Comprehensive formation of leather semi-finished products using enzymes

DOI:

https://doi.org/10.15587/2706-5448.2025.344270Keywords:

enzymatic plasticization, enzymes of proteolytic and hydrolytic action, leather semi-finished product, physicochemical propertiesAbstract

The object of research is the process of complex formation of elastic leather using enzymes of proteolytic and hydrolytic action.

One of the most problematic areas is the decrease in the elasticity of the leather semi-finished product at the stage of its dehydration. Enzyme treatment increases the mobility of the microfibrillar structure of the semi-finished product due to the destruction of physical intermolecular bonds.

During the study, a proteolytic enzyme was used at the stage of bating the pelt and enzymes of hydrolytic action were used to treat the tanned chrome semi-finished product.

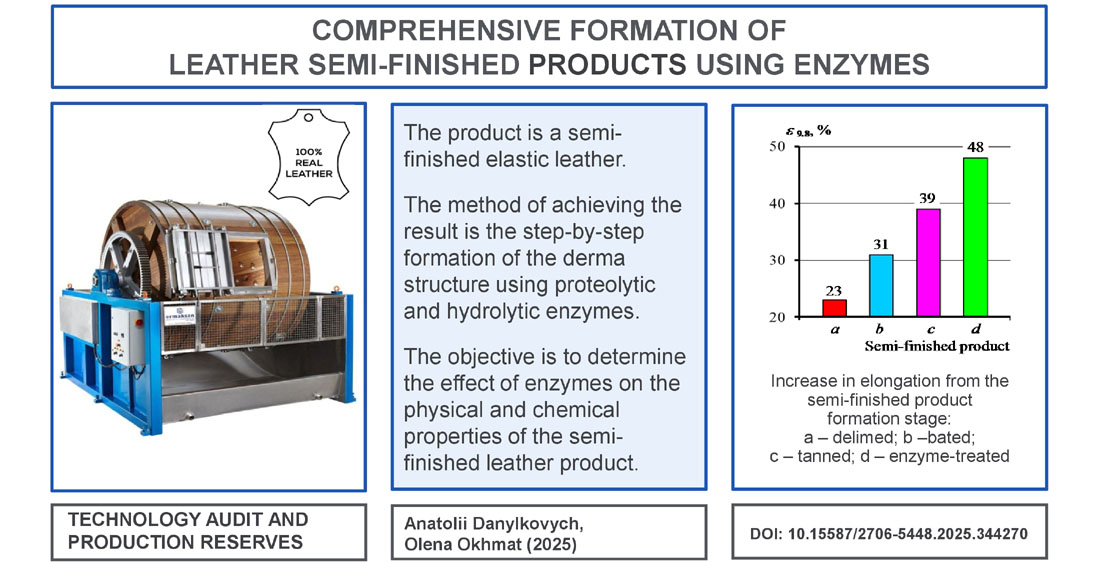

A semi-finished product was obtained, which is characterized by an increase in porosity compared to the original semi-finished product. The porosity of the semi-finished product increases by 22% in the case of using enzyme treatment at the bating stage and by 67% with repeated treatment of the tanned semi-finished product with enzymes. This is due to the fact that the proposed enzyme treatment promotes the removal of glycosaminoglycans from the dermis at the bating stage. Further use of enzymes after tanning of the semi-finished product contributes to the destruction of carbohydrate bonds with collagen macromolecules, which ensures an increase in its physicochemical properties. The peculiarity of this effect can be explained by the presence of an active center in enzymes, which forms enzyme-hydrocarbon-collagen complexes with carbohydrates and collagen macromolecules. Inside the formed complexes, the destruction of existing bonds occurs and the separation of carbohydrates from the collagen of the dermis.

This provides the possibility of obtaining a leather semi-finished product, which is characterized by an increase in the tensile strength and elongation at 9.8 MPa by 8.4 and 23.0%, respectively, and these indicators reach 20.7 MPa and 48.0% compared to the indicators of the tanned semi-finished product.

References

- de Castro Bizerra, V., Sales, M. B., Fernandes Melo, R. L., Andrade do Nascimento, J. G., Junior, J. B. et al. (2024). Opportunities for cleaner leather processing based on protease enzyme: Current evidence from an advanced bibliometric analysis. Renewable and Sustainable Energy Reviews, 191, 114162. https://doi.org/10.1016/j.rser.2023.114162

- Atamanova, A. A., Kolesnyk, T. O., Andreieva, O. A. (2020). Modern research on the properties and use of enzymes. Visnyk Khmelnytskoho Natsionalnoho Universytetu, 5 (267), 257–263. Available at: https://journals.khnu.km.ua/vestnik/?p=4652

- Wanyonyi, W. C., Mulaa, F. J.; Mamo, G., Mattiasson, B. (Eds.) (2019). Alkaliphilic Enzymes and Their Application in Novel Leather Processing Technology for Next-Generation Tanneries. Alkaliphiles in Biotechnology. Advances in Biochemical Engineering/Biotechnology. Cham: Springer, 195–220. https://doi.org/10.1007/10_2019_95

- Ma, J., Hou, X., Gao, D., Lv, B., Zhang, J. (2014). Greener approach to efficient leather soaking process: role of enzymes and their synergistic effect. Journal of Cleaner Production, 78, 226–232. https://doi.org/10.1016/j.jclepro.2014.04.058

- Khambhaty, Y. (2020). Applications of enzymes in leather processing. Environmental Chemistry Letters, 18 (3), 747–769. https://doi.org/10.1007/s10311-020-00971-5

- Dettmer, A., Schacker dos Anjos, P., Gutterres, M. (2013). Enzymes in the Leather Industry, A Special Review Paper. JALCA, 108, 146–158. Available at: https://journals.uc.edu/index.php/JALCA/article/view/3464

- Kolesnyk, T. O., Andreieva, O. A. (2020). Research of the process soaking of leather raw material in the presence of enzyme preparations. Visnyk Khmelnytskoho natsionalnoho universytetu, 2 (283), 251–254. Available at: https://journals.khnu.km.ua/vestnik/?p=1199

- Simion, D., Gaidău, C., Păun, G., Berechet, D. (2023). Applications of Enzymes as Ecologic Alternatives in the Leather Industry. Leather and Footwear Journal, 23 (2), 107–114. https://doi.org/10.24264/lfj.23.2.4

- Edmonds, R. (2008). Proteolytic depilation of lambskins. [Doctoral dissertation, Massey University]. Available at: https://mro.massey.ac.nz/bitstream/10179/892/1/Edmonds%20RL%202008%20as%20amended.pdf

- Afsar, A., Cetinkaya, F. (2008). Studies on the degreasing of skin by using enzyme in liming process. Indian Journal of Chemical Technology, 15 (5), 507–510. Available at: https://scispace.com/papers/studies-on-the-degreasing-of-skin-by-using-enzyme-in-liming-1ibihp0yhw

- Lyu, B., Cheng, K., Ma, J., Hou, X., Gao, D., Gao, H. et al. (2017). A cleaning and efficient approach to improve wet-blue sheepleather quality by enzymatic degreasing. Journal of Cleaner Production, 148, 701–708. https://doi.org/10.1016/j.jclepro.2017.01.170

- Briki, S., Hamdi, O., Landoulsi, A. (2016). Enzymatic dehairing of goat skins using alkaline protease from Bacillus sp. SB12. Protein Expression and Purification, 121, 9–16. https://doi.org/10.1016/j.pep.2015.12.021

- Skyba, M. Y. (2025). Clean technologies in tannery. Technologies and Engineering, 5 (22), 110–122. https://doi.org/10.30857/2786-5371.2024.5.11

- Choudhary, R. B., Jana, A. K., Jha, M. K. (2004). Enzyme technology applications in leather processing. Indian Journal of chemical technology, 11 (5), 659–671. Available at: https://scispace.com/papers/enzyme-technology-applications-in-leather-processing-ugvgeo7n3m

- Zhang, Y., Liu, H., Tang, K., Liu, J., Li, X. (2021). Effect of different ions in assisting protease to open the collagen fiber bundles in leather making. Journal of Cleaner Production, 293, 126017. https://doi.org/10.1016/j.jclepro.2021.126017

- Širvaitytė, J., Valeika, V., Beleška, K., Valeikienė, V. (2006). Bating of pelts after deliming with peracetic acid. Proceedings of the Estonian Academy of Sciences. Chemistry, 55 (2), 93–100. https://doi.org/10.3176/chem.2006.2.06

- Harkavenko, S. S., Statsenko, D. V., Zlotenko, B. M. (2016). Vykorystannia enzymiv u shkiriano-vzuttievomu vyrobnytstvi. Kyiv: KNUTD, 16–18.

- Kopytina, I., Andreyeva, O., Mokrousova, O., Okhmat, O. (2022). Enzymes and approaches to their application in the leather production. Herald of Khmelnytskyi National University. Technical Sciences, 313 (5), 227–232. https://doi.org/10.31891/2307-5732-2022-313-5-227-232

- Danylkovych, A. H., Lishchuk, V. I., Strembulevych, L. V. (2015). Suchasne vyrobnytstvo khutra. Kyiv: Fenik, 320. Available at: https://er.knutd.edu.ua/handle/123456789/1754

- Souza, F. R. de, Gutterres, M. (2012). Application of enzymes in leather processing: a comparison between chemical and coenzymatic processes. Brazilian Journal of Chemical Engineering, 29 (3), 473–482. https://doi.org/10.1590/s0104-66322012000300004

- Biškauskaitė, R., Valeika, V. (2023). Wet Blue Enzymatic Treatment and Its Effect on Leather Properties and Post-Tanning Processes. Materials, 16 (6), 2301. https://doi.org/10.3390/ma16062301

- Lasoń-Rydel, M., Sieczyńska, K., Gendaszewska, D., Ławińska, K., Olejnik, T. P. (2024). Use of enzymatic processes in the tanning of leather materials. AUTEX Research Journal, 24 (1). https://doi.org/10.1515/aut-2023-0012

- Biškauskaitė-Ulinskė, R., Valeika, V. (2025). Effect of Enzyme on Chromed Leather Dyeing With Acidic Dyes. Journal of Engineering, 2025 (1). https://doi.org/10.1155/je/8884546

- Danylkovych, A. H. (2006). Praktykum z khimii i tekhnolohii shkiry ta khutra. Kyiv: Feniks, 340.

- Danylkovych, A. H. (2016). Osnovni materialy i tekhnolohii vyrobnytstva shkiry. Kyiv: KNUTD, 175. Available at: https://er.knutd.edu.ua/bitstream/123456789/18043/1/20210713_301.pdf

- Mokrousova, E., Dzyazko, Y., Volfkovich, Y., Nikolskaya, N. (2016). Hierarchical structure of the derma affected by chemical treatment and filling with bentonite: Diagnostics with a method of standard contact porosimetry. Nanophysics, Nanophotonics, Surface Studies, and Applications: Selected Proceedings of the 3rd International Conference Nanotechnology and Nanomaterials (NANO2015). Cham: Springer International Publishing, 277–290. https://link.springer.com/chapter/10.1007/978-3-319-30737-4_23

- Pervaia, N. V. (2019). Assessment of the capability of leather for footwear upper to keep the shape after molding. Bulletin of the Kyiv National University of Technologies and Design. Technical Science Series, 3 (134), 62–72. https://doi.org/10.30857/1813-6796.2019.3.6

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Аnatolii Danylkovych, Olena Okhmat

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.