Analysis and assessment of potential risks in the production of enriched sugar

DOI:

https://doi.org/10.15587/2706-5448.2024.307282Keywords:

viburnum sugar, elderberry sugar, sea buckthorn sugar, rowan sugar, product quality, product safetyAbstract

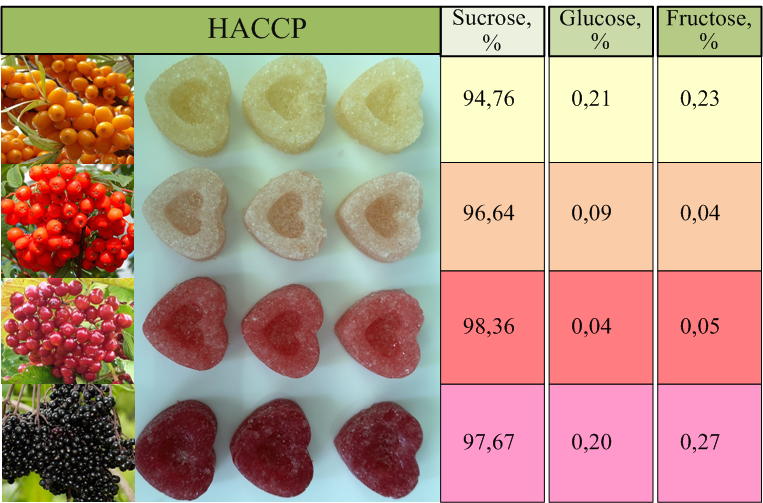

The object of research is the quality indicators of sugar enriched with derivatives of the processing of the fruits of wild plants (viburnum, mountain ash, sea buckthorn, black elder) and potential dangerous factors that may arise during its production. This study is aimed at the analysis and assessment of all risks that arise in the production of sugar enriched with derivatives of processing of wild raw materials. For the production of enriched sugar, pre-cleaned fruits were frozen at a temperature of –18±2 °С, and after defrosting, they were partially dehydrated by the method of osmotic dehydration. For this, a 70 % sugar solution with a temperature of 50±5 °C was used (hydromodule 1). The duration of osmotic dehydration was 1 hour. The derivative product formed as a result of osmotic dehydration of fruits (sugar solution) was used to enrich granulated sugar in the amount of 10 % by mass of sugar. After thorough mixing with the solution, the sugar was dried in a laboratory vacuum dryer and analyzed. Based on the principles of HACCP, a detailed description of the product and its use with a specific purpose has been developed. In particular, the description of all stages of production, from the initial materials to the processing and packaging processes, as well as the definition of all possible dangerous factors that can affect the safety and quality of products. The identification and assessment of all hazardous factors included the analysis of all possible threats to the safety and quality of products at each stage of production. To ensure the quality and safety of enriched sugar obtained from wild raw materials, an assessment of potential dangerous factors at all stages of production was carried out. A HACCP plan has been developed that allows effective management of critical control points and evaluation of the results of this management. This will allow potential manufacturers to produce safe and competitive products of high quality. The practical implementation of these proposals will allow bringing new products to the market - elderberry, sea buckthorn, rowan and viburnum sugar.

Supporting Agency

- The research was carried out within the scientific and technical work 0124U002836 «Development of technologies for the production of food products with added value based on the principles of sustainable development» at the expense of the executors.

References

- Saraiva, A., Carrascosa, C., Ramos, F., Raheem, D., Lopes, M., Raposo, A. (2023). Coconut Sugar: Chemical Analysis and Nutritional Profile; Health Impacts; Safety and Quality Control; Food Industry Applications. International Journal of Environmental Research and Public Health, 20 (4), 3671. doi: https://doi.org/10.3390/ijerph20043671

- Sundaram, M. S., Jagadeesh, K. (2020). Sugar Quality: Process Options to Address Sustainability of Sugar Industry. Sugar and Sugar Derivatives: Changing Consumer Preferences, 77–91. doi: https://doi.org/10.1007/978-981-15-6663-9_5

- Lee, J. S., Ramalingam, S., Jo, I. G., Kwon, Y. S., Bahuguna, A., Oh, Y. S. et al. (2018). Comparative study of the physicochemical, nutritional, and antioxidant properties of some commercial refined and non-centrifugal sugars. Food Research International, 109, 614–625. doi: https://doi.org/10.1016/j.foodres.2018.04.047

- Souliotis, A., Giazitzi, K., Boskou, G. (2018). A tool to benchmark the food safety management systems in Greece. Benchmarking: An International Journal, 25 (8), 3206–3224. doi: https://doi.org/10.1108/bij-02-2017-0028

- Ibrahim, O. O. (2020). Introduction to Hazard Analysis and Critical Control Points (HACCP). EC Microbiology, 16 (3), 1–7. Available at: https://www.researchgate.net/publication/340579693_Introduction_to_Hazard_Analysis_and_Critical_Control_Points_HACCP

- Motarjemi, Y., Warren, B. R. (2023). Hazard Analysis and Critical Control Point System (HACCP). Food Safety Management, 799–818. doi: https://doi.org/10.1016/b978-0-12-820013-1.00017-6

- Alamri, M. S., Qasem, A. A. A., Mohamed, A. A., Hussain, S., Ibraheem, M. A., Shamlan, G. et al. (2021). Food packaging’s materials: A food safety perspective. Saudi Journal of Biological Sciences, 28 (8), 4490–4499. doi: https://doi.org/10.1016/j.sjbs.2021.04.047

- Anggraeni, D., Najah, Z., Nurtiana, W., Putri, N. A. (2021). Hazard Analysis of Sate Bandeng as Indigenous Food From Banten. Joint Proceedings of the 2nd and the 3rd International Conference on Food Security Innovation (ICFSI 2018-2019). doi: https://doi.org/10.2991/absr.k.210304.034

- Sarah, S., Bujang, A., Ain, N., Nurfadzliyana, N. (2020). An overview of potential hazards and control measures of food delivery service activities. Advances in Transportation and Logistics Research, 3, 892–898. Available at: https://proceedings.itltrisakti.ac.id/index.php/ATLR/article/view/348

- Das, A. K., Nanda, P. K., Das, A., Biswas, S. (2019). Hazards and Safety Issues of Meat and Meat Products. Food Safety and Human Health, 145–168. doi: https://doi.org/10.1016/b978-0-12-816333-7.00006-0

- Molina, E., Benedé, S. (2022). Is There Evidence of Health Risks From Exposure to Micro- and Nanoplastics in Foods? Frontiers in Nutrition, 9. doi: https://doi.org/10.3389/fnut.2022.910094

- Pettoello-Mantovani, C., Olivieri, B. (2022). Food safety and public health within the frame of the EU legislation. Global Pediatrics, 2, 100020. doi: https://doi.org/10.1016/j.gpeds.2022.100020

- Pettoello-Mantovani, M., Mestrovic, J., Carrasco-Sanz, A., Hoey, H., Pop, T. L., Somekh, E. et al. (2022). Introduction to the Special Issue on Safe food for infants: the importance of pursuing integrated approaches to monitor and reduce the risks of biological, chemical, and physical hazards in infant food during the key developmental years. Global Pediatrics, 2, 100008. doi: https://doi.org/10.1016/j.gpeds.2022.100008

- DSTU 4623:2023. Sugar. The technical specifications. Kyiv. Available at: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=104333

- Samilyk, M., Korniienko, D., Bolgova, N., Sokolenko, V., Boqomol, N. (2022). Using derivative products from processing wild berries to enrich pressed sugar. Eastern-European Journal of Enterprise Technologies, 3 (11 (117)), 39–44. doi: https://doi.org/10.15587/1729-4061.2022.258127

- TU U 10.8-04718013-009:2023. Tsukor vitaminizovanyi presovanyi. Tekhnichni umovy. Sumy.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Maryna Samilyk, Daria Korniienko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.