Concrete manufacturing with a low CO2 footprint

DOI:

https://doi.org/10.15587/2706-5448.2023.281246Keywords:

cement production, carbon dioxide emissions, alternative raw materials, building materials, Net Zero CO2, clinker-factorAbstract

The object of the research is the current state of the climate action strategy for cement and concrete production, including possible levers for reducing CO2 emissions.

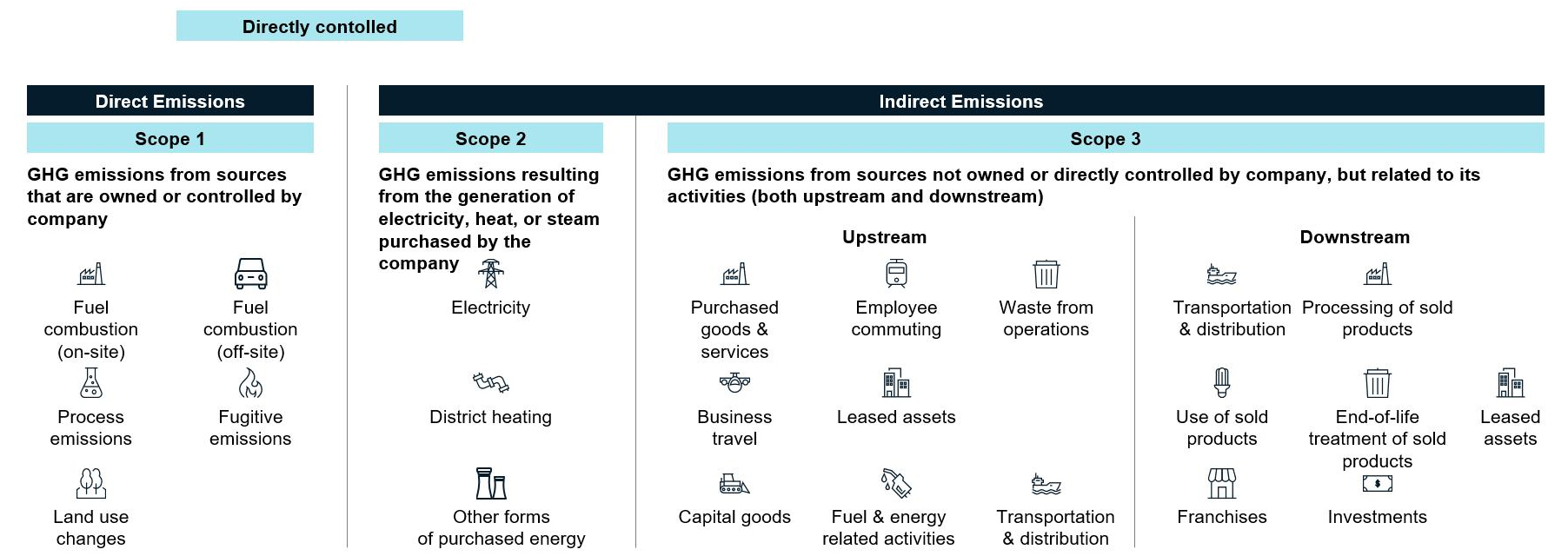

It has been determined that the main source of carbon dioxide emissions per tonne of Portland cement, and subsequently per cubic metre of concrete, is the decarbonization of calcium carbonate, the main raw material component of Portland cement clinker. It also involves the combustion of fossil fuels, which are necessary for the decarbonization and firing of raw materials. Therefore, Portland cement with a reduced content of Portland cement clinker is considered as a solution for concrete manufacturing with a low CO2 footprint. Additionally, the potential of Ukraine in the development of a sustainable Portland cement clinker production approach based on using alternative fuels and alternative raw materials, which will positively affect the total amount of CO2 per ton of clinker, was evaluated. Improved quality performance of cement has been identified as a key direction in product portfolio management to promote cements with a lower clinker factor by increasing the content of active mineral additives. It is shown that the production of concrete with increased strength and durability requirements based on cements saturated with active mineral additives is an important task. Since active mineral additives have different origins, not all of them available for use in cement production exhibit hydraulic properties inherent in Portland cement clinker.

Was investigated that «Complex Performance Testing System» (CPTS) as the main test method for evaluating the quality parameters of Portland cement with a reduced clinker factor in accordance with specific applications. This customer-oriented approach opens up the possibility of producing low-CO2 concrete. It has been shown that using the CPTS method, a reduction in the total amount of cement per cubic meter of concrete can be achieved, given the specified parameters of the concrete mix, which has a direct impact on the total amount of CO2/m3.

References

- Stashwick, S. (2022). Cut Carbon and Toxic Pollution, Make Cement Clean and Green. NRDC. Available at: https://www.nrdc.org/bio/veena-singla/cut-carbon-and-toxic-pollution-make-cement-clean-and-green

- Reiter, S. (2022). Transition to NET ZERO. McKinsey Sustainability. Available at: https://www.mckinsey.com/capabilities/sustainability/our-insights/spotting-green-business-opportunities-in-a-surging-net-zero-world/transition-to-net-zero/cement

- The Paris Agreement. United Nations. Available at: https://www.un.org/en/climatechange/paris-agreement

- Pro ratyfikatsiiu Paryzkoi uhody (2016). Zakon Ukrainy No. 1469-VIII 14.07.2016. Available at: https://zakon.rada.gov.ua/laws/show/1469-19#Text

- Pro Zvernennia Verkhovnoi Rady Ukrainy do Konferentsii Orhanizatsii Obiednanykh Natsii zi zminy klimatu (2021). Available at: https://zakon.rada.gov.ua/laws/show/1870-20#n14

- Ivaniuta, S. P., Yakushenko, L. M.; Smenkovskyi, A. Yu. (Ed.) (2022). Evropeiskyi zelenyi kurs i klimatychna polityka Ukrainy. Kyiv: NISD, 95.

- Bielohrad, А., Tokarchuk, V. (2019). Alternative fuels for cement production. Innovative Solutions in Modern Science, 8 (35), 31–37.

- Oecknick, J. (2020). Cements for use in Precast Concrete Industries – evaluation of their application potential in customer oriented way. Concrete Plant International.

- Oecknick, J., Niehoff, D. (1997). The compressive strength of cement – a new laboratory mixer with an integrated consistency test installation. Betonwerk und Fertigteiltechnik, 78–83.

- Cement PSD and Water Demand (2021). GCP Applied Technologies. Available at: https://gcpat.vn/en-gb/about/news/blog/cement-psd-and-water-demand

- DSTU B V.2.7-46:2010. Tsementy zahalnobudivelnoho pryznachennia.

- DSTU B EN 197-1:2015. Tsement. Chastyna 1. Sklad, tekhnichni umovy ta kryterii vidpovidnosti dlia zvychainykh tsementiv (EN 197-1:2011, IDT)

- KSE institute. Zvit pro priami zbytky infrastruktury vid ruinuvan vnaslidok viiskoi ahresii rosii proty Ukrainy. Kyiv, 2022.

- CEN EN 197-6:2023. Cement – Part 6: Cement with recycled building materials.

- CEN EN 197-5:2021. Cement Portland-composite cement CEM II/C-M and Composite cement CEM VI.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Anastasiia Bielohrad

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.