Research and comparative analysis of the qualitative parameters of food powders produced from grain raw materials using an improved jet mill

DOI:

https://doi.org/10.15587/2706-5448.2022.271557Keywords:

whole grain flour, air milling, jet mill, flour quality analysis, wheat, buckwheat, bran, dietary productsAbstract

The object of the study is samples of food powders obtained by grinding the products of the collection and processing of a number of grain crops, using air-grinding technology in an improved jet mill. One of the most important problems of the modern food industry is that for the production of flour from cereals endosperm is used while the most important nutrients are found in shells and the germ of the grain.

As a result of its grinding in conventional mills, common at existing mills, large pieces of bran and a large variation in the particle size of the grinding products are obtained, and this method is energy-intensive.

According to the authors, the best solution to ensure truly whole grain grinding – that is, grinding grains with shells – is air grinding in jet mills. An improved jet mill makes it possible to grind both endosperm and grain shells into flour of the same consistency. From the same amount of raw material, therefore, it is possible to produce approximately 30 % more final grinding products. It is also important that the improved jet mill, under proven conditions, spends no more energy for grinding than a conventional mill.

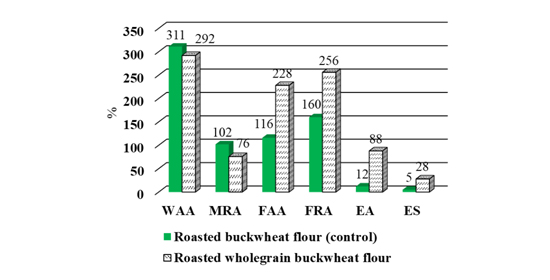

For research, the most popular products ground in such a mill were taken – wheat flour (black grain), buckwheat flour (from roasted buckwheat) and wheat bran. The first two products are whole grain milled, and the bran is produced from the collapse of wheat grown in accordance with the requirements of organic farming. Samples of powders obtained by grinding these products in an improved jet mill were compared with control samples – produced from similar raw materials in a roller mill – the most common design in service with mills. Physical indicators of the powders, thermophysical properties and biotechnological parameters were carried out.

The obtained results allow to state that whole grain grinding produced on an improved jet mill has the characteristics better or close to standard types of flour produced on conventional mills. It allows them to be used without significant changes in the formulation of products with their addition (bakery, pasta, etc.), and also to create new dietary, healthy products rich in biologically active substances.

References

- Gao, W., Chen, F., Wang, X., Meng, Q. (2020). Recent advances in processing food powders by using superfine grinding techniques: A review. Comprehensive Reviews in Food Science and Food Safety, 19 (4), 2222–2255. doi: https://doi.org/10.1111/1541-4337.12580

- Chen, T., Zhang, M., Bhandari, B., Yang, Z. (2017). Micronization and nanosizing of particles for an enhanced quality of food: A review. Critical Reviews in Food Science and Nutrition, 58 (6), 993–1001. doi: https://doi.org/10.1080/10408398.2016.1236238

- Zhao, G., Liang, X., Wang, C., Liao, Z., Xiong, Z., Li, Z. (2014). Effect of superfine pulverization on physicochemical and medicinal properties of Qili Powder. Revista Brasileira de Farmacognosia, 24 (5), 584–590. doi: https://doi.org/10.1016/j.bjp.2014.09.006

- Angelidis, G., Protonotariou, S., Mandala, I., Rosell, C. M. (2015). Jet milling effect on wheat flour characteristics and starch hydrolysis. Journal of Food Science and Technology, 53 (1), 784–791. doi: https://doi.org/10.1007/s13197-015-1990-1

- Kang, M. J., Kim, M. J., Kwak, H. S., Kim, S. S. (2019). Effects of Milling Methods and Cultivars on Physicochemical Properties of Whole-Wheat Flour. Journal of Food Quality, 2019, 1–12. doi: https://doi.org/10.1155/2019/3416905

- Protonotariou, S., Drakos, A., Evageliou, V., Ritzoulis, C., Mandala, I. (2014). Sieving fractionation and jet mill micronization affect the functional properties of wheat flour. Journal of Food Engineering, 134, 24–29. doi: https://doi.org/10.1016/j.jfoodeng.2014.02.008

- Kim, B.-K., Cho, A.-R., Chun, Y.-G., Park, D.-J. (2012). Effect of microparticulated wheat bran on the physical properties of bread. International Journal of Food Sciences and Nutrition, 64 (1), 122–129. doi: https://doi.org/10.3109/09637486.2012.710890

- Lee, D., Kim, M. J., Kwak, H. S., Kim, S. S. (2020). Characteristics of Bread Made of Various Substitution Ratios of Bran Pulverized by Hammer Mill or Jet Mill. Foods, 9 (1), 48. doi: https://doi.org/10.3390/foods9010048

- Kovalenko, V. V. (2009). Pat. No. 88789 UA. Method and device for flour production. MPK: B02C 9/00, B02C 19/06 (2006.01). No. a200702594. declareted: 25.09.2008; published: 25.11.2009, Bul. No. 18.

- Shi, L., Li, W., Sun, J., Qiu, Y., Wei, X., Luan, G., Hu, Y., Tatsumi, E. (2016). Grinding of maize: The effects of fine grinding on compositional, functional and physicochemical properties of maize flour. Journal of Cereal Science, 68, 25–30. doi: https://doi.org/10.1016/j.jcs.2015.11.004

- Hareland, G. A. (1994). Evaluation of Flour Particle Size Distribution by Laser Diffraction, Sieve Analysis and Near-infrared Reflectance Spectroscopy. Journal of Cereal Science, 20 (2), 183–190. doi: https://doi.org/10.1006/jcrs.1994.1058

- Augustin, M., Sanguansri, P.; Steve, L. T. (Ed.) (2009). Nanostructured materials in the food industry. Advances in Food and Nutrition Research. Academic, 183–213. doi: https://doi.org/10.1016/s1043-4526(09)58005-9

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Sun Changgao, Oleh Olkhovikov, Gao Xiaojin, Andrii Marynin, Zhang Sichen, Anastasiia Shevchenko, Sun Botong, Zhao Yue

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.