Formation and properties of NbC-reinforced layers obtained by electroslag surfacing in a small-diameter current-fed crystallizer

DOI:

https://doi.org/10.15587/2706-5448.2025.341827Keywords:

electroslag surfacing, carbide, niobium, composites, wear resistance, microstructure, hardness, porosity, tribotechnology, crystallizerAbstract

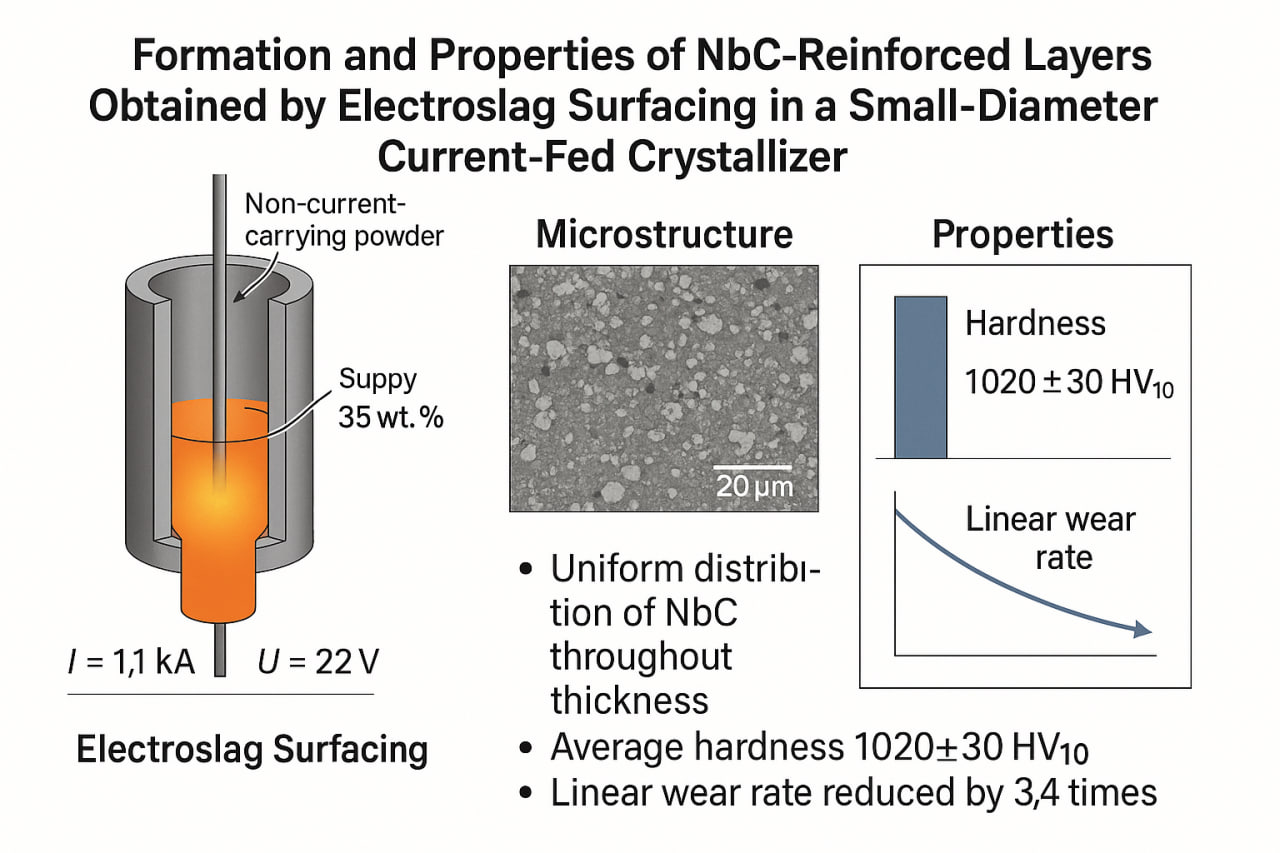

The object of research is the process of forming NbC-reinforced composite layers by electroslag surfacing (ESS) in a small-diameter current-fed crystallizer (CFC). The problem being solved is the stable introduction of finely dispersed NbC into a small-diameter slag bath without dissolution and agglomeration, achieving uniform reinforcement, low porosity and high wear resistance.

The research is aimed at experimentally determining the microstructure, phase composition, hardness, porosity, and abrasive wear resistance of layers formed under controlled ESS conditions using powder wire containing 35 wt.% NbC, and justifying the technological feasibility of the process in small-diameter CFC.

The process was implemented in two-section CFC Ø 65–85 mm under the following conditions: I = 1.1 kA; U = 22 V; feed rate Vsupply = 2.0 m · min⁻¹; melting duration 45 s; Tbath = 1600–1700°C. Morphology and chemical homogeneity were determined by optical microscopy and SEM-EDS; phase composition – by X-ray diffraction; hardness – by Vickers HV10; abrasive wear resistance – according to ASTM G99.

Layers of 2.0 ± 0.2 mm without macro-cracks and slag inclusions were obtained, with a uniform distribution of NbC (≈ 2–5 μm) throughout the thickness. The average hardness is 1020 ± 30 HV10 (≈ ×3 compared to steel 20), the linear wear rate is reduced by 3.4 times, porosity is ≤ 0.8 vol.% while maintaining high adhesive strength. It has been confirmed that the controlled feeding of non-current-carrying powder wire into the most heated zone of the bath ensures reproducible transfer of the refractory phase and prevents its dissolution and coarsening. The agreed microstructural features correlate with an increase in hardness and a decrease in wear, confirming the cause-and-effect relationship “structure → properties”.

The proposed technology can be implemented on existing ESS installations without re-equipment and is recommended for the restoration of parts operating under conditions of abrasive wear, with the potential for scaling up by regulating modes and controlling slag composition.

References

- Kuskov, Yu. M., Gordan, G. N., Bogajchuk, I. L., Kajda, T. V. (2015). Electroslag surfacing using discrete materials of different methods of manufacture. The Paton Welding Journal, 5-6, 30–33. https://doi.org/10.15407/tpwj2015.06.06

- Goryslavets, Yu. M., Bondar, O. I., Proskudin, V. M., Kuskov, Yu. M., Rymar, S. V., Netyaha, A. V. (2022). Modeling of electromagnetic processes in a sectional crystalizer for electroslag surfacing of metal. Tekhnichna Elektrodynamika, 4, 64–68. https://doi.org/10.15407/techned2022.04.064

- Kuskov, Yu. M., Shevchenko, V. Yu., Korzhik, V. M. (2021). Modernization of ESR furnaces into installations for ESS of mill rolls in a current-carrying mould. Electrometallurgy Today, 3, 9–12. https://doi.org/10.37434/sem2021.03.02

- Bilonik, I. M., Kapustian, O. Ye., Bilonik, D. I., Shumikin, S. O., Shumylov, O. A., Hubar, Ye. Ya. (2021). Manufacture by electroslag surfacing of the impact part of the hammer of the mechanism for shaking electrical precipitators. Reporter of the Priazovskyi State Technical University. Section: Technical sciences, 42, 14–21. https://doi.org/10.31498/2225-6733.42.2021.240566

- Babinets, A. A., Ryabtsev, I. O., Lentyugov, I. P., Bogaichuk, I. L. (2022). Influence of microalloying with boron on the structure and properties of deposited metal of the type of tool steel 25Kh5FMS. Automatic Welding, 6, 3–10. https://doi.org/10.37434/as2022.06.01

- Bely, A. I., Zhudra, A. P., Dzykovich, V. I., Petrov, V. V. (2018). Electrodes for arc hardfacing of composite alloys. The Paton Welding Journal, 1, 29–32. https://doi.org/10.15407/tpwj2018.01.06

- Student, M. M., Voytovych, A. A., Sirak, Ya. Ya., Gvozdetskyi, V. M. (2020). Development of new electrode materials, methods of restoration and protection of thin-walled parts of equipment, which are operated under the conditions of abrasive and gas-abrasive wear. The Paton Welding Journal, 10, 31–34. https://doi.org/10.37434/tpwj2020.10.06

- Shtefan, V. V., Epifanova, A. S., Koval’ova, A. A., Bairachnyi, B. I. (2017). Electrolytic Deposition of Highly Hard Coatings of a Cobalt–Molybdenum Alloy. Materials Science, 53 (1), 47–54. https://doi.org/10.1007/s11003-017-0042-6

- Babinets, A. A., Ryabtsev, I. O. (2021). Classification of methods of modification and microalloying of deposited metal (Review). The Paton Welding Journal, 9, 2–8. https://doi.org/10.37434/tpwj2021.09.01

- Babinets, A. A., Ryabtsev, I. O. (2021). Influence of modification and microalloying on deposited metal structure and properties (Review). The Paton Welding Journal, 10, 3–10. https://doi.org/10.37434/tpwj2021.10.01

- Holovko, V. V., Ermolenko, D. Yu., Stepanyuk, S. M. (2020). The influence of introducing refractory compounds into the weld pool on the weld metal dendritic structure. Automatic Welding, 6, 3–10. https://doi.org/10.37434/as2020.06.01

- Glotka, O. (2021). Prediction carbides composition in nickel-based superalloys directional crystallization. Innovative Materials and Technologies in Metallurgy and Mechanical Engineering, 2, 13–21. https://doi.org/10.15588/1607-6885-2020-2-2

- Dudnikov, A. A., Dudnikov, I. A., Dudnyk, V. V., Burlaka, O. A. (2021). Methods of restoring parts of agricultural machines. Scientific Progress & Innovations, (2), 280–285. https://doi.org/10.31210/visnyk2021.02.37

- Bilous, V. Yu., Pashynskyi, V. V., Berezos, V. O., Selyn, R. V., Vrzhyzhevskyi, E. L. (2022). Structure and properties of welded joints of steel 20 modified by nanoparticles of tungsten carbide. Electrometallurgy Today, 1, 47–55. https://doi.org/10.37434/sem2022.01.06

- Liang, J. W., Shen, Y. F., Misra, R. D. K., Liaw, P. K. (2021). High strength-superplasticity combination of ultrafine-grained ferritic steel: The significant role of nanoscale carbides. Journal of Materials Science & Technology, 83, 131–144. https://doi.org/10.1016/j.jmst.2020.11.078

- Akhonin, S. V., Berezos, V. O., Severin, A. Yu., Gadzira, M. P., Timoshenko, Ya. G., Davidchuk, N. K. (2020). Producing by electron beam melting the ingots of iron alloyed with silicon carbide. Electrometallurgy Today, 3, 24–29. https://doi.org/10.37434/sem2020.03.03

- Sisodia, R. P. S., Gáspár, M. (2021). Experimental assessment of microstructure and mechanical properties of electron beam welded S960M high strength structural steel. Manufacturing Letters, 29, 108–112. https://doi.org/10.1016/j.mfglet.2021.05.004

- Bhowmik, A., Zhai, W., Zhou, W., Nai, S. M. L. (2021). Characterization of carbide particle-reinforced 316L stainless steel fabricated by selective laser melting. Materials Characterization, 179, 111360. https://doi.org/10.1016/j.matchar.2021.111360

- Kuskov, Yu. M., Soloviov, V. G., Zhdanov, V. A. (2017). Electroslag surfacing of end faces with large-section electrode in current-supplying mould. The Paton Welding Journal, 12, 29–32. https://doi.org/10.15407/tpwj2017.12.05

- Kuskov, Yu. M. (2018). Influence of flux composition on the process of electroslag surfacing of end faces with discrete feeding of filler material. The Paton Welding Journal, 1, 33–37. https://doi.org/10.15407/tpwj2018.01.07

- ASTM G99-17. Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus (2023). ASTM International. https://doi.org/10.1520/g0099-17

- Netyaga, A. V., Kuskov, Yu. M., Proskudin, V. M., Zhdanov, V. A., Lantyugov, I. P. (2021). Formation of a layer of high-chromium cast iron in current-conducting mould of a square cross-section at electroslag surfacing. Electrometallurgy Today, 4, 16–19. https://doi.org/10.37434/sem2021.04.02

- Pereira, V. S. M., Davis, T. P., Mayoral, M. H., Kumar, A., Schut, H., Sietsma, J. (2022). Investigation of coarsening of oxide nanoparticles at 1400 K and its effect on the microstructure formation of an ODS Eurofer steel. Materials Characterization, 185, 111723. https://doi.org/10.1016/j.matchar.2022.111723

- Rybalko, I., Saychuk, O., Zakharov, A., Borovyk, O. (2023). The process of electroslig soldering using electrode powder wires. International Science Journal of Engineering & Agriculture, 2 (1), 1–9. https://doi.org/10.46299/j.isjea.20230201.01

- Sydow, Z., Sydow, M., Wojciechowski, Ł., Bieńczak, K. (2021). Tribological Performance of Composites Reinforced with the Agricultural, Industrial and Post-Consumer Wastes: A Review. Materials, 14 (8), 1863. https://doi.org/10.3390/ma14081863

- Cuppari, M., Santos, S. (2016). Physical Properties of the NbC Carbide. Metals, 6 (10), 250. https://doi.org/10.3390/met6100250

- Fedorov, P. P., Yarotskaya, E. G. (2021). Zirconium dioxide. Review. Condensed Matter and Interphases, 23 (2), 169–187. https://doi.org/10.17308/kcmf.2021.23/3427

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Oleksandr Saichuk, Olena Borovyk, Vadym Borovyk, Andrii Zakharov, Mykola Kapustianskyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.