. K., Taib, M. A. A., Abu Seman, A., Masri, M. N. et al. (2021). Plant extracts as green corrosion inhibitor for ferrous metal alloys: A review. Journal of Cleaner Production, 304, 127030. https://doi.org/10.1016/j.jclepro.2021.127030

- Bondarenko, S. H., Sanhinova, O. V., Shakhnovskyi, A. M. (2024). Chyselni metody v khimii ta khimichnii tekhnolohii. Kyiv: KPI im. Ihoria Sikorskoho, 564. Available at: https://ela.kpi.ua/handle/123456789/67248

- Sanhinova, O. V., Bondarenko, S. H. (2021). Svidotstvo pro reiestratsiiu avtorskoho prava na tvir No. 105383. Kompiuterna prohrama “OPTIMIZ-M”. Data reiestratsii 09.06.2021. Bul. No. 65. Available at: https://sis.nipo.gov.ua/uk/search/detail/1618634

- Kipton, H., Powell, J., Rate, A. (1987). Aluminum-Tannin Equilibria: A Potentiometric Study. Australian Journal of Chemistry, 40 (12), 2015. https://doi.org/10.1071/ch9872015

- Zhang, L., Liu, R., Gung, B. W., Tindall, S., Gonzalez, J. M., Halvorson, J. J. et al. (2016). Polyphenol-Aluminum Complex Formation: Implications for Aluminum Tolerance in Plants. Journal of Agricultural and Food Chemistry, 64 (15), 3025–3033. https://doi.org/10.1021/acs.jafc.6b00331

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Olena Chyhyrynets, Olga Sanginova, Jinping Hu, Yehui Wu, Xiangrong He

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.