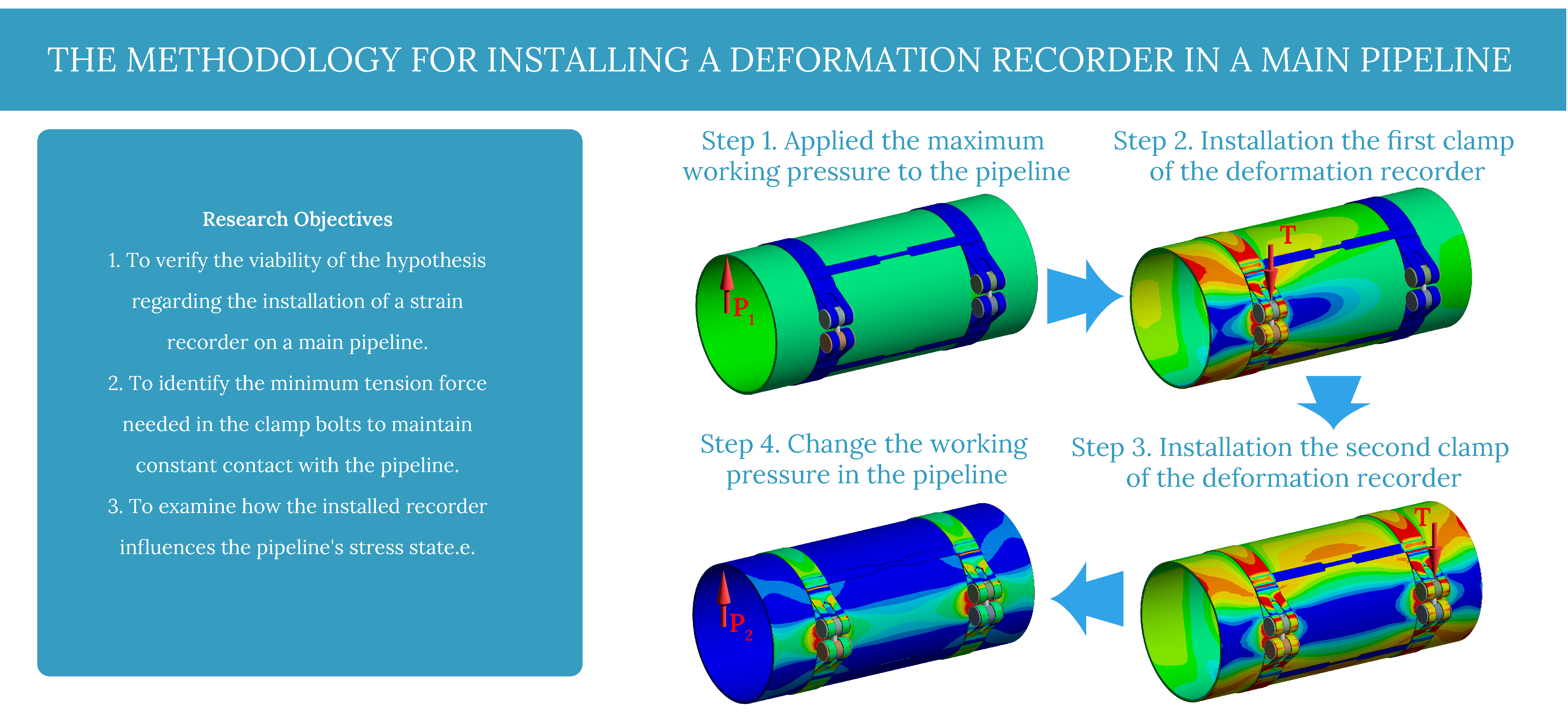

Justification of the methodology for installing a deformation recorder in a main pipeline section through analysis of its stress-strain state

DOI:

https://doi.org/10.15587/2706-5448.2025.336165Keywords:

main oil and gas pipeline, stress-strain state, express analysis, deformation recorderAbstract

Object of the research is a deformation recorder designed for monitoring the stress-strain state of main pipelines. This study investigates the hypothesis regarding the feasibility of installing a deformation recorder on a pipeline section that has been preloaded with the maximum allowable operating pressure, in order to ensure the recorder’s reliable performance under various pipeline operating conditions. Structurally, the examined deformation recorder consists of two clamps, with four longitudinal strain multipliers mounted at diametrically opposite locations between them. By comparing their relative strain values, it is possible to determine the spatial curvature of the pipeline axis. A 3D model of a pipeline section with a diameter of 270 mm and wall thickness of 5 mm was developed, incorporating a deformation recorder with a measurement base of 300 mm. Based on this model, a multi-step finite element model was created to calculate the stress-strain state and the contact interaction of a 4.6-meter-long pipeline section. One end of the pipeline was modeled as axially compliant, and the stress recorder was installed on it. Series of numerical experiments were conducted to analyze the stress-strain behavior of the assembly under varying preload forces of the clamp bolts. The results confirmed the initial hypothesis and allowed the determination of an acceptable preload range. Specifically, the preload force must be no less than 15 kN to ensure secure attachment of the clamps on a non-operational pipeline, and must not exceed 30 kN to comply with the pipeline’s strength requirements. Based on the analysis, recommendations were made regarding the development of a redesigned clamp lock. Additionally, the study proposes that changing the material of the deformation recorder may reduce the required bolt preload force.

References

- Xu, W., Li, H., Song, Z., Meng, C. (2024). An Assessment of the Residual Stress of Pipelines Subjected to Localized Large Deformations. Journal of Marine Science and Engineering, 12 (10), 1789. https://doi.org/10.3390/jmse12101789

- Fan, X., Zhang, L., Wang, J., Ren, Y., Liu, A. (2024). Analysis of faulting destruction and water supply pipeline damage from the first mainshock of the February 6, 2023 Türkiye earthquake doublet. Earthquake Science, 37 (1), 78–90. https://doi.org/10.1016/j.eqs.2023.11.004

- Rybakov, A. A., Garf, E. F., Iakimkin, A. V., Lokhman, I. V., Burak, I. Z. (2015). Otcenka napriazhenno-deformirovannogo sostoianiia uchastka gazoprovoda s mestnoi poterei ustoichivosti. Avtomaticheskaia svarka, 2 (740), 42–49. Available at: https://patonpublishinghouse.com/as/pdf/2015/as201502all.pdf

- Kuzo, I. V., Kunta, O. Ye., Kharchenko, Ye. V. (2016). Rozrakhunok nadzemnoi dilnytsi mahistralnoho truboprovodu na stiikist. Avtomatyzatsiia vyrobnychykh protsesiv u mashynobuduvanni ta pryladobuduvanni, 50, 45–53. Available at: http://nbuv.gov.ua/UJRN/Avtomatyzac_2016_50_8

- Liu, X., Sun, Z., Zhu, J., Fang, Y., He, Y., Pan, Y. (2022). Study on Stress-Strain Characteristics of Pipeline-Soil Interaction under Ground Collapse Condition. Geofluids, 2022, 1–25. https://doi.org/10.1155/2022/5778761

- Kryzhanivsky, Ye. I. (2005). Innovations in Securing a Reliable Exploitation of Pipe-Lines in Hazardous Landslide Mountainous Areas. Science and Innovation, 1 (5), 101–106. https://doi.org/10.15407/scin1.05.101

- Bastun, V. M., Bespalova, O. I., Urusova, H. P., Minakov, S. M. (2014). Pat. No. 87458 UA. Method for monitoring of technical state of main pipelines. MKP F17D1/00, G01L1/00. No. u201309614; declareted: 01.08.2013; published: 10.02.2014, Bul. No. 3/2014. Available at: https://sis.nipo.gov.ua/uk/search/detail/1104768/

- Yavorskyi, A. V., Aifa Takhar, Raiter, P. M., Rybitskyi, I. V., Vashchyshak, S. P. (2012). Metodychne i tekhnichne zabezpechennia poperedzhennia heodynamichnoi nebezpeky v zoni proliahannia naftohazoprovodiv. Rozvidka ta rozrobka naftovykh i hazovykh rodovyshch, 4 (45). Available at: https://pdogf.com.ua/uk/journals/4-45

- Lyskanych, M. V., Dzhus, A. P., Shlapak, L. S., Slabyi, O. O., Kostiv, V. V., Penkivskyi, V. Yu. (2021). Pat. No. 145986 UA. Sposib monitorynhu tekhnichnoho stanu dilianok mahistralnykh truboprovodiv. MKP G01L1/18, G01N3/06. No. u202004717; declareted: 24.07.2020; published: 13.01.2021, Bul. No. 2/2021. Available at: https://sis.nipo.gov.ua/uk/search/detail/1472510/

- Lyskanych, M. V., Dzhus, A. P., Shlapak, L. S., Slabyi, O. O., Kostiv, V. V., Penkivskyi, V. Yu. (2021). Pat. No. 150013 UA. Stend testuvannia i taruvannia prystroiu reiestratsii deformatsii. MKP G01N3/10; G01N3/20; G01M13/027. No. u202104310; declareted: 23.07.2021; published: 22.12.2021, Bul. No. 51/2021. Available at: https://sis.nipo.gov.ua/uk/search/detail/1669800/

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Орест Олегович Слабий, Любомир Степанович Шлапак, Ярослав Степанович Гриджук, Руслан Олександрович Дейнега, Василь Ярославович Попович

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.