Development of textile structures using 3D prototyping technologies

DOI:

https://doi.org/10.15587/2706-5448.2025.327068Keywords:

3D prototyping, textile structures, additive manufacturing, spherical joints, pseudotextiles, material flexibilityAbstract

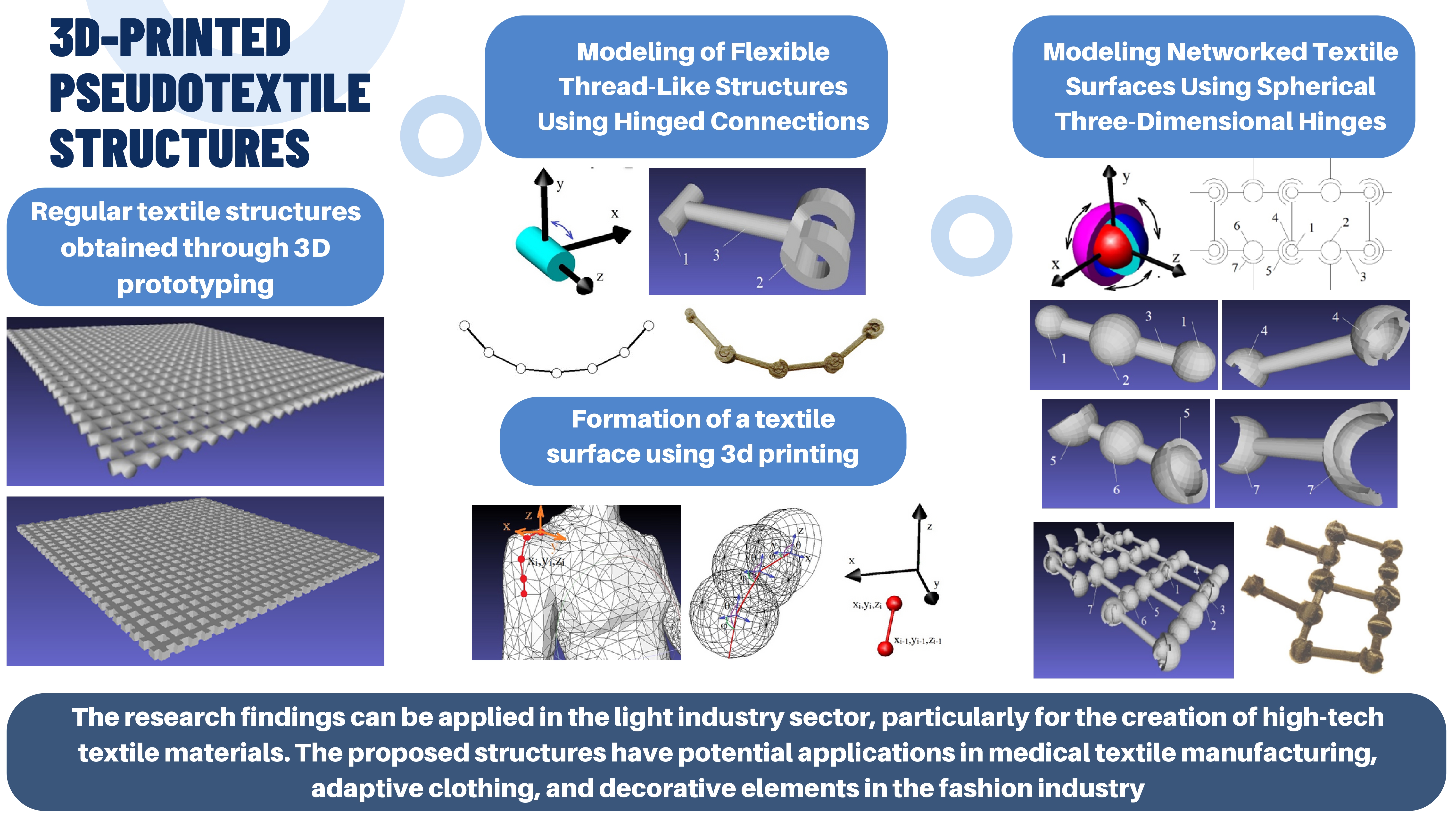

The object of the research is pseudotextile mesh structures with three-dimensional hinged joints, manufactured by 3D prototyping methods. One of the main tasks in the field of 3D printing of textile materials is to ensure their flexibility, elasticity and adaptability to the shape of the human body. Materials produced by traditional 3D printing methods have high rigidity, which limits their application in the light industry. During the study, a concept for creating pseudotextile materials based on flexible network structures using spherical three-dimensional hinges was developed. The proposed structure allows for achieve the necessary flexibility and deformation capabilities characteristic of traditional textile materials. Modeling and experimental samples demonstrated that structures with three-layer hinged joints provide spatial variability of shape, while the use of eccentricity in the hinges allows to adjust the rigidity of the structures. The obtained results can be attributed to the use of three-level spherical hinge joints, which provide spatial mobility of individual elements of the structure, as well as numerical modeling to optimize the sizes of structural elements. The implemented models confirm that the mechanical properties of the synthesized structures can be controlled by changing their geometry. The developed structures can be utilized in the clothing production where high flexibility of the material is required, as well as in the creation of adaptive textile products for medical purposes, in particular for compression therapy or automated massage. Additionally, such materials can be used in the decorative design of fashion products.

References

- Tan, Z., Lin, S., Wang, Z. (2024). Cluster Size Intelligence Prediction System for Young Women’s Clothing Using 3D Body Scan Data. Mathematics, 12 (3), 497. https://doi.org/10.3390/math12030497

- Zheng, J., Potamias, R. A., Zafeiriou, S. (2024). Design2Cloth: 3D Cloth Generation from 2D Masks. 2024 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), 1748–1758. https://doi.org/10.1109/cvpr52733.2024.00172

- Nayak, R., Singh, A., Padhye, R., Wang, L. (2015). RFID in textile and clothing manufacturing: technology and challenges. Fashion and Textiles, 2 (1). https://doi.org/10.1186/s40691-015-0034-9

- Wang, W., Ho, H.-I., Guo, C., Rong, B., Grigorev, A., Song, J. et al. (2024). 4D-DRESS: A 4D Dataset of Real-World Human Clothing with Semantic Annotations. 2024 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), 550–560. https://doi.org/10.1109/cvpr52733.2024.00059

- Riabchykov, M., Mytsa, V., Ryabchykova, K. (2024). Artificial Intelligence as a Tool for the Development of Professional Competencies of a Fashion Industry Specialist. Information Technology for Education, Science, and Technics. Cham: Springer, 297–310. https://doi.org/10.1007/978-3-031-71804-5_20

- Balakrishnan, H. K., Alexander, R., Guijt, R. M. (2025). 3D printing of analytical platforms: From prototyping to commercialization. 3D Printing in Analytical Chemistry, 87–100. https://doi.org/10.1016/b978-0-443-15675-5.00004-5

- Polishchuk, A., Slavinska, A., Polishchuk, O., Mytsa, V. (2023). Production of details of difficult designs of footwear and clothes with use of technologies of additive production. World Multidisciplinary Civil Engineering-Architecture-Urban Planning Symposium Wmcaus 2022, 2928, 040009. https://doi.org/10.1063/5.0172971

- Cui, T. Z., Raji, R. K., Han, J. L., Chen, Y. (2024). Application of 3D Printing Technology in Footwear Design and Manufacture – A Review of Developing Trends. Textile & Leather Review, 7, 1304–1321. https://doi.org/10.31881/tlr.2024.151

- Ochoa-V., D., Aroca, I., Lara, P., Paguay, A. (2024). Design for Six Sigma Applied for Adaptive Fashion Design with 3D Printing. Proceedings of the International Conference on Computer Science, Electronics and Industrial Engineering (CSEI 2023), 729–741. https://doi.org/10.1007/978-3-031-70981-4_48

- Vallejo, D. O., Aroca, I., Lara, P., Paguay, A. (2024). Mechanical Testing and Durability Evaluation of 3D Printed Magnetic Closures for Adaptive Fashion. Innovation and Research – Smart Technologies & Systems, 3–14. https://doi.org/10.1007/978-3-031-63437-6_1

- Manaia, J. P., Cerejo, F., Duarte, J. (2023). Revolutionising textile manufacturing: a comprehensive review on 3D and 4D printing technologies. Fashion and Textiles, 10 (1). https://doi.org/10.1186/s40691-023-00339-7

- Vuruskan, A., Ashdown, S. P. (2024). Comparison of actual and virtual pressure of athletic clothing in active poses. International Journal of Clothing Science and Technology, 37 (1), 1–21. https://doi.org/10.1108/ijcst-02-2024-0036

- Riabchykov, M., Mytsa, V., Bondarenko, M., Popova, T., Nechipor, S., Nikulina, A., Bondarenko, S. (2023). Formation of complex 3d surfaces scans for garment cad. Fibres and Textiles, 30 (3), 13–18. https://doi.org/10.15240/tul/008/2023-3-002

- Moustafa, S., Sultan, J., Wang, S., Nabil, S. (2024). Fabric-Lego: 3D-Printing Fabric-Based Lego-Compatible Designs for Assistive Wearables, Personalization, and Self-Expression. Designing Interactive Systems Conference, 209–213. https://doi.org/10.1145/3656156.3663705

- Park, S., Kim, D.-E. (2022). The application of 3D printing technology for developing a lumbar support garment for obese women. Textile Research Journal, 93 (7-8), 1712–1733. https://doi.org/10.1177/00405175221125944

- Riabchykov, M., Nazarchuk, L., Tkachuk, O., Stytsyuk, V. (2023). Creation of smart compression garment using magnetic nanotextiles. Research Journal of Textile and Apparel, 28 (4), 765–781. https://doi.org/10.1108/rjta-08-2022-0095

- Tufan Tolmaç, N., İşmal, Ö. E. (2023). A new era: 3D printing as an aesthetic language and creative tool in fashion and textile design. Research Journal of Textile and Apparel, 28 (4), 656–670. https://doi.org/10.1108/rjta-05-2022-0058

- Riabchykov, M., Mytsa, V., Tkachuk, O., Pakholiuk, O., Melnyk, D. (2024). Efficiency of Protective Textile Smart Systems Using Electronic Tags. Integrated Computer Technologies in Mechanical Engineering – 2023, 189–197. https://doi.org/10.1007/978-3-031-61415-6_16

- Zhang, M., Guo, Q., Li, Z., Zhou, Y., Zhao, S., Tong, Z. et al. (2023). Processable circularly polarized luminescence material enables flexible stereoscopic 3D imaging. Science Advances, 9 (43). https://doi.org/10.1126/sciadv.adi9944

- Dorsey, K. L., Roberts, S. F., Forman, J., Ishii, H. (2022). Analysis of DefeXtiles: a 3D printed textile towards garments and accessories. Journal of Micromechanics and Microengineering, 32 (3), 034005. https://doi.org/10.1088/1361-6439/ac4fad

- Yang, L., Meng, J., Wang, Y., Gao, X., Shi, G., Xue, T., Zhi, C. (2024). Direct ink writing-based cotton integration for enhanced mechanical and functional characteristics in 3D printed fabrics. Cellulose, 31 (4), 2685–2702. https://doi.org/10.1007/s10570-024-05742-x

- Li, S. (2024). Development and application of fused deposition molding 3D printing technology in textile and fashion design. Journal of Engineered Fibers and Fabrics, 19. https://doi.org/10.1177/15589250241266977

- Lekeckas, K., Stirbe, J., Ancutiene, K., Valusyte, R. (2023). Testing of 3D printing on textile fabrics for garments application within circular design. International Journal of Clothing Science and Technology, 35 (4), 627–647. https://doi.org/10.1108/ijcst-06-2022-0080

- He, C. (2024). Application and Development of 3D Printing Technology in Clothing Design. Applied Mathematics and Nonlinear Sciences, 9 (1). https://doi.org/10.2478/amns-2024-1199

- Wong, Y., Ho, C., Kan, C. (2024). Performance of Fused Deposition Modeling 3D Printed Fabric with Different Structures. 3D Printing and Additive Manufacturing. https://doi.org/10.1089/3dp.2023.0254

- Xiao, Y.-Q., Kan, C.-W. (2022). Review on Development and Application of 3D-Printing Technology in Textile and Fashion Design. Coatings, 12 (2), 267. https://doi.org/10.3390/coatings12020267

- Spahiu, T., Zlatev, Z., Ibrahimaj, E., Ilieva, J., Shehi, E. (2022). Drape of Composite Structures Made of Textile and 3D Printed Geometries. Machines, 10 (7), 587. https://doi.org/10.3390/machines10070587

- Sun, N., Mu, X., Zhao, K. (2024). Application of 3D Printing Technology in Customized Garment Production. Applied Mathematics and Nonlinear Sciences, 9 (1). https://doi.org/10.2478/amns-2024-1662

- Jung, J. Y., Chee, S., Sul, I. (2023). Prediction of optimal 3D printing orientation using vertically sparse voxelization and modified support structure tomography. International Journal of Clothing Science and Technology, 35 (5), 799–832. https://doi.org/10.1108/ijcst-04-2023-0041

- Wu, M., Zhi, C., Tu, L., Wang, Y., Dai, Y., Yu, L., Meng, J., He, X. (2021). Cotton-containing printing wires based on the two-dimensional braiding method for three-dimensional printing of clothing. Textile Research Journal, 92 (9-10), 1384–1393. https://doi.org/10.1177/00405175211059208

- Orlik, J., Neusius, D., Chakrabortty, A., Backes, S., Gries, T., Steiner, K. (2025). Modelling of flat pre-strain driven structures, folding to desired surface and application to 3D-printing on textiles. International Journal of Engineering Science, 208, 104201. https://doi.org/10.1016/j.ijengsci.2024.104201

- Liu, Z., Dong, F., Li, F. (2024). Numerical and experimental investigations on influence of spherical hinge mandrel on deformation characteristics of large diameter tube in small-radius NC rotary bending. The International Journal of Advanced Manufacturing Technology, 134 (11-12), 6001–6018. https://doi.org/10.1007/s00170-024-14537-0

- Guo, W., Yu, Y., Huang, M., Yang, J., Chen, W. (2024). Installation Accuracy Detection Method of Spherical Hinge Structure Based on 3D Point Cloud Registration. CICTP 2024, 3709–3719. https://doi.org/10.1061/9780784485484.353

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Viktoriia Mytsa, Mykola Riabchykov, Tetyana Popova, Anastasiia Nikulinа

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.