Improving the design of the extruder to improve the quality of polymer products

DOI:

https://doi.org/10.15587/2706-5448.2025.336199Keywords:

extruder, extrusion, worm, turns, three-section compression zone, barrier gap, reducing polymer degradation, melt uniformity, quality improvementAbstract

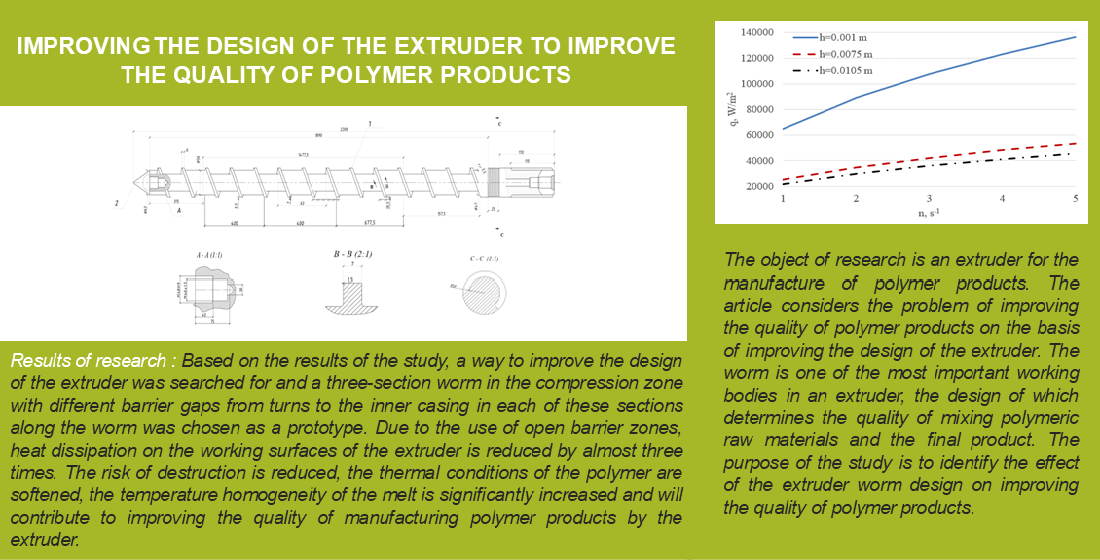

The object of research is an extruder for the manufacture of polymer products. The article considers the problem of improving the quality of polymer products on the basis of improving the design of the extruder. The selected design of the extruder with the execution of a three-section worm in the compression zone with different heights of barrier gaps in each section. The ratio of the length of individual sections to the total length of the compression zone should be in the range of 0.1–0.5. In this case, the height of the barrier gap in the first section should exceed the height of the gaps in subsequent sections by 1.1 times between adjacent turns of the worm. In the first section with a larger gap, there is an intensive dissipation of the mechanical energy of the drive, which leads to the melting of the polymer and the release of heat. At the same time, a significant part of the unmolten material is retained before entering subsequent sections with a smaller gap. Thus, the worm does not experience a sharp increase in pressure in the compression zone and local overheating of the material along its length in the compression section. In subsequent sections, further separation of the melt and solid particles of the polymer occurs, and the clearance height decreases gradually, ensuring a controlled distribution of heat flows in the material. The proposed design of a worm in the compression zone with a closed barrier gap h = 0.001 m and open barrier gaps h at 0.0105 m and 0.0075 m is illustrated by the example of an extruder (D = 0.63 m; φ = 17.1°) in the processing of recycled high-pressure polyethylene. The use of open barrier gaps between the worm and the extruder body reduces heat dissipation on its working surfaces by almost three times than with closed barrier gaps, as demonstrated by the obtained dependence of the dissipation function on the worm rotation speed. This reduces the risk of material degradation, the thermal conditions of the polymer stay are mitigated, the homogeneity of the melt increases and will contribute to improving the quality of finished polymer products, in particular polymer pipes, films, etc.

References

- Ekstruziia: tekhnolohiia i ustatkuvannia dlia pererobky polimeriv. TEN24. Available at: https://ten24.com.ua/ua/blog/ekstruziya-tekhnologiya-i-oborudovanie-dlya-pererabotki-polimerov/

- Mikulonok, I. O., Sokolskyi, O. L., Sivetskyi, V. I., Radchenko, L. B. (2015). Osnovy proektuvannia odnocherviachnykh ekstruderiv. Kyiv: NTUU “KPI”, 200. Available at: https://core.ac.uk/download/pdf/323528341.pdf

- Mikulonok, I. O., Havva, O. M., Kryvoplias-Volodina, L. O. (2022). Innovatsiine obladnannia dlia pryhotuvannia ta pereroblennia polimernykh materialiv i humovykh sumishei. Kyiv: Natsionalnyi universytet kharchovykh tekhnolohii, 139. Available at: https://ela.kpi.ua/server/api/core/bitstreams/5bc425b0-a57f-4cbc-9cba-6283ca0736ef/content

- Mikulonok, I. O., Vynohradov, Ye. Yu. (2010). Pat. No. 47082 UA. Worm of extruder. MPK B29C 47/60, B30B 11/22. No. u200909282; declareted: 09.09.2009; published: 11.01.2010, Bul. No. 1, 2. Available at: https://sis.nipo.gov.ua/uk/search/detail/263123/

- Joachim, S. (2011). Рat. PL 209296 B1. Wytłaczarka ślimakowa. No. 381315/209396B1, Int.CI. B29C 4T/60 (2006.01), B29C 4T/38 (2006.01). published: 31.08.2011, 4. Available at: https://worldwide.espacenet.com/patent/search/family/043035555/publication/PL209296B1?q=pn%3DPL209296B1

- Sokolskyi, O. L., Mikulonok, I. O., Ivitskyi, I. I. (2015). Pat. 102908 UA. Extruder worm. MPK B29C 47/60. No. u201504969; declareted: 21.05.2015; published: 25.11.2015, Bul. No. 22, 3. Available at: https://sis.nipo.gov.ua/uk/search/detail/853092/

- Mikulonok, I. O., Bardashevskyi, S. V., Horpyniuk, V. Yu. (2017). Pat. No. 119024 UA. Cherviachnyi ekstruder. MPK B29C 47/36 (2006.01), B30B 9/14 (2006.01). No. u2017 01975; declareted: 01.03.2017; published: 11.09.2017, Bul. No. 1, 3. Available at: https://sis.nipo.gov.ua/uk/search/detail/758856/

- Mikulonok, I. O., Lukiniuk, M. V. (2021). Pat. No. 146329 UA. Cherviak ekstrudera. MPK B29C 48/84 (2019.01). No. U202006311; declareted: 29.09.2020; published: 10.02.2021, Bul. No. 6, 3. Available at: https://sis.nipo.gov.ua/uk/search/detail/1476181/

- Chao, T., Hua, L. (2021). Рat. No. CN 113246438 A, No. CN 202110762829.5A, IntCl. B29D 7/01(2006.01). Single-screw extruder for processing liquid crystal polymer and film forming method. Published: 13.08.2021, 10. Available at: https://patents.google.com/patent/CN113246438A/en?oq=%E2%84%96+CN+113246438+A%2c+%E2%84%96+CN+202110762829.5A

- Jochen, H. (2007). Europäische patentschrift. No. EP 1854613 B1, No. DE 102006022123, IntCl. B29C 47/60 (2006.01). Schneckenpresse sowie Förder und Mischverfahren für die Verarbeitung thermoplastischer und nicht vernetzender Polymere, Veröffentlicht 14.11.2007, 8. Available at: https://patentimages.storage.googleapis.com/0a/0e/33/e1144348fe779e/EP1854613B1.pdf

- Jiang, Z., Yang, Y., Mo, S., Yao, K., Gao, F. (2012). Polymer Extrusion: From Control System Design to Product Quality. Industrial & Engineering Chemistry Research, 51 (45), 14759–14770. https://doi.org/10.1021/ie301036c

- Deng, J., Li, K., Harkin-Jones, E., Price, M., Karnachi, N., Kelly, A. et al. (2014). Energy monitoring and quality control of a single screw extruder. Applied Energy, 113, 1775–1785. https://doi.org/10.1016/j.apenergy.2013.08.084

- Mikulonok, I. O. (2009). Obladnannia i protsesy pererobky termoplastychnykh materialiv z vykorystanniam vtorynnoi syrovyny. Kyiv: IVTs “Vydavnytstvo “Politekhnika”, 265. Available at: https://cpsm.kpi.ua/Doc/Mono_MIO-2009.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Iryna Kazak, Dmitry Sidorov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.