Assessing the risks of applying artificial intelligence to occupational safety

DOI:

https://doi.org/10.15587/2706-5448.2025.339322Keywords:

artificial intelligence, occupational safety, risk management, ethics, legal responsibility, automationAbstract

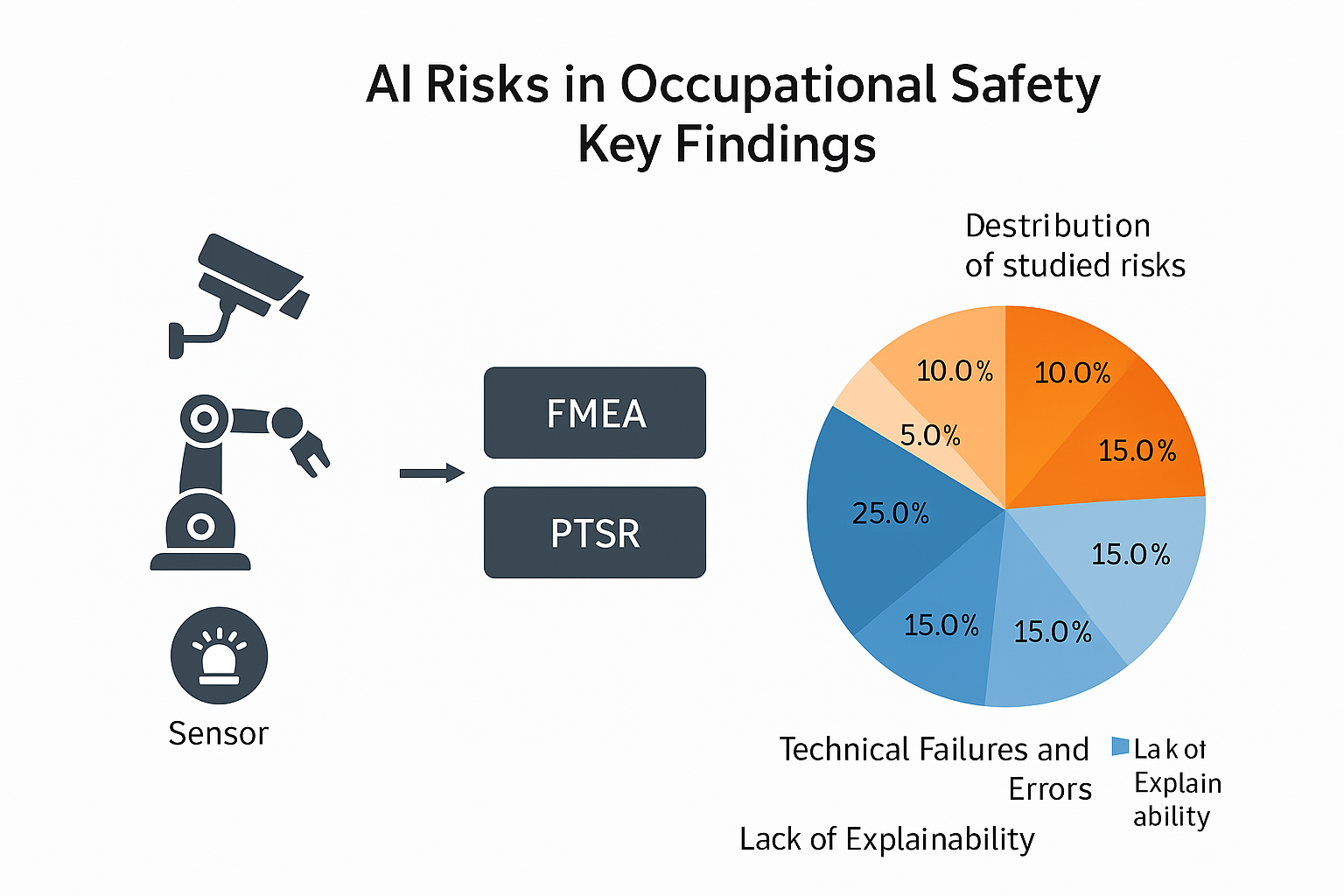

This paper explores the opportunities, advantages, and risks of integrating artificial intelligence (AI) into occupational health and safety management systems. It is noted that the use of intelligent technologies contributes to improved workplace safety by enabling automatic monitoring of working conditions, detection and prediction of hazardous situations, and real-time analysis of workers’ behavior. The potential of AI is demonstrated in identifying safety violations, monitoring the use of personal protective equipment, responding to dangerous events, and organizing preventive actions. Special attention is given to technical, legal, ethical, and organizational risks associated with AI implementation in industrial settings. The study analyzes risks related to AI-based systems in occupational safety using the example of a food processing plant with an automated packaging line. An incident involving worker injury due to the AI system’s failure to detect human presence in the manipulator zone is examined. The application of the FMEA method identified key risk sources: failure to detect a person in the hazardous zone (RPN = 270), lack of integration between AI and emergency stop systems (RPN = 192), and loss of communication between modules (RPN = 140). All risks exceeded the RPN > 100 threshold, indicating high priority. The relevance of a multisensor approach, implementation of fail-safe protocols, and redesigning human–machine interaction architecture is substantiated. A comparison is made between the FMEA (failure modes

and effects analysis) method and the PTSR (Probability – Time – Severity Risk), which incorporates the time factor of hazard exposure, increasing risk assessment accuracy in dynamic environments. A combined risk management approach is proposed, integrating preventive analysis (FMEA) and real-time operational evaluation (PTSR), which enhances safety control effectiveness when using adaptive AI systems.

References

- Falsk, R. (2023). AI for Predictive Maintenance in Industrial Systems. Handbuch Ansehen. https://doi.org/10.13140/RG.2.2.27313.35688

- Xu, S., Wang, J., Shou, W., Ngo, T., Sadick, A.-M., Wang, X. (2020). Computer Vision Techniques in Construction: A Critical Review. Archives of Computational Methods in Engineering, 28 (5), 3383–3397. https://doi.org/10.1007/s11831-020-09504-3

- Chen, K., Wang, C., Chen, L., Niu, X., Zhang, Y., Wan, J. (2020). Smart safety early warning system of coal mine production based on WSNs. Safety Science, 124, 104609. https://doi.org/10.1016/j.ssci.2020.104609

- Cebulla, A., Szpak, Z., Howell, C., Knight, G., Hussain, S. (2022). Applying ethics to AI in the workplace: the design of a scorecard for Australian workplace health and safety. AI & SOCIETY, 38 (2), 919–935. https://doi.org/10.1007/s00146-022-01460-9

- Fernández Peñalver, M. (2024). The Foundations of AI Safety: Ensuring Technical Robustness. Nemko. Available at: https://www.nemko.com/blog/ai-safety-and-robustness

- Alateeq, M. M., Rajeena, F. P. P., Ali, M. A. S. (2023). Construction Site Hazards Identification Using Deep Learning and Computer Vision. Sustainability, 15 (3), 2358. https://doi.org/10.3390/su15032358

- Nagda, P. (2025). Legal Liability and Accountability in AI Decision-Making: Challenges and Solutions. International Journal of Innovative Research in Technology, 11 (11). Available at: https://ijirt.org/publishedpaper/IJIRT174899_PAPER.pdf

- Čartolovni, A., Tomičić, A., Lazić Mosler, E. (2022). Ethical, legal, and social considerations of AI-based medical decision-support tools: A scoping review. International Journal of Medical Informatics, 161, 104738. https://doi.org/10.1016/j.ijmedinf.2022.104738

- Fernández, J. (2024). Integrating AI into Functional Safety Management. Safe and Explainable. Critical Embedded Systems based on AI. Available at: https://safexplain.eu/integrating-ai-into-functional-safety-management/

- Berezutskyi, P. S., Horbenko, S. V. (2017). Otsenka rycka ot KhPY. Okhrana truda, 11, 14–16. Available at: https://www.researchgate.net/publication/394486032_Formiruem_risk-orientirovannoe_myslenie

- Mahdavinejad, M. S., Rezvan, M., Barekatain, M., Adibi, P., Barnaghi, P., Sheth, A. P. (2018). Machine learning for internet of things data analysis: a survey. Digital Communications and Networks, 4 (3), 161–175. https://doi.org/10.1016/j.dcan.2017.10.002

- AI in worker management: involving people to prevent risks (2025). ENSHPO. Available at: https://www.enshpo.eu/ai-in-worker-management-involving-people-to-prevent-risks/

- Lialiuk, O., Osypenko, R. (2023). Features of the implementation of artificial intelligence in construction. Modern Technology, Materials and Design in Construction, 35 (2), 172–176. https://doi.org/10.31649/2311-1429-2023-2-172-176

- Implementing safer AI worker management through policy and prevention (2024). European Agency for Safety and Health at Work (EU-OSHA). Available at: https://osha.europa.eu/en/oshnews/implementing-safer-ai-worker-management-through-policy-and-prevention

- Chauhan, S., Vashishtha, G., Zimroz, R. (2024). Analysing Recent Breakthroughs in Fault Diagnosis through Sensor: A Comprehensive Overview. Computer Modeling in Engineering & Sciences, 141 (3), 1983–2020. https://doi.org/10.32604/cmes.2024.055633

- ISO 21448:2022. Road vehicles – Safety of the intended functionality (2022). ISO. Available at: https://www.iso.org/standard/77490.html

- Ryan, P., Porter, Z., Al-Qaddoumi, J., McDermid, J., Habli, I. (2023). What's my role? Modelling responsibility for AI-based safety-critical systems. arXiv:2401.09459. https://doi.org/10.48550/arXiv.2401.09459

- AI Risk Management Framework (AI RMF 1.0) (2023). NIST. Available at: https://www.nist.gov/itl/ai-risk-management-framework

- Gunning, D. (2017). XAI: Explainable Artificial Intelligence. DARPA. Available at: https://www.darpa.mil/program/explainable-artificial-intelligence

- Epelboim, M. (2025). Cursor Rules: Why Your AI Agent Is Ignoring You (and How to Fix It). Available at: https://sdrmike.medium.com/cursor-rules-why-your-ai-agent-is-ignoring-you-and-how-to-fix-it-5b4d2ac0b1b0

- ISO/IEC TR 24028:2020. Information technology – Artificial intelligence Overview of trustworthiness in artificial intelligence (2020). ISO. Available at: https://www.iso.org/standard/77608.html

- Recommendation of the Council on Artificial Intelligence (2019). Paris: OECD Publishing. Available at: https://legalinstruments.oecd.org/en/instruments/OECD-LEGAL-0449

- Kusche, I. (2024). Possible harms of artificial intelligence and the EU AI act: fundamental rights and risk. Journal of Risk Research, 1–14. https://doi.org/10.1080/13669877.2024.2350720

- An Occupational Safety and Health Perspective on Human in Control and AI (2022). BauA. Available at: https://www.baua.de/EN/Service/Publications/Essays/article3454

- Huibregtse, A. (2025). AI provides innovative ways to improve compliance with labour laws. ILO. Available at: https://www.ilo.org/resource/article/ai-provides-innovative-ways-improve-compliance-labour-laws

- Volkswagen robot kills worker in Germany (2015). The Guardian. Available at: https://www.theguardian.com/world/2015/jul/02/robot-kills-worker-at-volkswagen-plant-in-germany

- Yang, X., Li, Y., Chen, Y., Li, Y., Dai, L., Feng, R., Duh, Y.-S. (2020). Case study on the catastrophic explosion of a chemical plant for production of m-phenylenediamine. Journal of Loss Prevention in the Process Industries, 67, 104232. https://doi.org/10.1016/j.jlp.2020.104232

- Tim, B., Zoë, D., Gerald, P. (2019). Mineworker fatigue: A review of what we know and future decisions. Minerals Engineering, 70 (3), 33. Available at: https://pmc.ncbi.nlm.nih.gov/articles/PMC5983045/

- Reports of Fatalities and Catastrophes – Archive. OSHA. Available at: https://www.osha.gov/fatalities/reports/archive

- Travmatyzm. Statystyka. Prychyny. Derzhavna sluzhba Ukrainy z pytan pratsi. Available at: https://dsp.gov.ua/category/diyalnist/travmatyzm-statystyka-prychyny/

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Viacheslav Berezutskyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.