Considering sawdust as a potential raw material for climate change mitigation in indoor environment

DOI:

https://doi.org/10.15587/2706-5448.2022.270479Keywords:

sawdust, thermal properties, composite material, climate change mitigation, indoor environmentAbstract

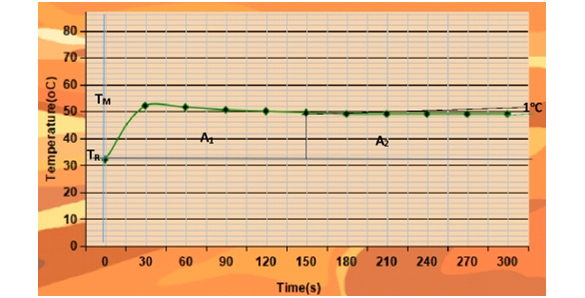

The object of the study is sawdust as a potential raw material for climate change mitigation in the indoor environment. The method of the mixture was used to determine the specific heat capacity of the sawdust sample, while its thermal conductivity was determined using the Lee disc method. The results of the study showed that the specific heat capacity of the sawdust is 54.9271 J·g–1·K–1 and that of thermal conductivity is 0.12 W/m·K. The implication of the results is that Sawdust needs about 54.9271 J·g–1·K–1 to raise its unit mass by 1 °C and a comparably very low thermal conductivity of 0.12 W/m·K. Sawdust can be used as a composite material for roofing, and ceilings to drastically reduce the rate at which the heat energy from the sun is transferred into the indoor environment and consequently reduce the effects of climate change on the indoor environment. Sawdust that is not properly managed or disposed can pose serious problems to aquatic and terrestrial ecosystems, fuel fire outbreaks and health problems such as severe allergic reactions. Therefore, discovering other reuse options for sawdust will reduce the problems it poses to the environment.

Supporting Agency

- Presentation of research in the form of publication through financial support in the form of a grant from SUES (Support to Ukrainian Editorial Staff).

References

- Health topics/climate change (2021). WHO. Available at: https://www.who.int/health-topics/climate-change#tab=tab_1 Last accessed: 20.03.2022

- Fourth climate Assessment V(ii) (2017). USGCRP. Available at: https://www.globalchange.gov/nca4 Last accessed: 20.03.2022

- Harrison, C. A., Thornton, R. G., Lawrence, D. M., Kinnersly, R. I., Ayres, J. G. (2002). Personal exposure monitoring of particulate matter, nitrogen dioxide, and carbon monoxide, including susceptible groups. Occupational and Environmental Medicine, 59 (10), 671–679. doi: https://doi.org/10.1136/oem.59.10.671

- Ghosh, B., Das, B., Soni, B., Saurav, A. (2018). Experimental investigation on the feasibility of using sawdust as partial replacement of fine aggregate in concrete. School of Civil Engineering, Kalinga Institute of Industrial Technology. doi: https://doi.org/10.13140/RG.2.2.15053.95206

- Lennox, J. A., Asitok, A., John, G. E., Etim, B. T. (2019). Characterization of products from sawdust biodegradation using selected microbial culture isolated from it. African Journal of Biotechnology, 18 (29), 857–864.

- Ogundipe, O. M., Adekanmi, J. S., Akinkurolere, O. O., Ale, P. O. (2019). Effect of Compactive Efforts on Strength of Laterites Stabilized with Sawdust Ash. Civil Engineering Journal, 5 (11), 2502–2514. doi: https://doi.org/10.28991/cej-2019-03091428

- Bhatti, P., Newcomer, L., Onstad, L., Teschke, K., Camp, J., Morgan, M., Vaughan, T. L. (2010). Wood dust exposure and risk of lung cancer. Occupational and Environmental Medicine, 68 (8), 599–604. doi: https://doi.org/10.1136/oem.2010.060004

- Owoyemi, J. M., Zakariya, H. O., Elegbede, I. O. (2016). Sustainable wood waste management in Nigeria. Environmental & Socio-Economic Studies, 4 (3), 1–9. doi: https://doi.org/10.1515/environ-2016-0012

- Hollamby, A. (2010). The dangers of sawdust. Hazardex. Available at: https://www.hazardexonthenet.net/article/28722/The-dangers-of-wood-dust.aspx

- Prusty, J. K., Patro, S. K., Basarkar, S. S. (2016). Concrete using agro-waste as fine aggregate for sustainable built environment – A review. International Journal of Sustainable Built Environment, 5 (2), 312–333. doi: https://doi.org/10.1016/j.ijsbe.2016.06.003

- Ignasher, J. (2022). Ice – The cold harvest. The Smithfield Times. Available at: https://smithfieldtimesri.net/wp-content/uploads/2021/12/ST-Jan-2022-low-res.pdf

- Kim, G.-H., Shin, J.-M., Kim, S., Shin, Y. (2013). Comparison of School Building Construction Costs Estimation Methods Using Regression Analysis, Neural Network, and Support Vector Machine. Journal of Building Construction and Planning Research, 1 (1), 1–7. doi: https://doi.org/10.4236/jbcpr.2013.11001

- Mwango, A., Kambole, C. (2019). Engineering Characteristics and Potential Increased Utilisation of Sawdust Composites in Construction – A Review. Journal of Building Construction and Planning Research, 7 (3), 59–88. doi: https://doi.org/10.4236/jbcpr.2019.73005

- Sahmoune, M. N., Yeddou, A. R. (2016). Potential of sawdust materials for the removal of dyes and heavy metals: examination of isotherms and kinetics. Desalination and Water Treatment, 57 (50), 24019–24034. doi: https://doi.org/10.1080/19443994.2015.1135824

- Meez, E., Rahdar, A., Kyzas, G. Z. (2021). Sawdust for the Removal of Heavy Metals from Water: A Review. Molecules, 26 (14), 4318. doi: https://doi.org/10.3390/molecules26144318

- Yang, H., Wang, Y., Liu, Z., Liang, D., Liu, F., Zhang, W., Di, X., Wang, C., Ho, S.-H., Chen, W.-H. (2017). Enhanced thermal conductivity of waste sawdust-based composite phase change materials with expanded graphite for thermal energy storage. Bioresources and Bioprocessing, 4 (1). doi: https://doi.org/10.1186/s40643-017-0182-4

- Arsenic, metals, fibres and dusts. IARC Working Group on the Evaluation of Carcinogenic Risks to Humans (2012). Lyon (FR): International Agency for Research on Cancer. IARC Monographs on the Evaluation of Carcinogenic Risks to Humans, No. 100C. Wood dust. Available at: https://www.ncbi.nlm.nih.gov/books/NBK304376/

- Aigbomian, P. E. (2013). Development of wood-crete building material. Brunel University.

- Mogaji, P. B., Ayodeji, S. P., Olatise, A. D., Oladele, I. O. (2017). Investigation of the properties and production of sawdust ceiling tile using polystyrene as a binder. African Journal of Science, Technology, Innovation and Development, 9 (6), 655–659. doi: https://doi.org/10.1080/20421338.2017.1352158

- Bentchikou, M., Guidoum, A., Scrivener, K., Silhadi, K., Hanini, S. (2012). Effect of recycled cellulose fibres on the properties of lightweight cement composite matrix. Construction and Building Materials, 34, 451–456. doi: https://doi.org/10.1016/j.conbuildmat.2012.02.097

- Charai, M., Sghiouri, H., Mezrhab, A., Karkri, M., Elhammouti, K., Nasri, H. (2020). Thermal Performance and Characterization of a Sawdust-Clay Composite Material. Procedia Manufacturing, 46, 690–697. doi: https://doi.org/10.1016/j.promfg.2020.03.098

- Folaranmi, J. (2009). Effect of additives on the thermal conductivity of clay. Minna. Available at: http://ljs.academicdirect.org/A14/074_077.htm

- Božiková, M., Kotoulek, P., Bilčík, M., Kubík, Ľ., Hlaváčová, Z., Hlaváč, P. (2021). Thermal properties of wood and wood composites made from wood waste. International Agrophysics, 35 (3), 251–256. doi: https://doi.org/10.31545/intagr/142472

- Ismail, I., Mardiani, M., Desy, L., Fauzi, F. (2014). Sawdust for thermal insulating building. Available at: https://www.semanticscholar.org/paper/Sawdust-for-Thermal-Insulation-Building-Ismail-Mardiani/1df8a519d873566450c830ffb2b878dcc7dca8d6

- Oluyamo, S. S., Bello, O. R. (2014). Particle Sizes and Thermal Insulation Properties of Some Selected Wood Materials for Solar Device Applications. IOSR Journal of Applied Physics, 6 (2), 54–58. doi: https://doi.org/10.9790/4861-06215458

- Mortensen, L. C. (2001). Engineering materials for mechanical engineer technicians. Oxford University press.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 James J. Robert, Ayebaniminyo Epkete

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.